48

Dynaset Oy | Menotie 3, FI-33470 Ylöjärvi, Finland | tel: +358 3 3488 200 | info@dynaset.com | www.dynaset.com

HYDRAULIC SCREW COMPRESSORS

MAINTENANCE

6.3.1. MULTI-GRADE OIL

ATTENTION!

The use of multi-grade oils can cause problems in the long run since

viscosity improvers of oil are destroyed over time.

The oil is then no longer secured in the upper viscosity class and a thermal stability

is no longer completely ensured. Therefore, the use of multi-grade oils in DYNASET

HKR compressors is not authorized.

• Only use oils approved for screw compressors!

• Use the same manufacturer and the same oil type as is currently in use in the HKR

screw compressor.

NOTE

!

Mixing different oils is not permissible.

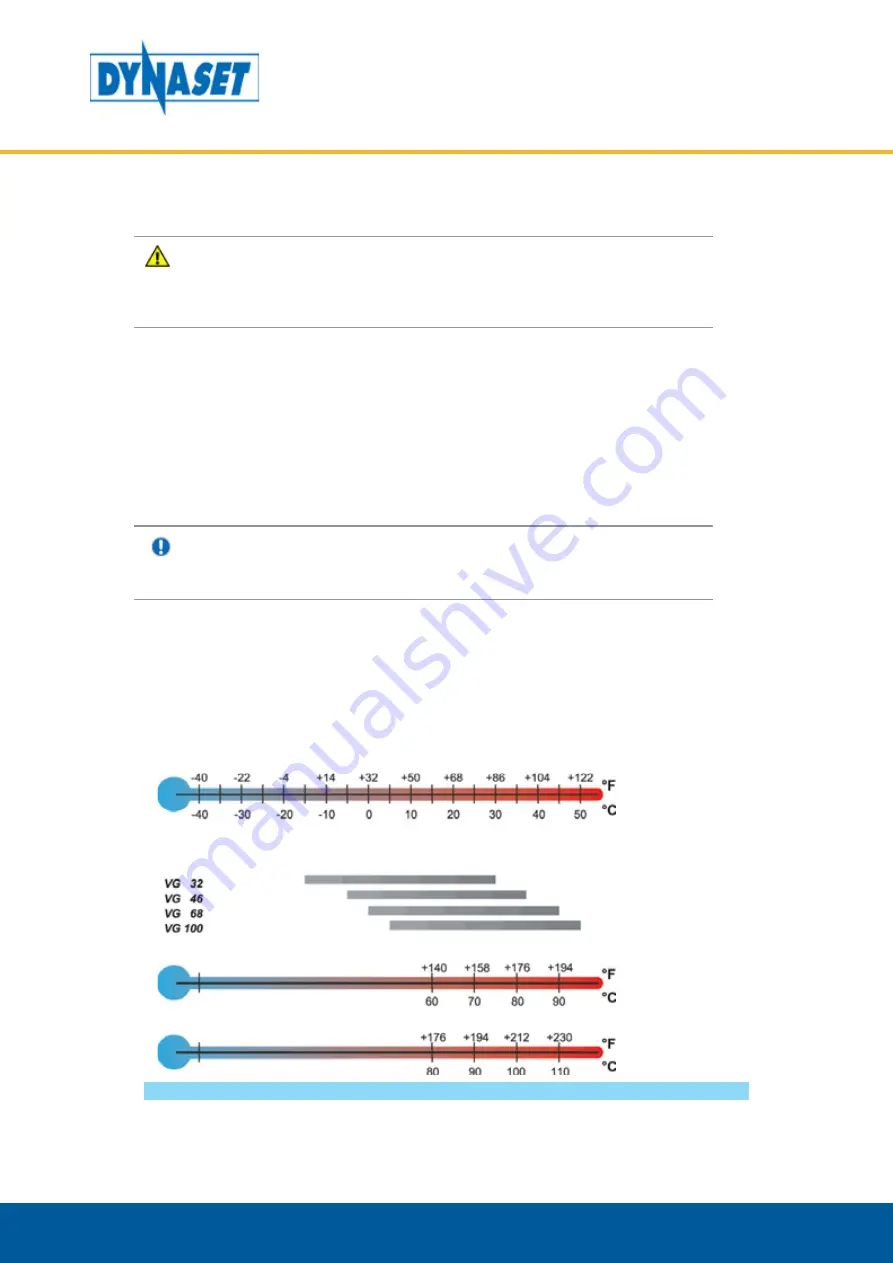

6.3.2. TEMPERATURES AND OIL TYPES

Ambient temperature of the compressor

Classes of oil for compressors

Compressor oil injection temperature

Compressor outlet temperature

Picture 42: Temperatures and oil types

Summary of Contents for HKR 1300

Page 2: ......

Page 75: ...DYNASET OY all rights reserved...