Operating Instructions SWTD-1000

DYNALCO

7

//

4.

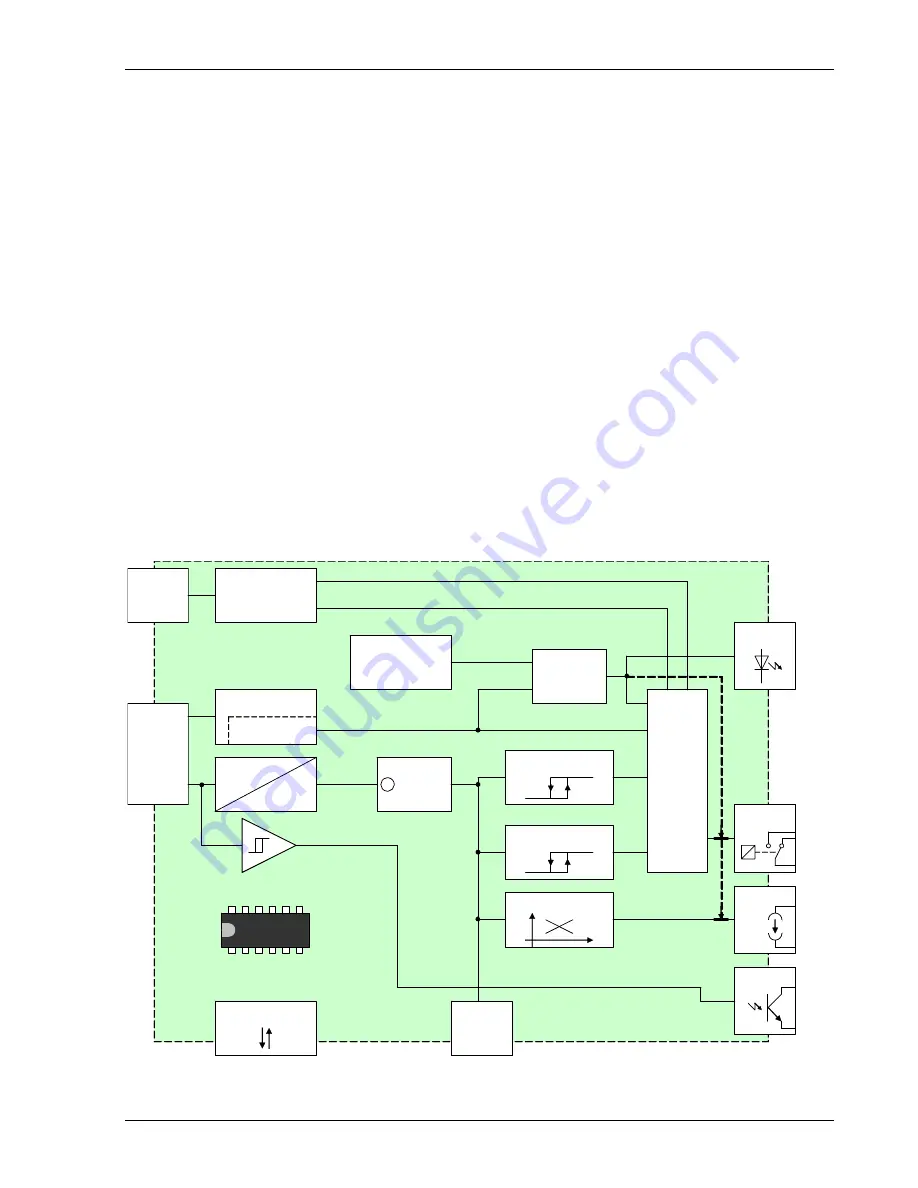

Principle of Operation

4.1 General

The SWTD-1000 is controlled by a microprocessor. It works according to the period measurement

principle whereby the input period is measured with subsequent computing of the reciprocal value

corresponding to the frequency or speed. The relationship between frequency and speed is established

with the Machine factor.

The current output and relay control are determined from the speed.

The relay function is defined via 2 selectable parameter sets. Each parameter set can access the 2 limit

values, the alarm definition, sensor monitoring and other process values.

The 2 limits each have and upper and lower set point (hysteresis setting)

The selection of the valid parameter set is via the binary input.

The relay status may be held until reset via the binary input

The system continuously monitors itself. In addition the sensor may be monitored. Dependent upon the

configuration, these conditions can influence the relay and current output.

The alarm status is indicated via the front panel LED.

The frequency output (open collector output) is not influenced by the machine factor and corresponds to

the input signal frequency.

The input of all parameters is via PC software and the RS232 interface. This may also be used to

interrogate the unit’s settings, measurement and general status.

Parameters are retained in an EEPROM.

Sensor supply

Sensor control

Periodic time

measurement

Frequency

calculation

Machine

factor

X

Definition limit 1

Definition limit 2

Definition current output

Definition

Relay

Analysis of the

binary input

Reset

Choice of the parameter set A/B

Sensor failure

Frequency

Speed

System failure

System control

Definition Alarm

LED

Relay

Current

output

Open

Collector

Sensor

connection

binary

input

RS 232

EEPROM

Display