16

Dynaset Oy | Menotie 3, FI-33470 Ylöjärvi, Finland | tel: +358 3 3488 200 | info@dynaset.com | www.dynaset.com

HYDRAULIC SCREW COMPRESSORS

OPERATING PRINCIPLES

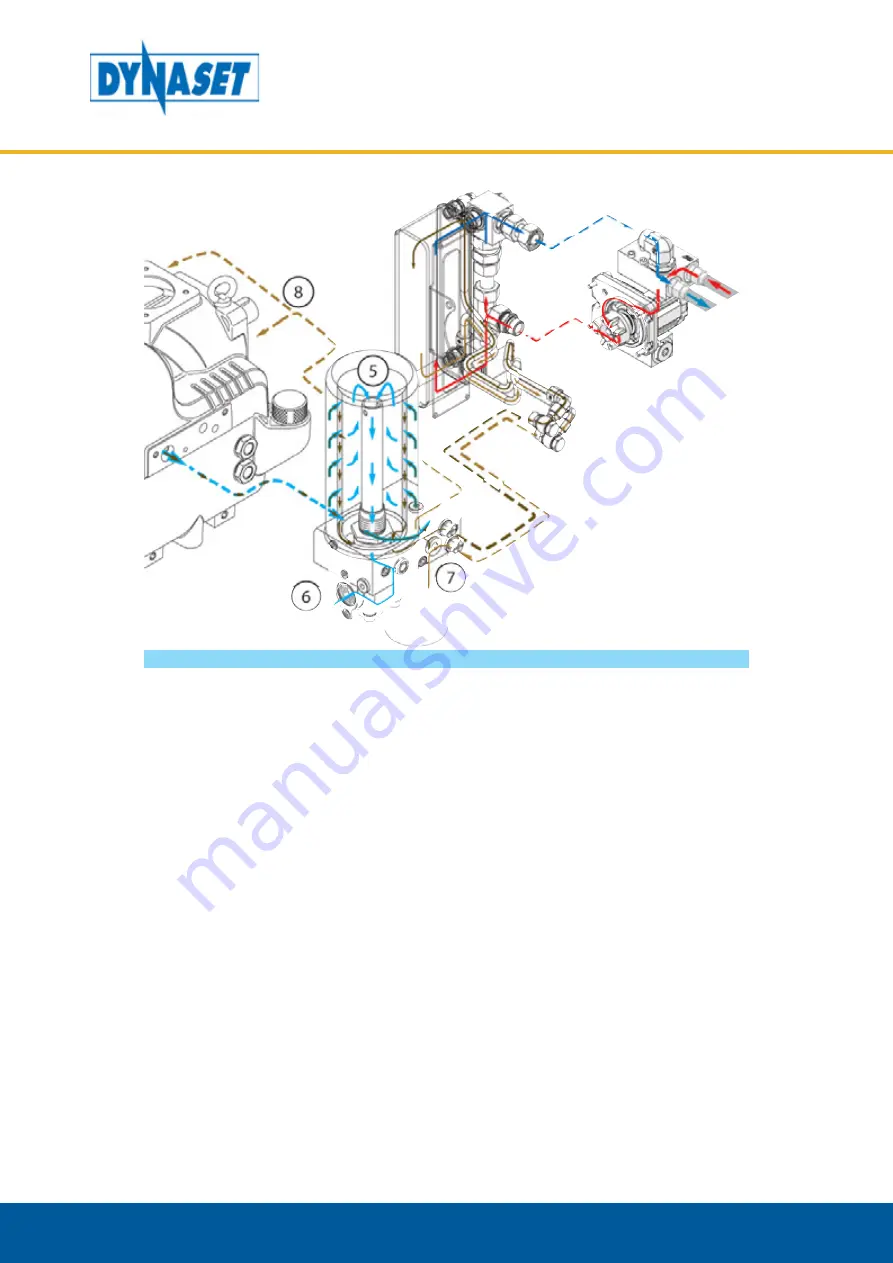

Picture 6: Operating description: Air output, oil filtering and cooling

5. The air-oil mixiture flows to the air-oil separating element where the oil is

filtered out down to a residual content of < 3 mg/m

3

.

6. Compressed and filtered air continues from air-oil separating element to the air

supply system through minimum pressure valve and AP-port.

7. Depending on the oil temperature, the oil thermostat valve routes the oil

flow through the oil cooler or directly to the oil filter. Optimum operating

temperature of oil is adjusted by integrated thermostat valve.

8. The oil flows from the oil filter to various injection points in the compressor

block.

When air supply line is closed and preset air pressure is reached, compressor starts

to run automatically in off-load mode. Pneumatically controlled intake valve is

closed and compressor’s internal pressure drops to 5.5 bar. Pressure in supply line

remains until supply line is opened.

When the compressed air in air supply line is needed, off-load automatic controls

the intake valve according to the current air demand.

Summary of Contents for HKR 1300

Page 2: ......

Page 75: ...DYNASET OY all rights reserved...