18

E-flite Super Cub 25e ARF Assembly Manual

Stabilizer and Tail Bracing Installation

Required parts

Fuselage assembly Stabilizer (right and left)

2-56 x 6

1

/

2

-inch threaded rod (2)

2-56 x 6

3

/

4

-inch threaded rod (2)

4-40 x 5/8-inch socket head cap screw (3)

4-40 x 1/4-inch socket head cap screw (2)

4-40 lock nut (3)

Nylon brace end (8)

Carbon rod, 5

1

/

8

-inch (130mm)

Carbon rod, 3

9

/

16

-inch (90mm)

Required Tools and Adhesives

Pin vise

Drill bit: 7/64-inch (3mm)

Threadlock

Hex wrench: 3/32-inch

Toothpick

Nut driver: 1/4-inch

30-minute epoxy

Paper towel

Isopropyl alcohol

Square

Sandpaper

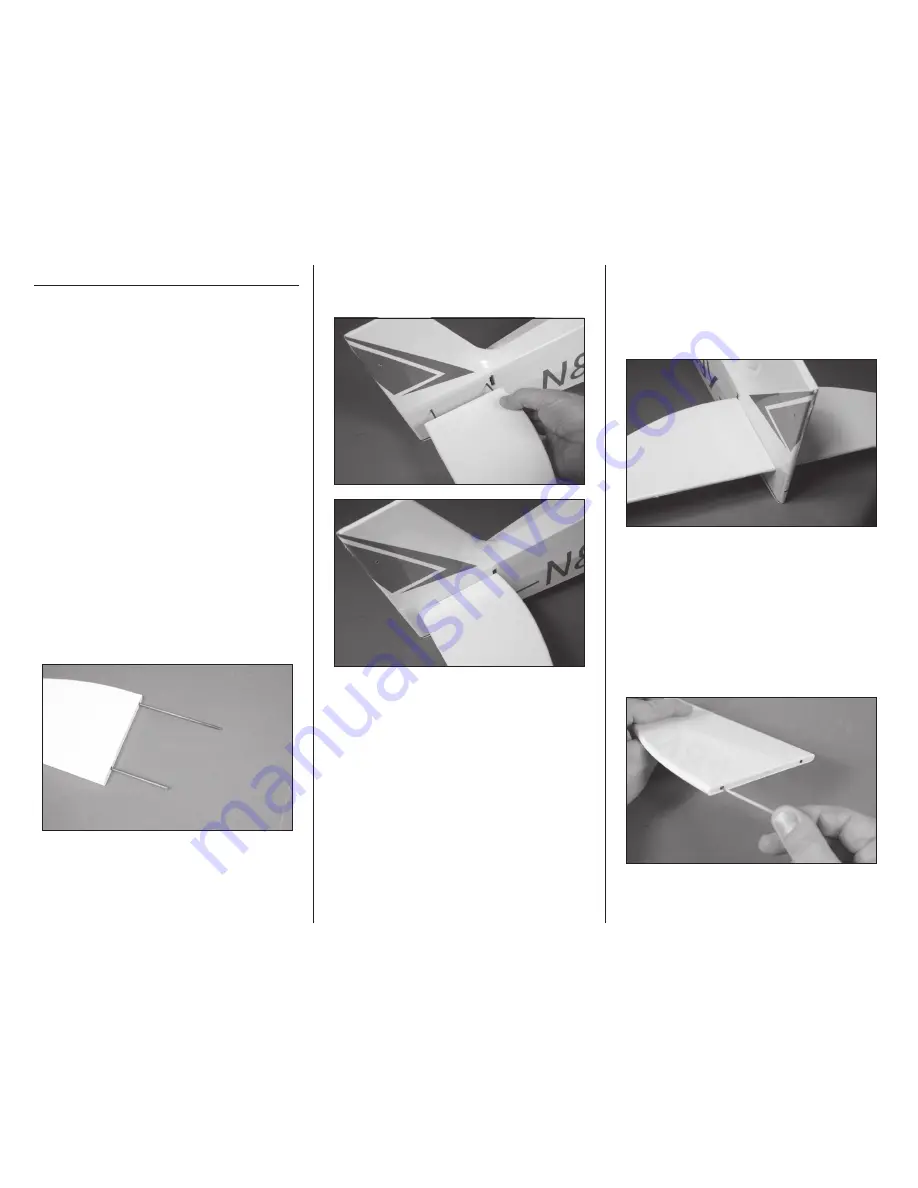

1. Slide the carbon fiber rods into the sockets in the

horizontal stabilizer. The longer 5

1

/

8

-inch (130mm)

rod is placed toward the front, while the shorter 3

9

/

16

-

inch (90mm) rod is positioned toward the trailing

edge. There are caps in the ends of the sockets for the

carbon rod spars. Do not force them in any farther

than they will easily slide.

2. Slide the stabilizer into position, guiding the

carbon rods through the holes in the fuselage. Slide

the stabilizer so it is tight against the fuselage.

3. Test the fit of the remaining stabilizer on the

stabilizer rods. Both stabilizers must fit snug against

the fuselage as shown. If not, determine the problem

and correct it before proceeding. Do not assume

that the rods are too long and shorten them. The

stabilizer relies on these for structural integrity.

4. Once the fit has been checked, remove the

stabilizers and carbon rods. Use sandpaper to

lightly sand each of the carbon rods. Mix a small

amount of 30-minute epoxy. Use a toothpick to

apply the epoxy in the holes for the carbon rods in

both stabilizer halves and the fuselage. Place the

stabilizers and carbon rods back into position and

allow the epoxy to fully cure before attaching the

bracing. Remove any excess epoxy before it cures

using a paper towel and isopropyl alcohol.