5.25”

Green engine

block ring

Green engine block

ring inside tube

Place centering rings

between the marks

on the tube

Apply a line of glue around

the tube here

Step 5

Align the holes when

glueing together

Make sure to remove these

square pieces with a

hobby knife first

Inside of tube

Booster tube

Place glue on the inside

edge of tube here

Step 7

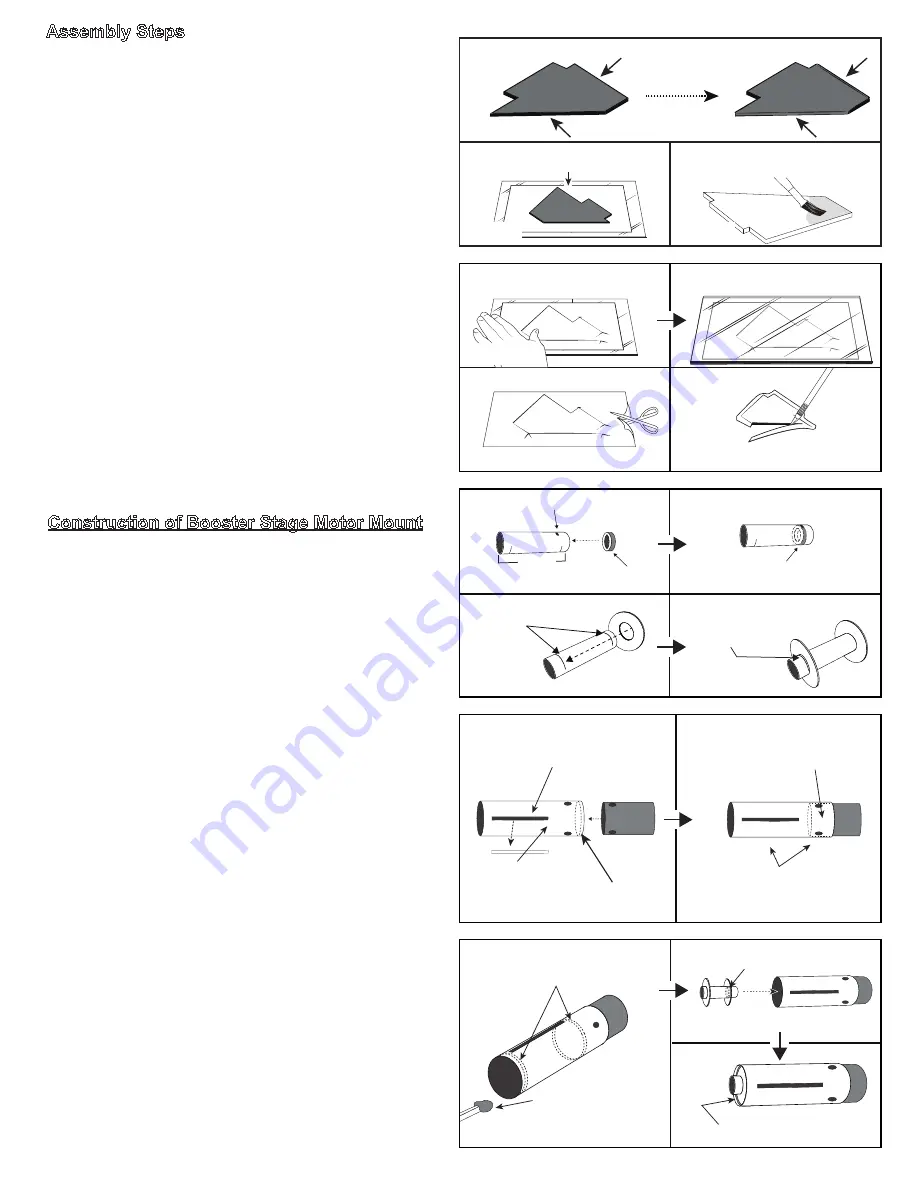

Assembly Steps

Construction of Booster Stage Motor Mount

1.

(Optional to reduce drag)

Sand the balsa laser-cut

sheets using 200 grit sandpaper. Then remove the fins

with a hobby knife and airfoil the front and rear edges.

2.

(Optional for Fin Skins)

Fin skins are highly rec-

ommended to survive a hard landing.

Place a piece

of regular paper on top of a smooth surface (wood or

glass). Then place a fin on top of the paper.

3.

(Optional Fin Skins)

Mix glue with water in a small

cup (the right mixture should be watery enough to

avoid leaving brush marks when painting the fin). Use

a paintbrush to apply a thin layer of the mixture to one

side of the fin. Once complete, flip over the fin (press

into the paper you placed in the prior step) and paint

the mixture onto the opposite side.

4.

(Optional Fin Skins)

Place a piece of paper over

the top of the fin. Press down on the paper to rub out

any bumps in the paper to smooth out the surface of

the fin. Place wood or glass on top of the paper and

then place some books or weight on top and let dry.

Once dry, cut out the fin from the paper and trim away

the overlap with a hobby knife. Repeat this process for

all 6 fins.

The booster stage is the lowest section of the rock-

et. It is designed to fall off and tumble back to the

ground after the engine burns out during the flight.

5. The

booster stage engine mount tube

is the short-

er 29mm tube that is 5.25in (133mm) long, and it has a

small rectangular cutout at one end of the tube. Locate

one of the green rings (CR 24/29). Using a wood dow-

el, spread a line of glue inside the tube at the cut-out

location. Slide the green ring inside the tube so it is

visible through the cut-out window of the tube. Wipe off

any glue that oozes out with a paper towel

6. Test fit both large wooden CR 29/2.6" centering

rings onto the

motor mount tube

. Sand the inside of

the rings if necessary. Now spread a thin line of glue

around the inside edge of one of the tube line mark-

ings. Then slide one of the rings over the glue and rest

it just behind the tube mark. Repeat step for the other

centering ring. Clean off excess glue and let dry. Set

aside the motor mount for now.

7. Add a ring of glue to the inside forward edge of the

booster tube.

Then

take the

red tube coupler

with

the holes in it and slide it into the

booster tube

. Take

care to align the holes in both tubes. Wipe away any

excess glue on the inside and the outside of the tubes.

8. Use a wood dowel to spread two lines of glue inside

the

booster tube

; one line of glue on each side of the

slots cut in the tube. Now slide the

motor mount

into

the

booster tube

(into the end with no coupler). The

motor mount

will stop against the inside end of the

coupler, clean off any excess glue. Apply a fillet

of glue around the edge of the back ring.

Place a single fin on a large piece

of regular printer paper

Air-foil the fins by rounding out top and bottom edges

with sand paper

Use painbrush to brush on

the glue

Use wood dowel to place a

glue ring at these areas

inside the tube

Insert the end with the engine

block into the booster tube first

Wood dowel with glue

Apply a glue fillet here

Step 8

Smooth the fin under the top

& bottom layers of paper

Glass over the top

When dried, cut out fin

Trim edges of paper off of the

fin with a hobby knife

Page 2

Step 2

Step 4

Step 1

Step 3

Step 6