All rights reserved. Reproduction or issue to third parties in any form whatsoever is not permitted without written authority from the proprietors.

7

3) Operation and Installation

3.1) General

The general sensor connector configuration is given below;

Cable Code/Pin Configuration:

• Red : V + Power supply v5 to +20 VDC

• Black : Ground Power GND

• X : Yellow : ) Positive, analog output voltage signal for differential mode.

Blue : Signal(-) Negative, analog output voltage signal for differential mode.

WARNING

Never connect the power supply and/or the power ground to yellow and/or blue

cables.

Never connect the power supply to the power ground. Always use a clean power

source and check the voltage range.

4) Sensor Static Calibration Verification

Using gravity, voltage values are measured in the + and – gravity directions, providing a value

of ±1 g. The measurement should be made as follows;

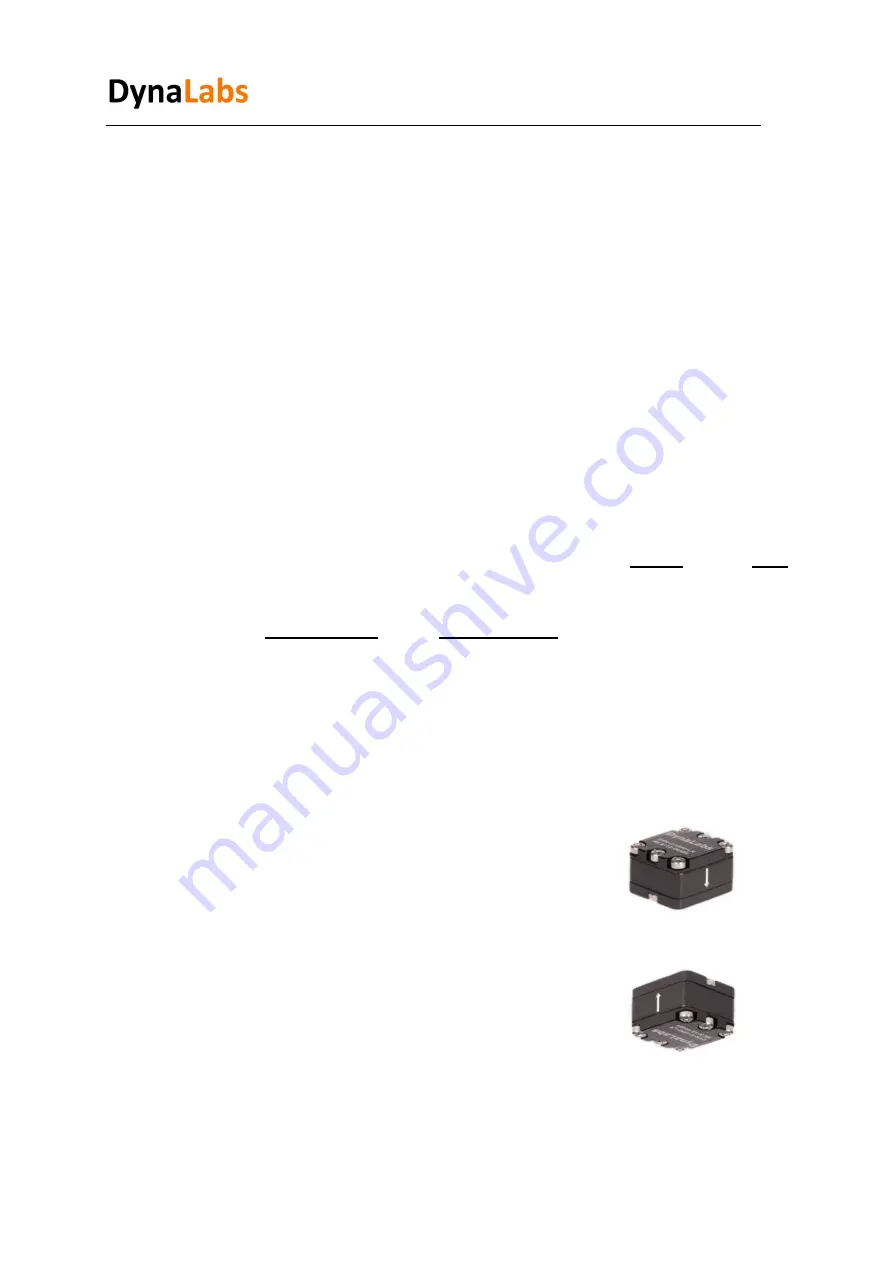

When the sensitivity value of 1000LN series sensors is used

with the data acquisition system, the sensor shows +1 g

with the effect of gravity

in the direction of the arrow sign.

When the sensor is in the opposite direction of the arrow,

it shows -1 g with the effect of gravity.

Using gravity, the voltage values that provide 1 g in the + and - directions are measured and

compared with the catalog value. The calibration value should be close to the catalog value with

10% tolerance. Sensor catalog sensitivity values are given in Table 1.