5

E-flite Habu 32 EDF ARF Assembly Manual

During the course of building your model we

suggest you use a soft base for the building surface.

Such things as a foam stand, large piece of

bedding foam or a thick bath towel will work well

and help protect the model from damage during

assembly. This is not shown in the instructions

to provide the greatest detail in the photos.

When referencing directions (up, down, left,

right top and bottom) these directions are in

relationship to the pilot sitting in the cockpit

of the aircraft unless noted otherwise.

Control Horn Installation

Required parts

Fuselage

Wing panel (right and left)

Stabilizer (right and left)

Fiberglass control horn (7)

Required Tools and Adhesives

Felt-tipped pen

5-minute epoxy

Mixing stick

Mixing cup

Low-tack tape

Medium grit sandpaper

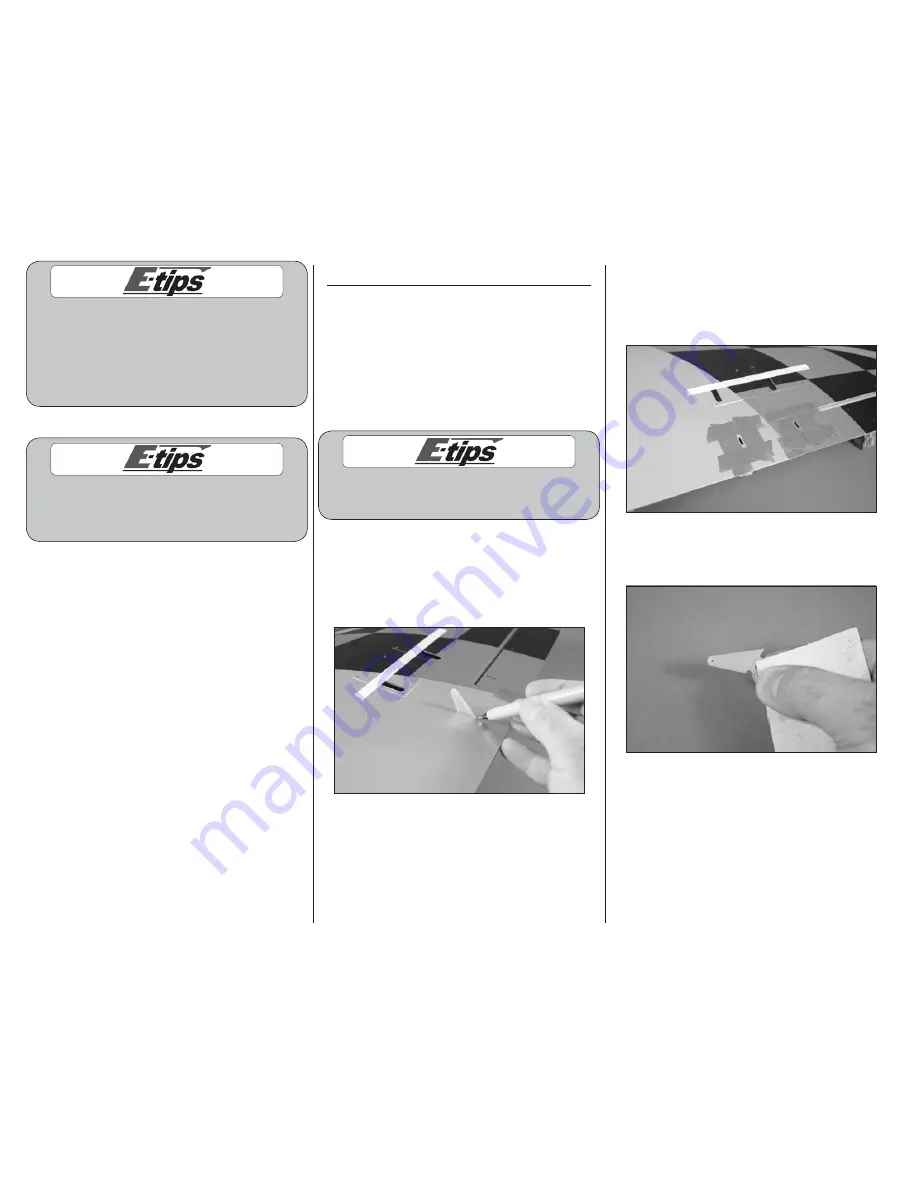

We used low-tack tape to tape the aileron at the

tip and to tape the flap to the aileron so they

don’t move during the control horn installation.

1. Check the fit of the fiberglass control

horn in the slot in the aileron. The hole in the

control horn will align with the hinge line, and the

horn will fit flush in the hole. Use a felt-tipped pen

to mark the front and rear edge of the control horn

on the aileron.

2. Apply low-tack tape around the

opening for the flap and aileron control horn.

Position the tape so it is 1/32-inch (1mm) away

from the sides of the hole, as well as from the

marks made in the previous step.

3. Use medium grit sandpaper to lightly

sand the control horns where they fit into the

openings in the flap and aileron.