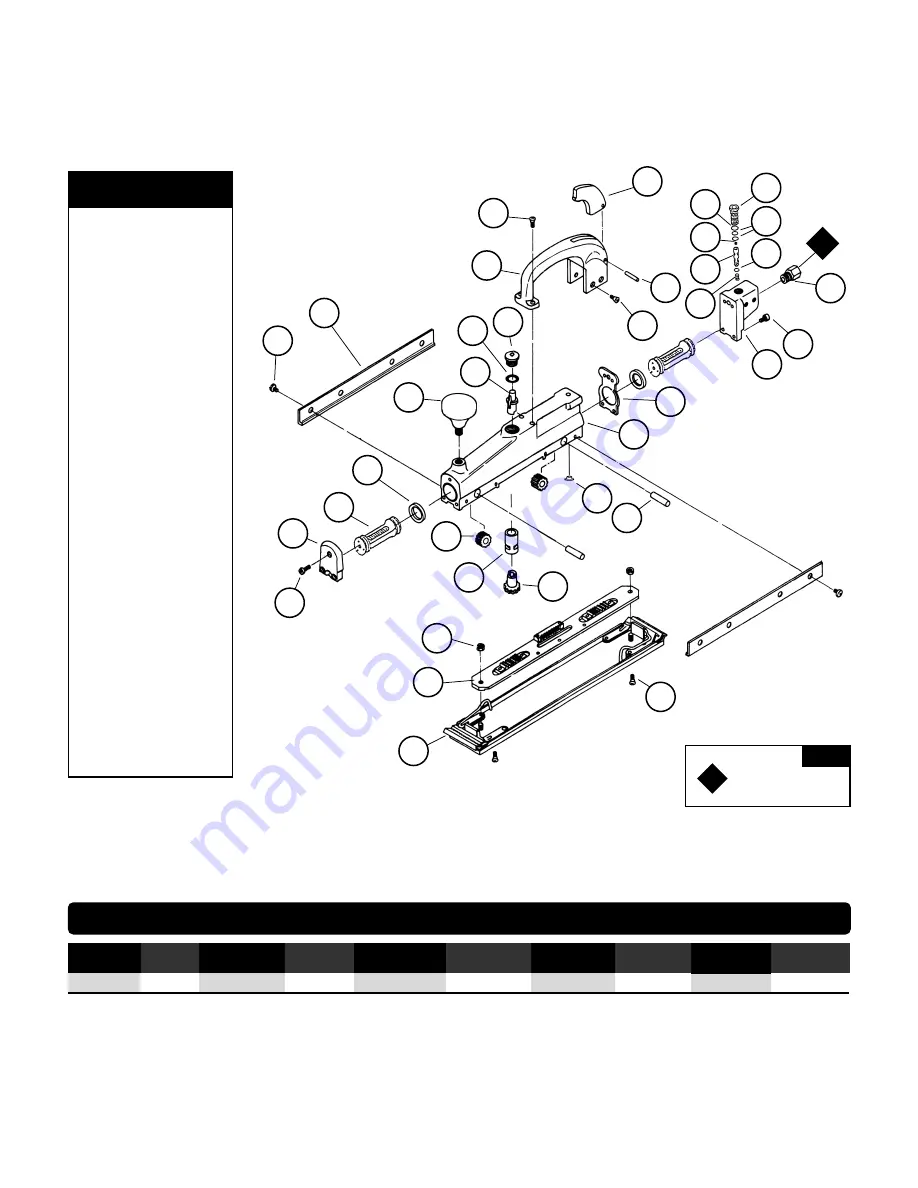

Long Board Sander

Complete Assembly

3

1

06060

Screw (7)

2

06101

Front Cap

3

06062

Piston (2)

4

06064

Piston Ring (2)

5

06071

Gear (2)

6

06076

Valve

7

06077

Actuator Gear

8

06085

Nut (2)

9

06087

Carrier

10

06088

Pad Assembly

11

06098

Screw (2)

12

06072

Gear Shaft (2)

13

06090

Screw (8)

14

06089

Side Strap (2)

15

06067

Knob

16

06075

Adjusting Shaft

17

06074

O-Ring (2)

18

06073

Plunger

19

06080

Handle

20

06081

Screw (2)

21

06082

Trigger

22

06083

Pin

23

06084

Screw (4)

24

06066

Housing

25

06091

Rear Gasket

26

06102

Valve Bushing

27

06103

O-Ring (2)

28

06061

Set Screw

29

06100

Valve Stem

30

06095

O-Ring

31

06096

Spring

32

06092

Rear Cap

33

06099

Inlet Adapter

34

06068

Wear Button (8)

KEY

O

1

O

Oil:

O

1

= Air Lube

1

2

3

9

4

13

14

20

21

19

22

23

27

28

29

31

30

17

26

33

32

1

18

17

24

34

25

16

15

12

11

10

8

5

6

7

Model: 18066

Note:

To order replacement parts

specify the

Model #

,

Serial #

and

SPM

of your air tool.

Index Key

No. Part # Description

Machine Specifications

Additional Specifications: Air Inlet Thread 1/4" NPT • Hose I.D. 3/8" (10 mm)

Sound Level is the pressure measurement according to the method outlined in ISO regulation ISO-15744

Model

Motor

Stroke Length

Sound

Max. Air Flow

Air Pressure

Weight

Length

Height

Paper Size

Number

SPM

Inch (mm)

Level

SCFM (LPM)

PSIG (Bars)

Pound (kg)

Inch (mm)

Inch (mm)

Inch

18066

2,500

1 (25)

93 dB(A)

14 (396)

90 (6.2)

5.6 (2.5)

16 (406)

6-1/8 (156)

2-3/4 x 17-1/2