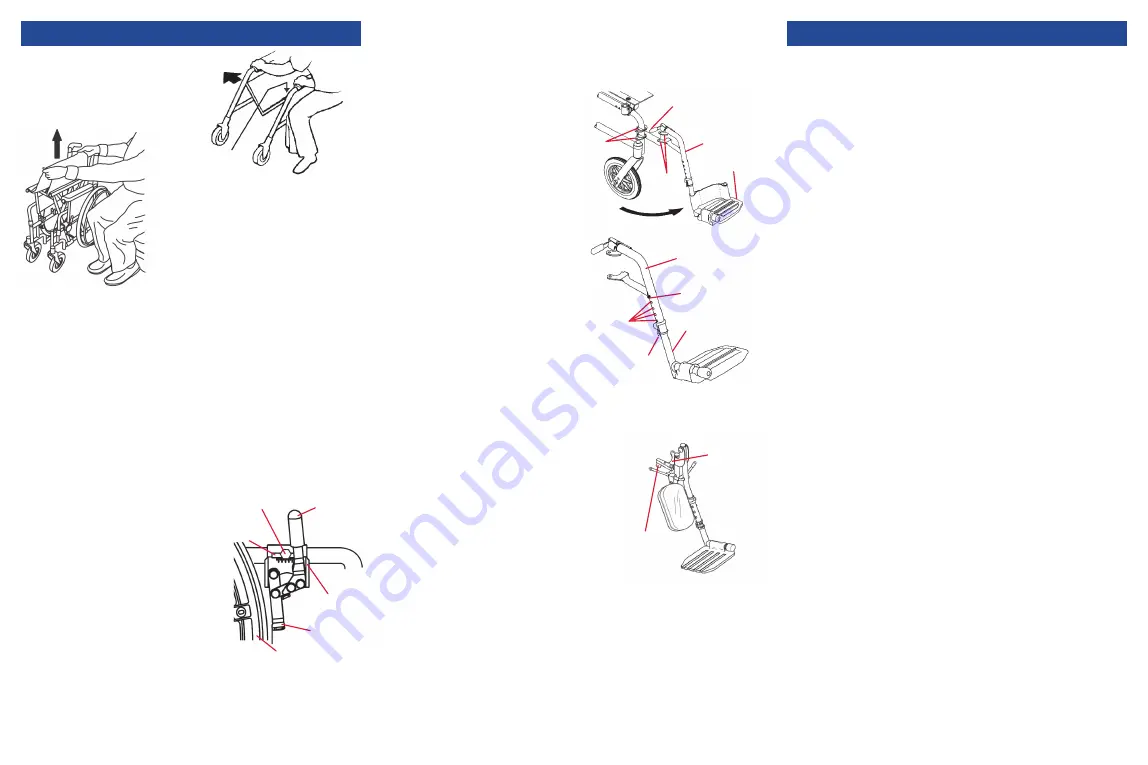

Wheel Lock

Shoe

Handle

Carriage Bolt

and Nut

Mounting

Positions

Rear Wheel

Wheel Lock

Hinge

Plate

Release Lever

Front Rigging

Release Lever

Front Rigging

Assembly

Footplate

Hinge

Plates

Hinge

Pins

Front Rigging

Support

Release

Button

Footplate

Assembly

Cam Lock

Lever

Adjustment

Holes

USE AND SAFETY

WARNING

TO OPEN CHAIR

Open wheelchair by tilting to

one side and pushing down on

seat rail until fully opened.

TO CLOSE CHAIR

First fold foot plates to vertical

position. Grab seat with both

hands at front and back edge and

lift. Or, tilt chair to one side and lift

up on seat rail.

BACK WHEELS

Large rear wheels should be inspected

at least once a month to ensure proper tightness. If wheel

wobbles or is loose, release lock nut and tighten axle bolt

slightly. Test for proper tightness by leaning chair to one

side and spin adjusted wheel.

TIRES

Solid rubber tires need minimal maintenance, but

should be cleaned occasionally with a damp cloth. Replace

if tires become severely worn or cracking appears.

WHEEL LOCKS

Engage both wheel locks before getting

in or out of chair, leaning forward in chair, or while in an

elevator or wheelchair lift. Locks

are engaged by pushing handle

completely forward. Adjustments

to locks are made by loosening

or tightening nut on the carriage

bolt. Wheel lock shoe should be

embedded at least ⅛″. Adjust by

sliding clamp toward rear wheel

while handle is engaged in

locked position. Tighten nut and

bolt to secure in position. Test for

correct locking action before

actual use.

FRONT CASTERS

Casters should be checked periodically

and lubricated occasionally. Lubricate by removing fork and

greasing caster stem bearings and wheel bearings.

Do not adjust or operate wheelchair without carefully

reading all instructions in this manual.

Do not operate this wheelchair on roadways, streets or any

surfaces with vehicular traffic.

Do not operate on inclines without proper assistance.

When getting in and out of wheelchair or when in elevator or

wheelchair lift, wheel locks must be fully engaged.

Wheelchair should be on a smooth, stable and level area

with wheel locks engaged before transferring user in or out

of wheelchair.

Footrest should not be lower than 2½″ from the ground to

ensure clearance.

Do not stand on or apply weight to foot rests.

Rotate casters to front of the wheelchair and engage wheel

locks to help prevent wheelchair from tipping over before

reaching or leaning forward.

When trying to extend arms over back, only reach as far as

your arm can extend without having to alter your seating

position. Do not lean over or apply weight to the top of

wheelchair back. This can cause wheelchair to tip over.

DO NOT stand on wheelchair.

Reassemble fork and wheel by tightening nuts until no play

remains, but wheels roll freely. If nut is too loose, caster will

shimmy, if too tight, chair will be hard to steer.

REMOVAL OF SWING-AWAY

FOOTRESTS/LEG RESTS

Release lock by pushing on

the front rigging lever.

Swing-away foot rest/leg

rest out and sideways.

Lift to remove.

ADJUSTING LENGTH OF

FOOTREST/LEG REST

When adjusting length of

footrests or leg rests, user

should be sitting in wheelchair

with feet on the foot plates.

Loosen cam lock lever around

support assembly and push the

release button. Raise or lower

foot plate to desired position that

will provide maximum support of

thighs. Ensure release button is

fully engaged, tighten cam lock lever. Front rigging should

not be so low that it causes uncomfortable pressure to

thighs at front of seat upholstery.

ADJUSTING/ELEVATING LEG REST

Lift foot plate on leg rest assembly

to desired position. Release leg rest

assembly and it will automatically

lock into place. To lower, push the

release lever and lower foot plate

to desired position.

GENERAL CARE

Wipe chrome parts with a clean, soft

cloth at least once a week. All metal parts can be cleaned

with auto wax or similar products. If exposed to moisture,

dry immediately. Do not use an abrasive cleanser that will

scratch the finish.

REMOVABLE ARMS

Remove arms by depressing spring

button and lifting arms out of front and rear sockets.

Reorder

Nos. 10242

10243

10244