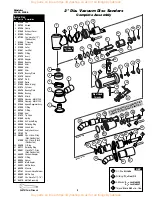

Disassembly/Assembly Instructions - (continued)

Valve Body Assembly:

1.

Insert

01469

Speed Regulator with valve stem and o-rings installed, into housing, secure with

95558

Retaining Ring.

2.

Place seal into housing. Using tweezers or needle nose pliers, place the tip valve into the housing so that the pin goes into the valve stem hole of

regulator assembly.

3.

Place

01468

Spring into housing with small end towards valve assembly.

4.

Assemble muffler assembly. Slip

94523

Inlet Adapter through muffler assembly and secure with

95711

Retaining Ring.

5.

Install air control ring into valve body housing.

6.

Apply #567 Loctite PST Pipe Sealant (or equivalent) to threads of inlet bushing and install muffler assembly onto valve body (torque 23.0 N•m/200 in. lbs.).

7.

Install throttle lever and

12132

Pin. Remove from vise.

Tool Assembly Complete. Please allow 30 minutes for adhesives to cure before operating tool.

Important:

Before operating, place 2-3 drops of Dynabrade Air Lube (P/N

95842

) directly into air inlet with throttle lever depressed. Operate tool for 30 seconds

to determine if tool is operating properly and to allow lubricating oils to properly penetrate motor. Motor should now be tested for proper operation at 90 PSIG. If

motor does not operate properly or operates at a higher RPM than marked on the tool, the tool should be serviced to correct the cause before use.

6

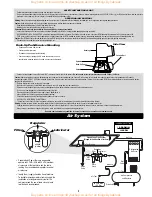

Notice

All Dynabrade motors use the highest quality parts and metals available and are machined to exacting tolerances. The failure of quality pneumatic motors can

most often be traced to an unclean air supply or the lack of lubrication. Air pressure easily forces dirt or water contained in the air supply into motor bearings

causing early failure. It often scores the cylinder walls and the rotor blades resulting in limited efficiency and power. Our warranty obligation is contingent upon

proper use of our tools and cannot apply to equipment which has been subjected to misuse such as unclean air, wet air or a lack of lubrication during the use

of this tool.

Loctite

®

is a registered trademark of Loctite Corp.

Lifetime Warranty

All Dynabrade portable pneumatic power tools are rigorously inspected and performance tested in our factory before shipping to our customers. If a Dynabrade tool

develops a performance problem and an inherent defect is found during normal use and service, Dynabrade will warrant this tool against defects in workmanship and

materials for the lifetime of the tool. Upon examination and review at our factory, Dynabrade shall confirm that the tool qualifies for warranty status, and will repair or

replace the tool at no charge to the customer. Normally wearable parts and products are NOT covered under this warranty. Uncovered items include bearings, contact

wheels, rotor blades, regulators, valve stems, levers, shrouds, guards, O-rings, seals, gaskets and other wearable parts. Dynabrade’s warranty policy is contingent upon

proper use of our tools in accordance with factory recommendations, instructions and safety practices. It shall not apply to equipment that has been subjected to misuse,

negligence, accident or tampering in any way so as to affect its normal performance. To activate lifetime warranty, customer must register each tool at

www.dynabrade.com. Dynabrade will not honor lifetime warranty on unregistered tools. A one-year warranty will be honored on all unregistered portable pneumatic power

tools. Lifetime warranty applies only to portable pneumatic tools manufactured by Dynabrade, Inc. in the USA. Lifetime warranty applies only to the original tool owner;

warranty is non-transferable.

Buy parts on line at https://Dynashop.co.uk/ for all things Dynabrade

Buy parts on line at https://Dynashop.co.uk/ for all things Dynabrade