23

Dymax SG-200 High-Flow Spray Gun System User Guide

9.

Turn on the ram pump. Do NOT turn on the atomizing switch. Aim the SG-200 spray gun away from

people and unintended target objects. Purge the material into a container vessel by depressing the spray

gun trigger. Continue until all air is purged and a steady stream of material flows. This may take several

minutes.

10.

Flow rates should be evaluated and adjusted at this time. The psi of the ram pump and the material

regulator should be adjusted independently to meet the desired flow rates per material.

Do not exceed the psi ratings for the pump, regulator, or material. A suggested starter guide is listed

below, please check with Dymax Application Engineering for material details.

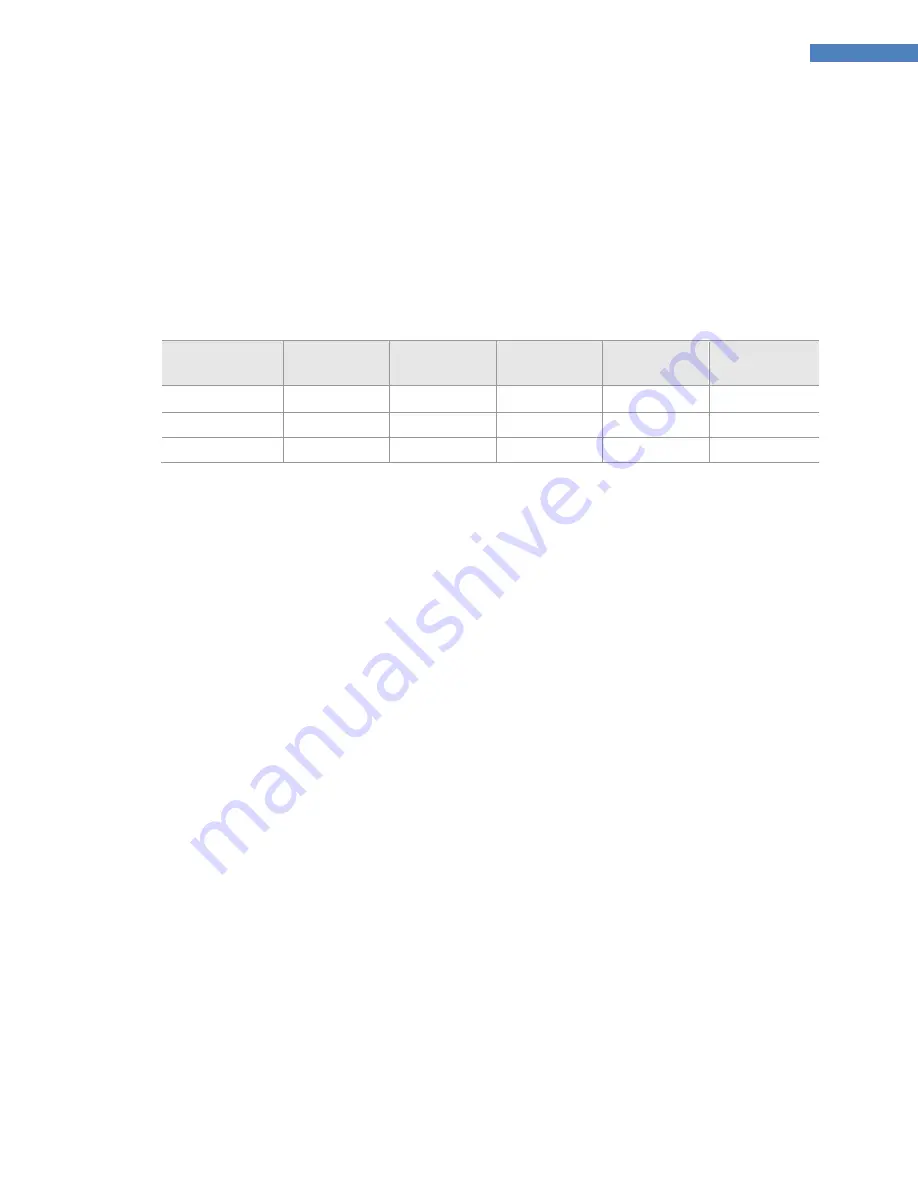

Table 1. PSI Ratings for Dispensing System Components

Viscosity, cP

RAM psi

(11:1 ratio)

Material psi

Atomizing psi

Tip Nozzle

Spray Diameter

(8-10

"

distance)

< 20,000

5-10

10-20

10-20

0.040"

8-10"

20,000 - 75,000

20-25

20-25

20-35

0.080"

6-8"

75,000 - 100,000 +

50-75

45-75

50-80

0.120"

6-8"

11.

Continue to run the pump and adjust settings until all air is purged from system.

12.

Record settings. Turn off the pail pump.

13.

Clean valve nozzle threads and securely replace nozzle and nozzle cap on the SG-200 spray gun.

NOTE:

Wear protective clothing, gloves, and hearing and eye protection when using the pail pump

system. Do not place hands near or inside of the ram pump. Refer to the Ram Pump Operator

’

s Manual

for repair, cleaning, and use instructions.

E

—

Systems with a Customer-Supplied Reservoir Retainer/Tank

If you are supplying your own reservoir retainer/tank, Dymax recommends reviewing the assembly procedures

presented above and choosing the assembly procedures that best matches your retainer/tank configuration.

Then adapt that assembly procedure to your system.