18

E-flite Shoestring 15e ARF Assembly Manual

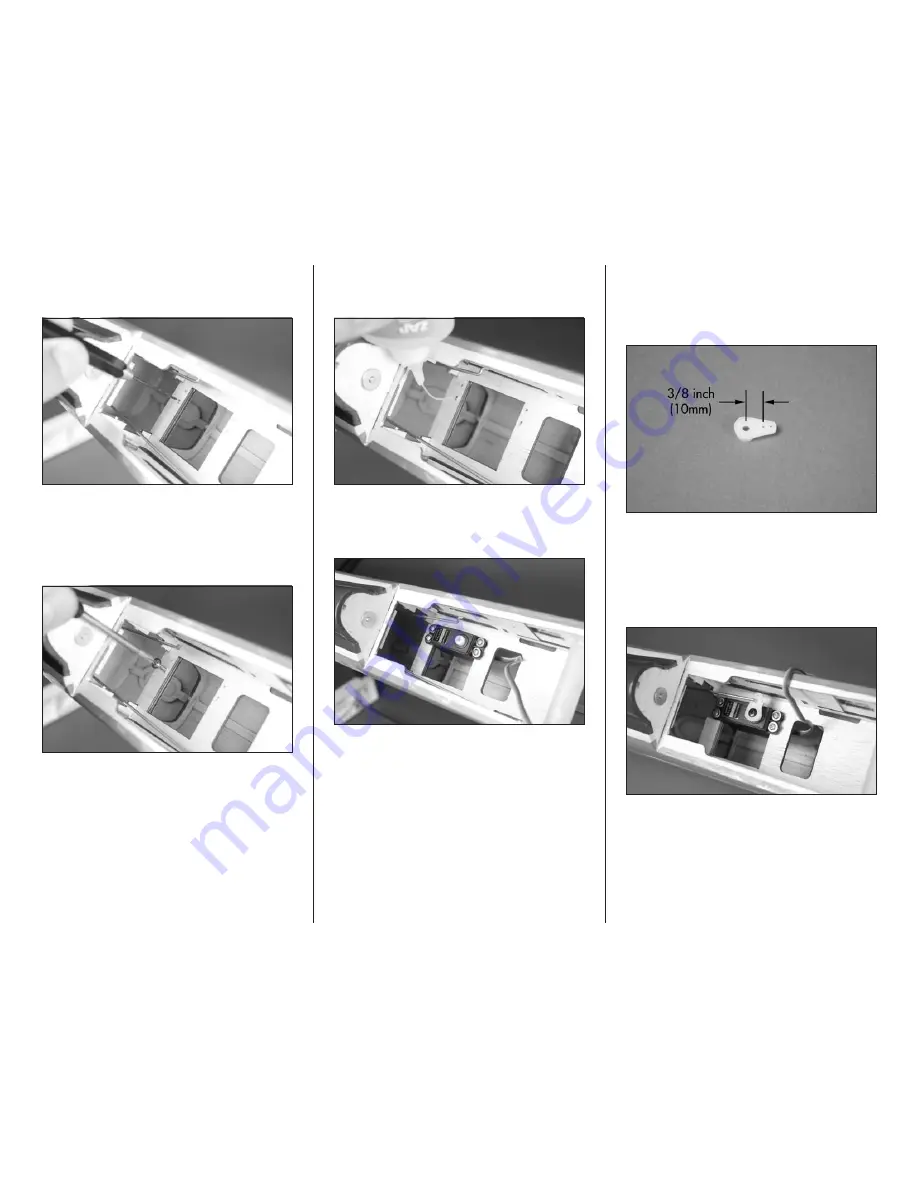

2. Remove the servo from the fuselage. Use a pin

vise and 1/16-inch (1.5mm) drill bit to drill the four

holes for the servo mounting screws.

3. Use a #1 Phillips screwdriver to thread a servo

mounting screw into each of the holes to cut threads

in the surrounding wood. Remove the screw before

moving to the next step. Prepare all four mounting

holes at this time.

4. Place 2–3 drops of thin CA in each hole to

harden the surrounding wood. This harder surface

makes the screws more secure when installed.

5. Return the servo to the fuselage. Use a #1 Phillips

screwdriver and the screws provided with the servo

to secure it in the fuselage.

6. Use a pin vise and 5/64-inch (2mm) drill bit

to enlarge the hole in the servo arm 3/8 inch

(10mm) from the center of the servo horn. Remove

the arms from the servo horn that will not be used

using side cutters.

7. Insert the Z-bend from the pushrod wire through

the hole in the servo horn. Use the radio system to

center the rudder servo. Install the servo horn so

it is perpendicular to the servo center line. Secure

the horn using the screw from the servo and a #1

Phillips screwdriver.