InsTallaTIon and feaTures

DYNATRON® T3™ HI-LO TREATMENT TABLE & T4™ TRACTION TABLE | OPERATOR’S MANUAL REV. 10 | 4/4/2018

3

Installation

and Features

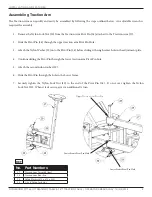

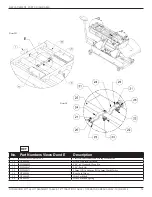

Unpacking

Upon receiving the table, immediately unpack it and verify that all parts and accessories are included. Check for possible

damage, obvious or concealed. In case of damage, immediately notify the freight carrier and take any steps necessary to file a

claim for the damage sustained. If possible, reuse the shipping carton if the table must be shipped for any reason. The carton

is specially designed to protect the table from shipping damage. Improper packaging of the unit during transport can result

in damage and invalidate the warranty.

Complete the warranty registration form located at the back of this manual and return it to Dynatronics within 30 days

of purchase. This is essential to insure you are not billed for services that are covered by the warranty policy. Warranty

registration should include all applicable serial numbers.

Setup

• After unpacking, set the table in the desired location. No assembly is required as the table is fully assembled and all

motors are pre-adjusted at the factory.

• Provide ample clearance around and above the table.

• Securely lock all four casters for stability. Install the traction arm for the T4 table (see instructions on the following

page). Inspect all cables and power cord for damage;

• Immediately report any damage found to Dynatronics’ Customer Service (800) 874-6251.