15

Dymax SG-200 High-Flow Spray Gun System User Guide

psi (0 to 2 bar or 0 to 6.9 bar)

—

which can be installed if needed. If you are not sure of the

material/atomization pressure range at which you will run the system, start with the installed pressure gauge

and change to one of the alternative pressure gauges if needed.

Initial Setup of the Spray Gun

The SG-200 spray gun is designed for ease of setup. All air connections come pre-installed except for the

connection between the shop air and the air filter/regulator and the fluid line must be connected between the

materials reservoir and the spray gun. Before operation, check that the material lines and air lines and fitting

connections are secure and 100% inserted.

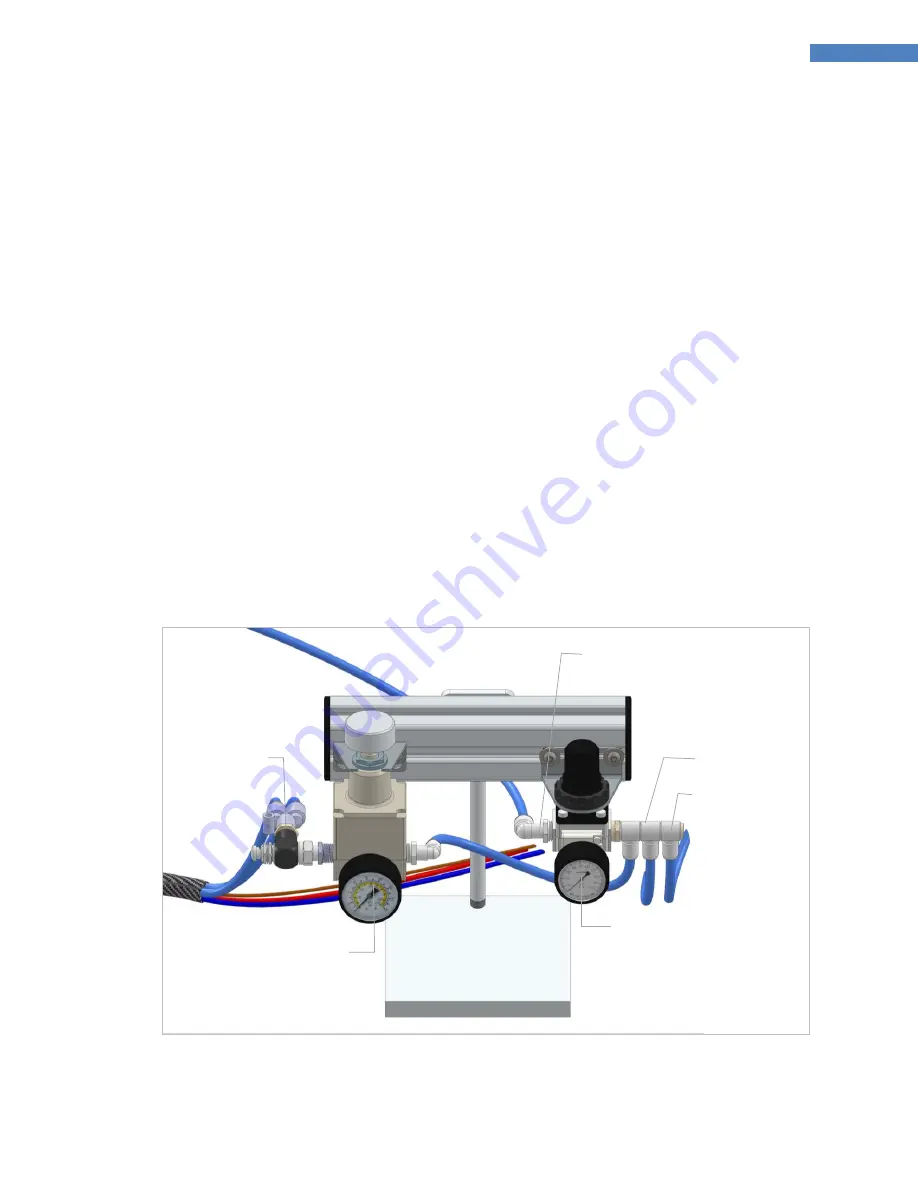

Connecting the Air Filter/Regulator

1.

Check to make sure the dual tubes from the atomizing head on the front of the SG-200 valve is connected

to the dual port of the atomizing control regulator. The air line between the atomizing control regulator

and material pressure regulator should also be pre-configured. (Figure 6)

2.

Securely mount the air filter/regulator in an upright position (filter bowl at the bottom) in accordance

with the OEM instructions supplied with the air filter/regulator. Failing to securely mount the inlet

pressure regulator in the upright position will prevent the regulator from removing moisture and

particulates from the incoming compressed air.

3.

Connect factory air to the air filter/regulator. Be sure the regulator outlet knob is in the off position.

Figure 6. Supply & Atomizing Control Valve Stand

Air Out to Reservoir

Dual Port

Atomizing Regulator

Material Pressure Regulator

Air Out to DVC-345

Connect to Air Filter/

Regulator