Page 1

3002xTJ32 MANUAL - FORM 3002TJ-003

MODEL 3002xTJ32

ELECTROMAGNETIC LOCK

INSTALLATION INSTRUCTIONS

02/07

705 Emmett Street Bristol, CT 06010

1-877-DynaLock www.dynalock.com

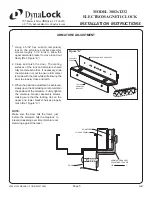

Familiarize yourself with the door and frame conditions. The lock must mount rigidly to the face of the door frame

header. The door mounted armature is supplied with an adjustable mounting bracket and hardware that allows it

to pivot slightly to compensate for reasonable misalignment.

NOTE: If this lock is supplied with the DSM option be certain that disc magnets are present inside the

armature housing.

Care must be taken that the lock face and armature face are kept free of dirt, rust, paint, or any other obstruction

which may interfere with the lock and armature making good contact. These faces may be cleaned with a non-

abrasive pad and wiped with an oil dampened cloth.

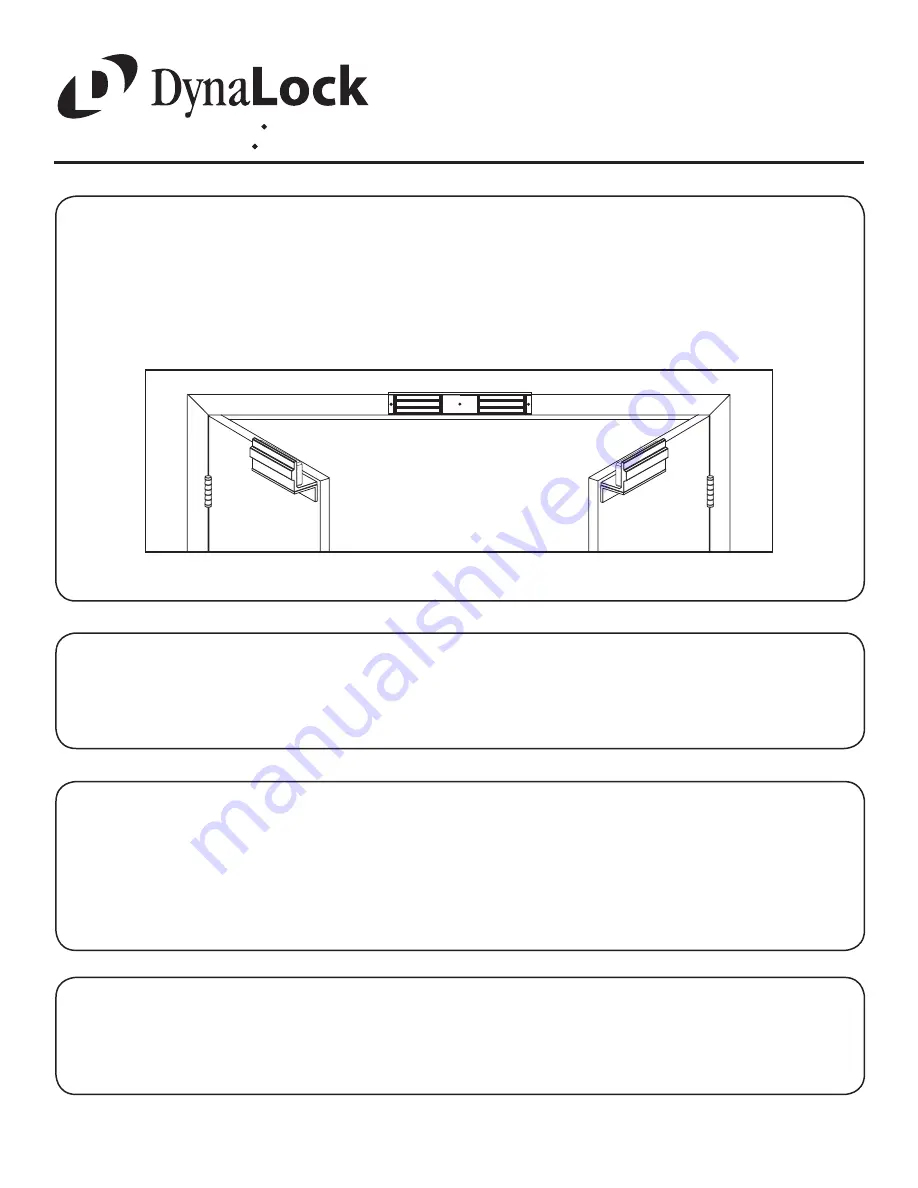

The Series 3002xTJ32 is a 1500 pound holding force top jamb mounted electromagnetic lock designed to secure a

double inswing door. The lock requires both installation procedures as described herein and in the separate wiring

instructions included.

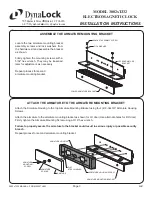

Typical installation of the lock on a double inswing door:

HANDLING

MECHANICAL INSTALLATION

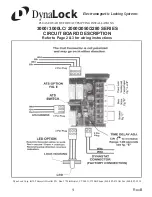

ELECTRICAL INSTALLATION

After mechanical installation is complete the lock needs to be wired to a 12 or 24 VDC/VAC power source. Once low

voltage power is supplied the unit is fully operational. All other wiring is for selected options. Refer to the separate

wiring instructions included for further information.

INSTALLATION DESCRIPTION