2.

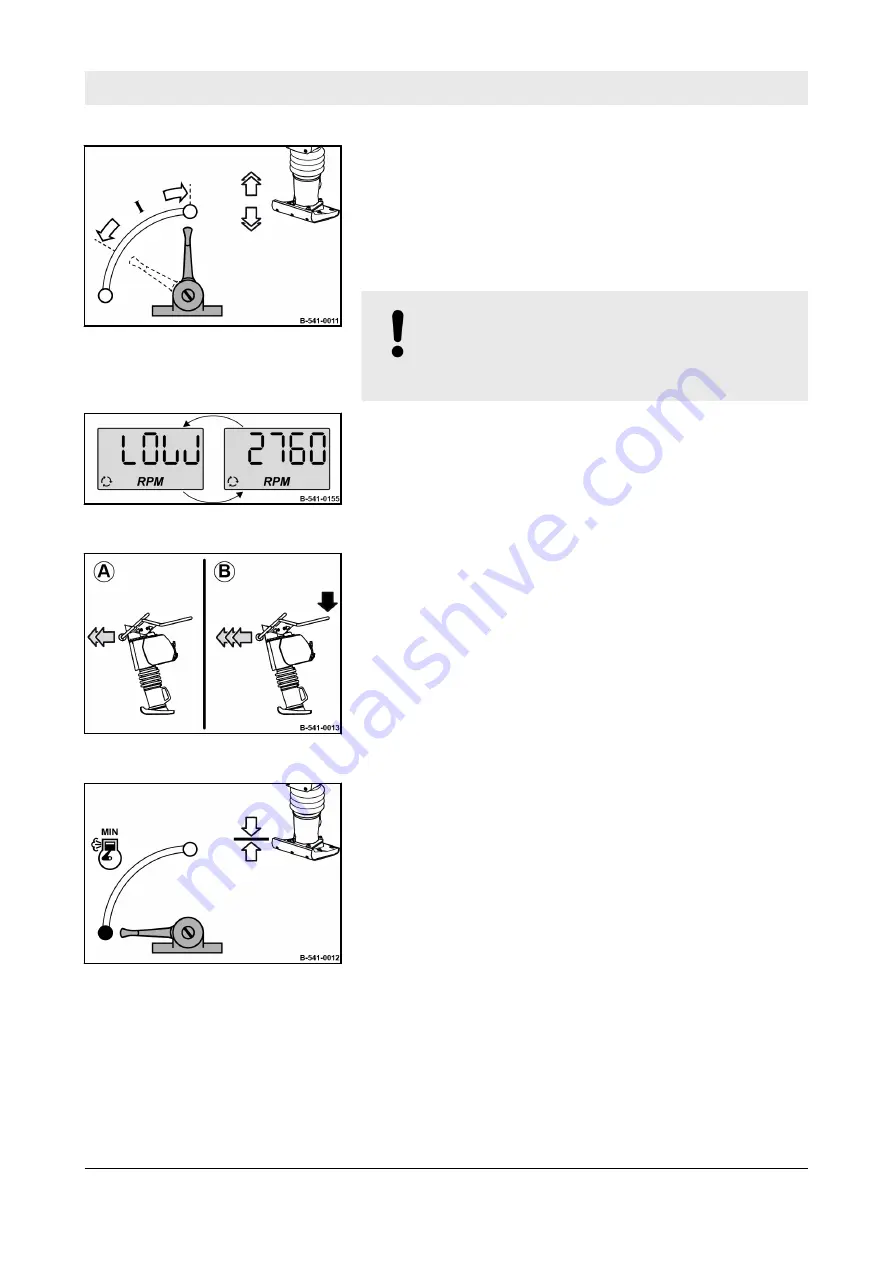

To achieve uniform running you should actuate the throttle

lever within the working range (I), depending on condition

and density of the soil.

ð

Working range (I) = 3600 to 4200 min

-1

3.

If the machine jumps out of rhythm on heavily compacted

soil, you may need to slightly change the engine speed

and/or inclination of the tamper.

NOTICE!

The centrifugal clutch may be damaged!

–

Do not work with engine speeds which are

below the working range.

4.

If the display

[LOW]

appears, increase the engine speed.

5.

Adapt the marching speed by applying load to the guide

handle:

(A) No load

- slowly forward

(B) Heavy load - fast forward

6.

Always shift the throttle lever to position “MIN” for short work

breaks.

Fig. 31

Fig. 32

Fig. 33

Fig. 34

Operation – Operation

DR7X

54

Summary of Contents for DR7X

Page 2: ...2...

Page 6: ...Table of contents DR7X 6...

Page 7: ...1 Introduction Introduction DR7X 7...

Page 11: ...2 Technical data Technical data DR7X 11...

Page 15: ...3 Concerning your safety Concerning your safety DR7X 15...

Page 38: ...Concerning your safety Signage DR7X 38...

Page 39: ...4 Indicators and control elements Indicators and control elements DR7X 39...

Page 41: ...5 Checks prior to start up Checks prior to start up DR7X 41...

Page 47: ...6 Operation Operation DR7X 47...

Page 58: ...Operation Operating hour meter engine rpm meter DR7X 58...

Page 59: ...7 Loading transporting the machine Loading transporting the machine DR7X 59...

Page 63: ...8 Maintenance Maintenance DR7X 63...

Page 98: ...Maintenance As required DR7X 98...

Page 99: ...9 Setting up refitting Setting up refitting DR7X 99...

Page 101: ...10 Troubleshooting Troubleshooting DR7X 101...

Page 108: ...Troubleshooting What to do if the engine has flooded DR7X 108...

Page 109: ...11 Disposal Disposal DR7X 109...

Page 111: ...12 List of special tools List of special tools DR7X 111...

Page 112: ...16 mm spark plug spanner Fig 16 mm spark plug spanner example List of special tools DR7X 112...

Page 113: ......

Page 114: ......