3.6 Start-up procedure

3.6.1 Prior to starting up

Use only machines which are serviced at regular intervals.

Become acquainted with the equipment, the indicators and control

elements, the working principle of the machine and the working

area.

Use your personal protective equipment (hard hat, safety boots, if

necessary also goggles and ear protection).

Do not take any loose objects with you or fasten them to the

machine.

Before start up, check whether:

n

persons or obstructions are beside or in front of the machine,

n

the machine is free of oily and combustible materials,

n

all safety elements are in place,

n

all grips are free of grease, oils, fuel, dirt, snow and ice.

Before start up, carry out all required visual inspections and func-

tion tests.

If the following tests reveal damages or other faults, the machine

must not be operated, until these deficiencies have been corrected.

Do not operate the machine with defective indicators and control

elements.

3.6.2 Starting the engine

Do not use any starting aids like start pilot or ether.

The machine must not be operated with damaged, missing or non-

functional safety installations.

Before starting and moving the machine make sure that there are

no persons inside the danger zone.

Keep your feet clear of the tamper foot plate.

Always keep an eye on the machine when the engine is running

and hold it by the steering bow.

Do not inhale exhaust fumes, because they contain toxic sub-

stances, which could cause damage to health, unconsciousness or

even death.

Avoid operation in closed or partly closed rooms, or ensure ade-

quate ventilation when working in trenches.

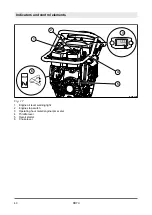

Concerning your safety – Start-up procedure

DR7X

28

Summary of Contents for DR7X

Page 2: ...2...

Page 6: ...Table of contents DR7X 6...

Page 7: ...1 Introduction Introduction DR7X 7...

Page 11: ...2 Technical data Technical data DR7X 11...

Page 15: ...3 Concerning your safety Concerning your safety DR7X 15...

Page 38: ...Concerning your safety Signage DR7X 38...

Page 39: ...4 Indicators and control elements Indicators and control elements DR7X 39...

Page 41: ...5 Checks prior to start up Checks prior to start up DR7X 41...

Page 47: ...6 Operation Operation DR7X 47...

Page 58: ...Operation Operating hour meter engine rpm meter DR7X 58...

Page 59: ...7 Loading transporting the machine Loading transporting the machine DR7X 59...

Page 63: ...8 Maintenance Maintenance DR7X 63...

Page 98: ...Maintenance As required DR7X 98...

Page 99: ...9 Setting up refitting Setting up refitting DR7X 99...

Page 101: ...10 Troubleshooting Troubleshooting DR7X 101...

Page 108: ...Troubleshooting What to do if the engine has flooded DR7X 108...

Page 109: ...11 Disposal Disposal DR7X 109...

Page 111: ...12 List of special tools List of special tools DR7X 111...

Page 112: ...16 mm spark plug spanner Fig 16 mm spark plug spanner example List of special tools DR7X 112...

Page 113: ......

Page 114: ......