2

13

14

16

17

18

19

20

21

23

18

24

25

26

2

31

32

33

30

28

29

41

35

36

37

34

4

5

7

12

11

10

9

8

1

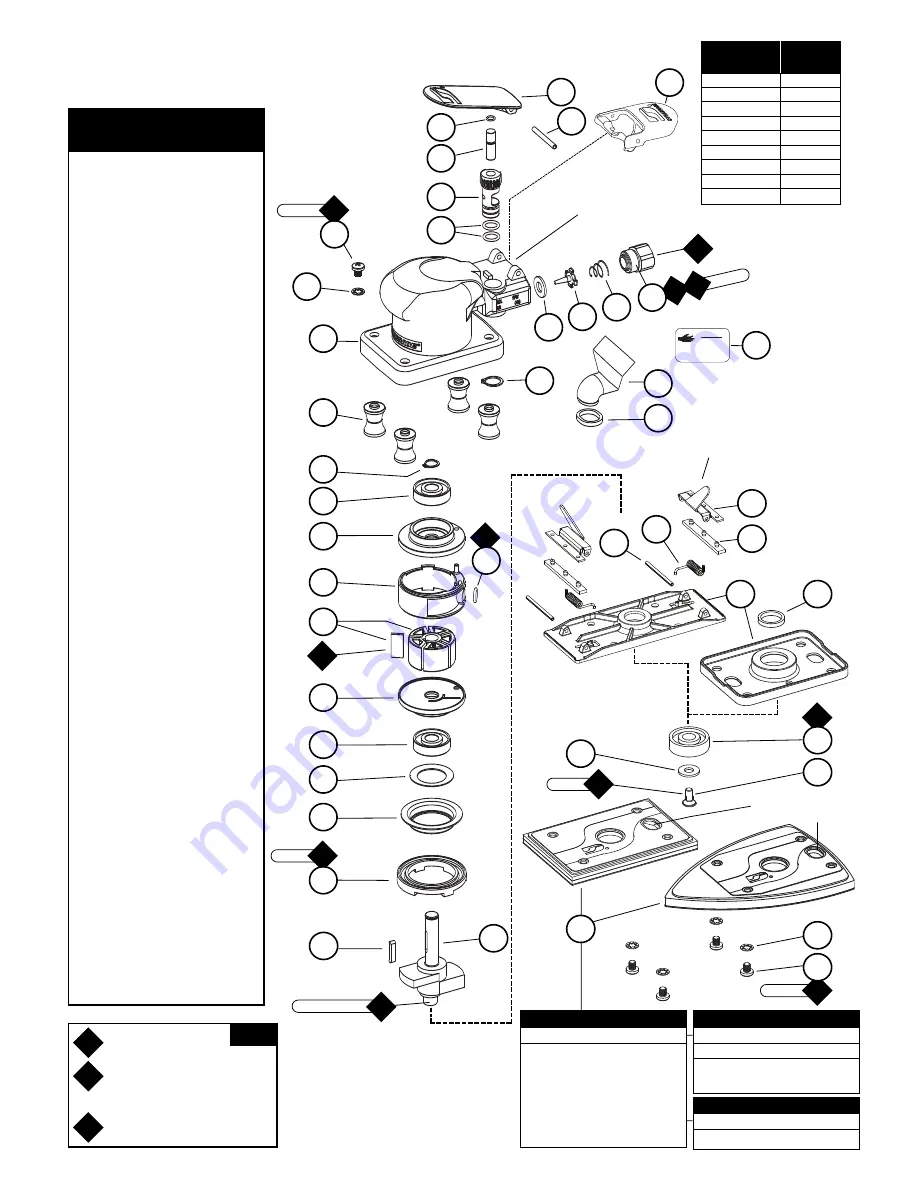

Screw

(4)

96539

Models:

10280-85, 90-92

96080

Model:

10287 Only

2

96538

Lock Washer (8)

3

Pads:

See Chart

4

95344

Screw

5

95935

Washer

6

54552

Bearing

7

57895

Pad Base (Standard)

57875

Pad Base (w/Clips)

8

57896

Felt Seal

9

94590

Pin (2)

10

57899

Spring (2)

11

57834

Rubber Grip (2)

12

57898

Clip (2)

13

Shaft Balancer

57892

Models:

10280-85, 90-91

57894

Model:

10287

14

56047

Key

15

56046

Lock Ring

16

59057

Front Bearing Seal

17

59083

Felt Washer

18

58368

Bearing (2)

19

57893

Front Bearing Plate

20

57113

Blade (5)/Rotor Set

21

59051

Cylinder

(Incl.

01024

O-Ring)

22

01024

O-Ring

23

57891

Rear Bearing Plate

24

98463

Retaining Ring

25

57890

Isolator Post (4)

26

Housing:

See Chart

27

96539

Screw (4)

28

57888

Throttle Lever

29

94590

Pin

30

98459

O-Ring

31

58363

Valve Stem

32

59075

Speed Regulator

33

01025

O-Ring (2)

34

95697

Retaining Ring

35

01464

Seal

36

58365

Tip Valve

37

01468

Spring

38

01494

Inlet Bushing

39

57897

Vacuum Tube

40

96540

Vacuum Port Cover

41

57041

Comfort Platform

Index Key

No. Part # Description

Adhesive:

A

2

= Loctite #271

A

8

= Loctite #567

A

10

= Loctite #243

Torque:

N•m x 8.85 = In. - lbs.

Oil:

O

1

= Air Lube

O

A

T

KEY

40

A

2

O

1

O

1

A

8

O

1

5 N•m

T

17 N•m

T

Internal Threads

2.5 N•m

T

2.5 N•m

T

23 N•m

T

Dynabug

®

II

Complete Assembly

39

8

HOUSING

MODEL

ASSEMBLY #

NUMBER

10220

10280

10221

10281

10222

10282

10223

10283

10225

10285

10227

10287

10230

10290

10231

10291

10232

10292

HOOK SANDING PADS

Model No.

Pad No.

10280 .............. 56315

10281 .............. 56354

10282 .............. 56316

10283 .............. 56317

10285 .............. 56319

10290 .............. 56323

10292 .............. 56326

6

38

15

1

27

22

A

10

Note:

Orientation of

Vacuum Pad.

Note: 57867

Complete

Clipped Pad Base Assembly

available, includes items:

#6, 7, 9, 10, 11 and 12.

Page 8 displays the complete

vacuum configurations.

VINYL SANDING PAD

Model No.

Pad No.

10287 ................ 56354

Note:

For use with clipped pad

base, 68mm x 175mm.

LOOP SANDING PAD

Model No.

Pad No.

10291 ................ 56324

WARNING

DO NOT REMOVE

WARNING

DO NOT REMOVE

Models:

10280

,

10281

,

10282

,

10283

,

10285

,

10287

,

10290

,

10291

,

10292

4

3