Maintenance Instructions

Important:

To keep tool safe a preventative maintenance program is recommended whenever portable power tools are used. The program should include

inspection of air supply lines, air line pressure, proper lubrication and repair of tools. Refer to ANSI B186.1 for additional maintenance information.

•

Use only genuine Dynabrade replacement parts to insure quality. To order replacement parts, specify

Model#

,

Serial#

and

RPM

of your air tool.

•

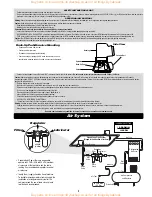

It is strongly recommended that all Dynabrade rotary vane air tools be used with a Filter-Regulator-Lubricator to minimize the possibility of misuse due

to unclean air, wet air or insufficient lubrication. Dynabrade recommends the following:

10681

Air Line Filter-Regulator-Lubricator — Provides accurate air

pressure regulation, two-stage filtration of water contaminants and micro-mist lubrication of pneumatic components.

•

Dynabrade recommends one drop of air lube per minute for each 20 SCFM (example: if the tool specification states 40 SCFM, set the drip rate on the

filter-lubricator to 2 drops per minute). Dynabrade Air Lube (P/N

95842

: 1 pt 473 ml) is recommended.

Routine Preventative Maintenance:

•

Check free speed of tool regularly using a tachometer and after repair and maintenance. Remove abrasive and back-up pad before testing.

•

Inspect back-up pad regularly for nicks, cuts, sharp edges, flatness and runout. Replace damaged or worn back-up pad with genuine

Dynabrade back-up pad.

•

Inspect shroud for wear or damage. Shrouds that are severely worn or subject to a disc breakage must be replaced.

•

Inspect accessories before mounting. Do not mount accessories that are damaged or cracked.

•

Check accessory - speed rating. Rating on accessory must be greater than the tool speed marked on the housing.

•

If accessory breakage occurs, investigate to determine the cause and correct before issuing tool for work.

•

Mineral spirits are recommended when cleaning the tool and parts. Do not clean tool or parts with any solvents or oils containing acids, ester,

ketone, chlorinated hydrocarbons or nitro carbons.

•

DO NOT clean or maintain tools with chemicals that have a low flash point (example: WD-40

®

).

•

A Motor Tune-Up Kit (P/N

96049

) is available which includes high wear and medium wear motor parts.

•

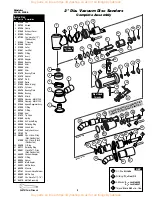

Air tool labels must be kept legible at all times, if not, reorder label(s) and replace. User is responsible for maintaining specification information i.e.:

Model #, S/N, and RPM. (See Assembly Breakdown)

•

Blow air supply hose out prior to initial use.

•

Visually inspect air hoses and fittings for frays, visible damage and signs of deterioration. Replace damaged or worn components.

•

Refer to Dynabrade's Warning/Safety Operating Instructions Tag (Reorder No.

95903

) for safety information.

After maintenance is performed on tool, add a few drops of Dynabrade Air Lube (P/N

95842

) to the air line and start the tool a few times to lubricate air motor.

Check for tool vibration before mounting abrasive wheel accessory.

Handling and Storage:

•

Use of tool rests, hangers and/or balancers is recommended.

•

Protect tool inlet from debris (see Notice below).

•

DO NOT carry tool by air hose or near the tool throttle lever.

•

Protect tool from exposure to water, solvents, high humidity, freezing temperature and extreme temperature changes.

•

DO NOT USE accessories that have been dropped or show signs of cracks, nicks or other defects.

•

Store accessories in protective racks or compartments to prevent damage.

•

Store abrasive discs prior to use at 40-50% relative humidity and 60-80˚F (15-27˚C) to reduce curling.

Machine Specifications

3

Model

Motor

Motor

Sound

Maximum Air Flow

Spindle

Air Pressure

Weight

Length

Height

Number

hp (W)

RPM

Level

SCFM (LPM)

Thread

PSIG (Bars)

Pound (kg)

Inch (mm)

Inch (mm)

51235

.4 (276)

25,000

92 dB(A)

20 (566)

1/4"-20 male

90 (6.2)

1.4 (.6)

9-3/4 (249)

3-7/8 (98)

51236

.4 (276)

25,000

81 dB(A)

20 (566)

1/4"-20 male

90 (6.2)

1.7 (.7)

10-1/4 (261)

3-7/8 (98)

Additional Specifications: Air Inlet Thread 1/4" NPT • Hose I.D. 1/4" (6mm)

Sound Level is the pressure measurement according to the method outlined in ISO regulation ISO-15744.

Warning:

Ear protection to be worn when exposure to sound exceeds the limits of applicable Federal, State or local statutes, ordinances and/or regulations.

Buy parts on line at https://Dynashop.co.uk/ for all things Dynabrade

Buy parts on line at https://Dynashop.co.uk/ for all things Dynabrade