9.1 Changing the tamper foot plate

Only use genuine spare parts when changing the

tamper foot plate to a different width.

Protective equipment:

n

Protective gloves

n

Working clothes

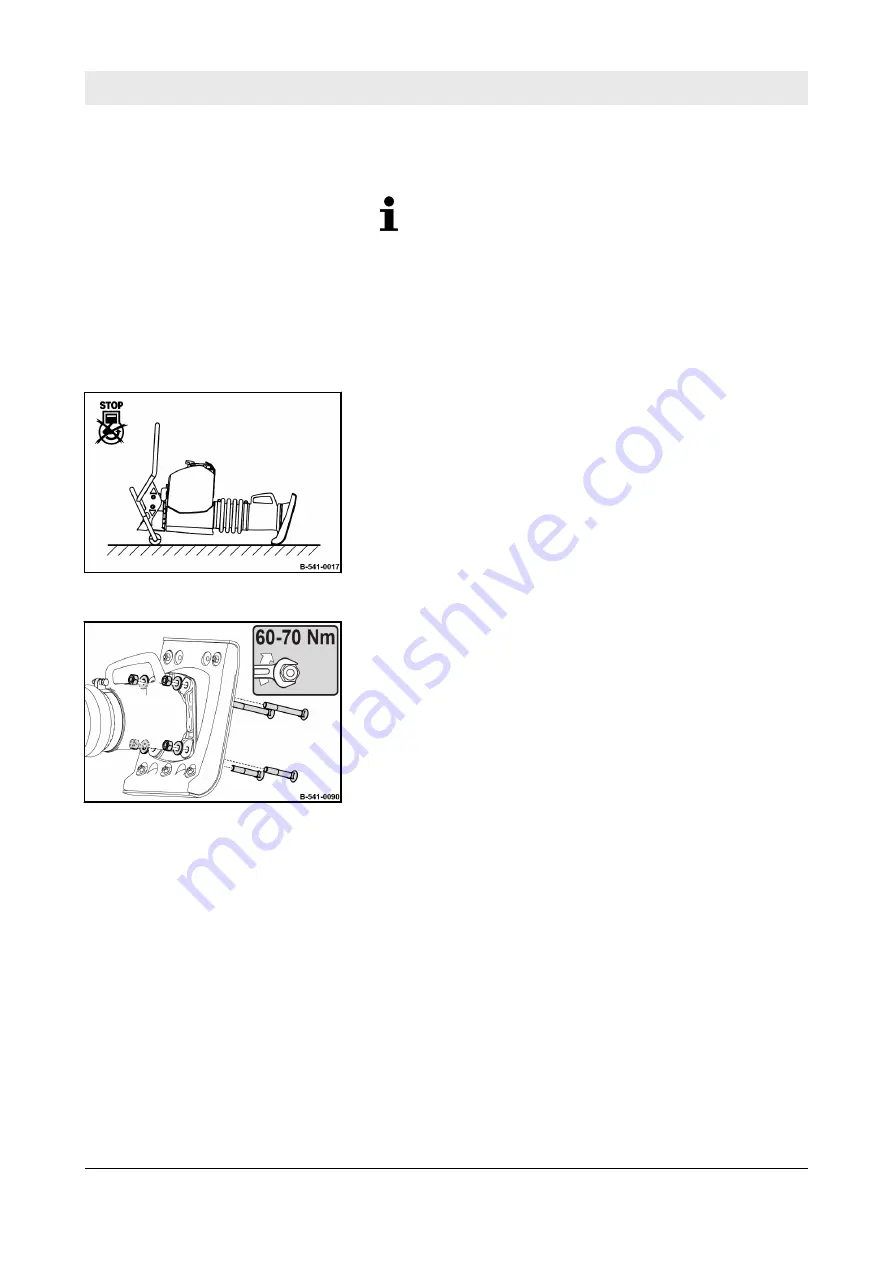

1.

Park the machine in secured condition

„Parking the machine in secured condition“ on page 55

.

2.

Allow the machine to cool down.

3.

Lay the machine carefully on the rollers.

4.

Unscrew the fastening screws.

5.

Take off the tamper foot plate and lay the tamper foot on the

floor.

6.

Fasten the new tamper foot plate with the fastening screws,

tightening torque: 60 bis 70 Nm (44 bis 52 ft·lbf).

7.

Check the engine speed, readjust if necessary

8.9.6 „Checking, adjusting the engine speed“ on page 89

Fig. 118

Fig. 119

Setting up / refitting – Changing the tamper foot plate

DR7X

100

Summary of Contents for DR7X

Page 2: ...2...

Page 6: ...Table of contents DR7X 6...

Page 7: ...1 Introduction Introduction DR7X 7...

Page 11: ...2 Technical data Technical data DR7X 11...

Page 15: ...3 Concerning your safety Concerning your safety DR7X 15...

Page 38: ...Concerning your safety Signage DR7X 38...

Page 39: ...4 Indicators and control elements Indicators and control elements DR7X 39...

Page 41: ...5 Checks prior to start up Checks prior to start up DR7X 41...

Page 47: ...6 Operation Operation DR7X 47...

Page 58: ...Operation Operating hour meter engine rpm meter DR7X 58...

Page 59: ...7 Loading transporting the machine Loading transporting the machine DR7X 59...

Page 63: ...8 Maintenance Maintenance DR7X 63...

Page 98: ...Maintenance As required DR7X 98...

Page 99: ...9 Setting up refitting Setting up refitting DR7X 99...

Page 101: ...10 Troubleshooting Troubleshooting DR7X 101...

Page 108: ...Troubleshooting What to do if the engine has flooded DR7X 108...

Page 109: ...11 Disposal Disposal DR7X 109...

Page 111: ...12 List of special tools List of special tools DR7X 111...

Page 112: ...16 mm spark plug spanner Fig 16 mm spark plug spanner example List of special tools DR7X 112...

Page 113: ......

Page 114: ......