3

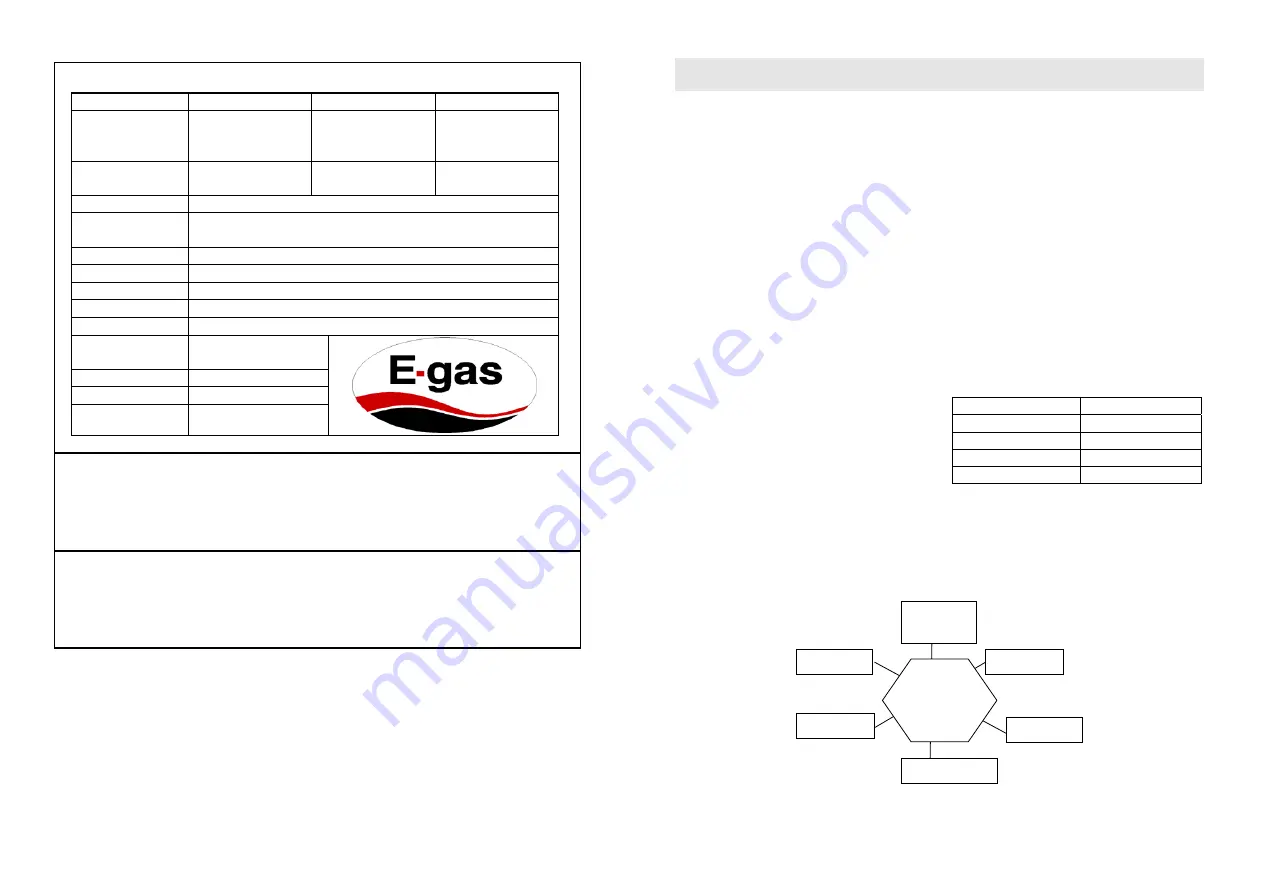

2.2 Main Technical Data & Features

Item Value Item

Value

Rated Thermal

Burden (kW)

24

Rated hot water

producing capacity

L/min (

Δ

t = 25 °C)

12

Working Voltage

(V.DC)

3 Power

Voltage

(V.DC) 3

Distributor:

E – Gas Systems

Appliance Model

& Size (mm)

JSD 12 E

819 x 395 x 245

Appliance Type B

B 11BS LPG Operating Pressure: 2.8 kPa

Certification Number:

I 1810

Type of Gas

G20 – 20 mbar

G31 – 37 mbar

Jet Size

0.67 mm

Gas Consumption

1.1 kg/hour

Nominal/minimum

Useful Output

P = 6.4 kW

Nominal Heat Input

Q = 16 kW

Max.

Water Pressure 7.5 bar

Min. Water Pressure: 0.25 bar

Features:

This model

has

accidental flameout safety device, vent pipe anti-block.

Must read the instruction manual before installing and using this appliance and operate it completely according

to the instruction manual.

Warning:

1. Read the technical instructions before installing the appliance.

2. Read the user’s instructions before lighting the appliance.

3. This appliance may only be installed in a room if the room meets the appropriate ventilation requirements.

2.3 Description of Control Functions

Winter/Summer Knob:

Used to switch from winter mode to summer mode or in a clockwise direction. If it

is in the summer mode, the gas diffusing into the main burner will be cut off and the energy of combustion

will decrease, in this way the gas will be saved in the summer mode.

Water Knob:

Used to switch between maximum water flow and minimum water flow.

Gas Knob: U

sed to switch between maximum gas and minimum gas feed.

4

3. INSTRUCTIONS FOR THE INSTALLER

3.1 Technical

Information

3.1.1

The installation, the adjustments and

maintenance listed in this part must only be carried

out by qualified installer. The manufacturer cannot be

held responsible for any damage to persons or things

deriving from an incorrect installation of the appliance.

3.1.2 The safety and automatic adjustment devices

of the appliance may only be modified or exchanged

by the manufacturer or duly authorised supplier.

The flue pipe anti-block device is a thermostat which

is fixed on the left side of flue outlet on the smoke

cover. When the flue pipe is blocked, the temperature

of the flue outlet will rise. After it is risen to a rated

value, the sensor in the thermostat will start to break

the circuit and cause the igniter stop. It must be

understood that the igniter is the main controller in the

machine, so if the circuit is broken, the

electromagnetic valve will stop working automatically,

and the ignition needle will also stop igniting. After

cleaning the flue pipe (we advise you to ask our after

sale service centre to help you), please press the

reset button to restart the sensor in the thermostat,

only in this way, it is safe to restart your gas water

heater.

3.2 Installation

3.2.1

Attention:

Water heater should be installed by

a registered gas appliance installer, carrying out the

installation in strict conformity to the manufacturer's

instructions and local bylaws to avoid any danger.

3.2.2 Position of Installation

INSTALL WATER HEATER OUTSIDE OF THE

BATHROOM

The water heater should be installed in an individual

room, separate from the bathroom and family living

room. Keep the room well ventilated so as to avoid

toxicosis by carbon monoxide. The air rate necessary

for discharge of combustion gas is listed as follow:

Heat Input ( kW)

Min Gas Output

(

v/s

)

≤

12 16

v/s

12~16 20

v/s

16~20 24

v/s

20~26 30

v/s

INSTALL IN A SEPARATE ROOM

NO

INSTALLATION

Stair and

safety exit

Cabinet

Bathroom

Living room

Bedroom

Basement