4

CONFIGURATION AND ADJUSTMENT

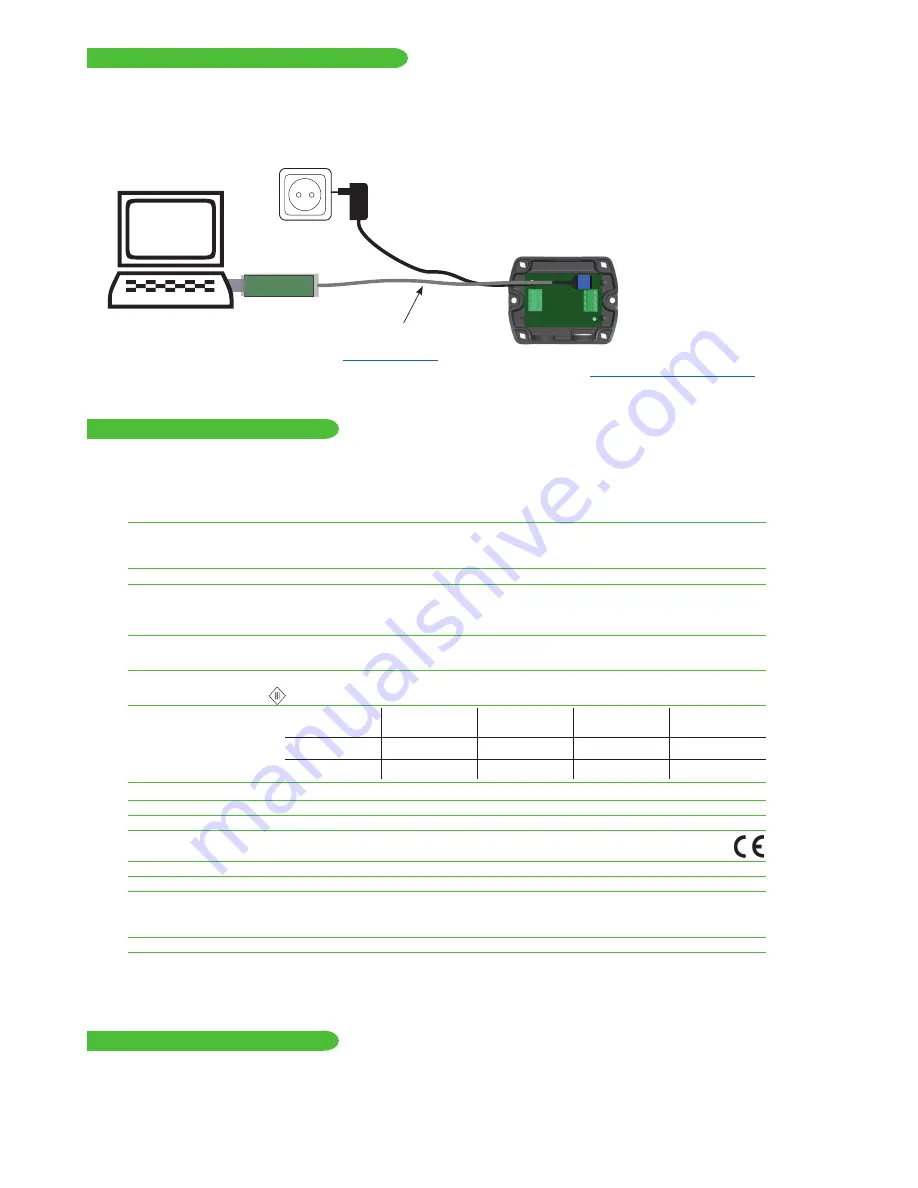

The EE660 as ordered is ready for use immediately and requires no configuration by the user. If required, the optional USB

configuration adapter and the E+E Product Configuration Software (EE-PCS) can be used for changing the factory setup as

well as for adjusting of the air velocity measurement.

Note:

The EE660 must not have any additional power supply when using the

USB configuration adapter

HA011066.

PC

HA011066

For product data sheets EE-PCS please see

www.epluse.com

.

The E+E Product Configuration Software (EE-PCS) is free and can be downloaded from

www.epluse.com/configurator

.

TECHNICAL DATA

(Modification rights reserved)

ACCESSORIES

• USB configuration adapter

HA011066

• Product configuration software

EE-PCS

(free download: www.epluse.com/EE660)

• Power supply adapter

V03

(see data sheet Accessories)

Measurand

Working range

1)

0...1 m/s

(0...200 ft/min)

0...1.5 m/s

(0...300 ft/min)

0...2 m/s

(0...400 ft/min)

Accuracy at 20 °C

2)

(68 °F)

,

0.15...1 m/s

(30...200 ft/min)

± (0.04 m/s

(7.9 ft/min)

+ 2 % of mv)

45 % RH, 1013 hPa

0.15...1.5 m/s

(30...300 ft/min)

± (0.05 m/s

(9.8 ft/min)

+ 2 % of mv)

0.15...2 m/s

(30...400 ft/min)

± (0.06 m/s

(11.8 ft/min)

+ 2 % of mv)

Response time

τ

90

3)

typ. 4 sec or typ. 1 sec (at constant temperature)

Output

Analogue

0 - 10 V

and 4 - 20 mA

0...1 m/s / 0...1.5 m/s / 0...2 m/s

1)

-1 mA < I

L

< 1 mA R

L

< 450

Ω

(linear, 3-wires)

Digital interface

RS485 with max. 32 devices on one bus

Protocol

Modbus RTU or BACnet MS/TP

General

Power supply (Class III)

24 V AC/DC ± 20 %

Current consumption (max.)

AC supply -

no display

DC supply -

no display

AC supply -

with display

DC supply -

with display

Analogue ouput

74 mA rms

41 mA

180 mA rms

85 mA

Digital output

120 mA rms

50 mA

-

-

Angular dependence

< 3% of the measured value at |

∆α

| < 10°

Electrical connection

screw terminals max. 1.5 mm

2

(AWG 16)

Cable gland

M16x1.5

Electromagnetic compatibility

EN61326-1 EN61326-2-3

Industrial Environment

Housing material

Polycarbonate, UL94V-0 (with Display UL94HB) approved

Protection class

Enclosure IP65 / NEMA4, remote probe IP20

Temperature range

working temperature probe

-25 ... +50 °C

(-13...122 °F)

working temperature electronic

-10 ... +50 °C

(14...122 °F)

storage temperature

-30 ... +60 °C

(-22...140 °F)

Working range humidity

5...95 % RH (non-condensing)

1) Selectable by jumper, only for analogue output

2)

The accuracy statement includes the uncertainty of the factory calibration with an enhancement factor k=2 (2-times standard deviation).

The accuracy was calculated in accordance with EA-4/02 and with regard to GUM (Guide to the Expression of Uncertainty in Measurement).

3) Selectable by jumper (analogue) and slide switch (digital)