7

E-flite Fokker DVII 250 Slow Flyer Assembly Manual

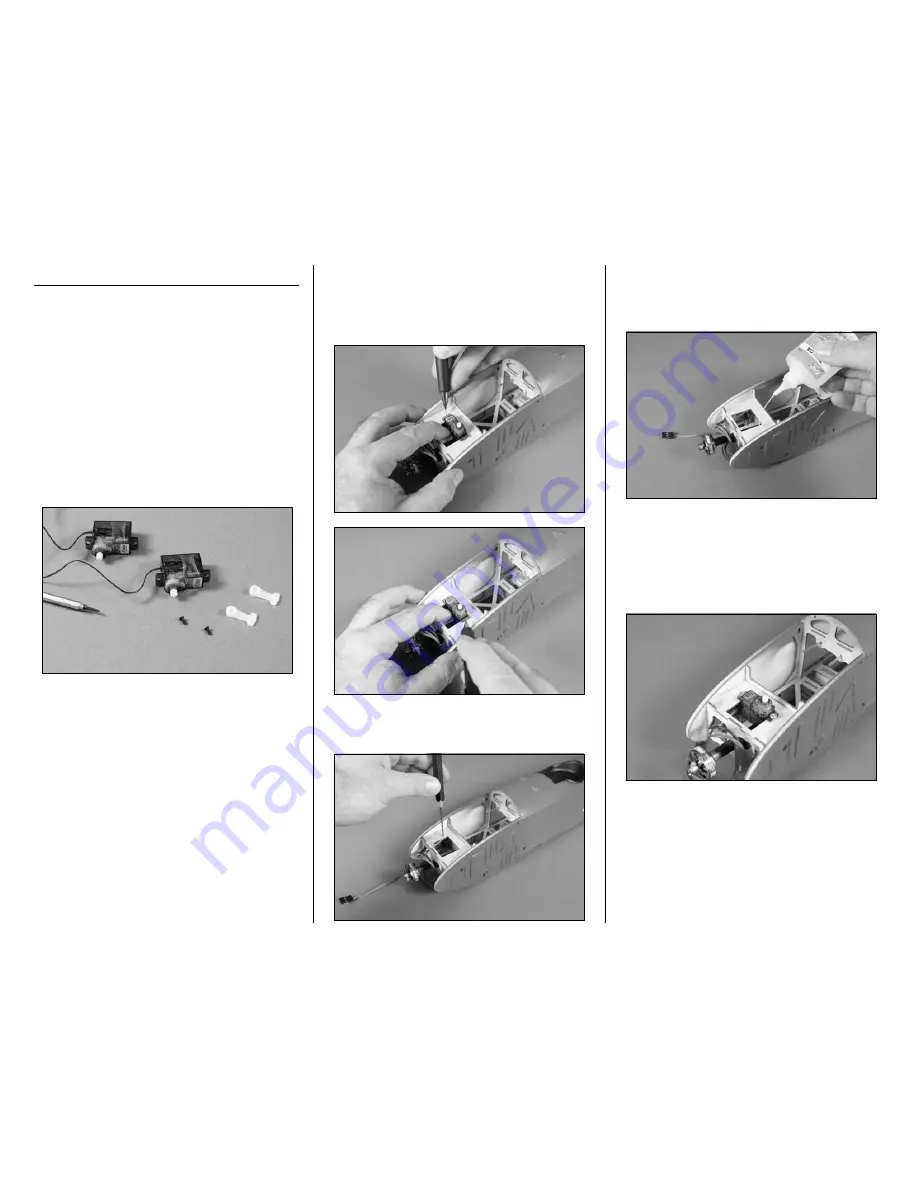

Servo Installation

Required Parts

Fuselage

Servo with hardware (2)

Receiver

Micro pushrod connector (2)

Micro pushrod connector backplate (2)

Required Tools and Adhesives

Pin drill

Thin CA

Pliers

Pencil

Phillips screwdriver: #0, #1

Drill bit: 1/16-inch (1.5mm)

1. Use a #0 Phillips screwdriver to remove the

servo arms from the rudder and elevator servos.

2. Position the rudder servo in the opening at the

front of the fuselage as shown. Slide the servo as

far back in the opening as possible. Use a pencil to

mark the position for the screws that will be used to

secure the rudder servo.

3. Use a pin drill and 1/16-inch (1.5mm) drill bit

to drill the holes for the two servo mounting screws.

4. Apply 2–3 drops of thin CA into each of the

holes to harden the surrounding wood. This is done

to strengthen the wood and provide a stronger

surface for the servo mounting screws.

5. Position the rudder servo back in the opening

in the front of the fuselage. Use a #1 Phillips

screwdriver and the screws provided with the servo

to secure the rudder servo. The lead from the servo

will exit the hole in the bottom of the fuselage as

shown.