Manual SCA-SE-30-06

V 0.9

10/02 page 8

e-motion Gesellschaft für Antriebstechnik mbH, Zettachring 2, D-70567 Stuttgart, Germany

Tel.: +49-(0)711-7221535, Fax.: +49-(0)711-7221548 E-mail: mgmt@e-motion-controls.com

6. Configuration

For correct function please consider the required setting of

•

Operation mode

•

Input for Set Value

•

Maximum input frequency of encoder

and place the according jumpers at the front side of the drive, where :

* means...set Jumper -- means remove Jumper.

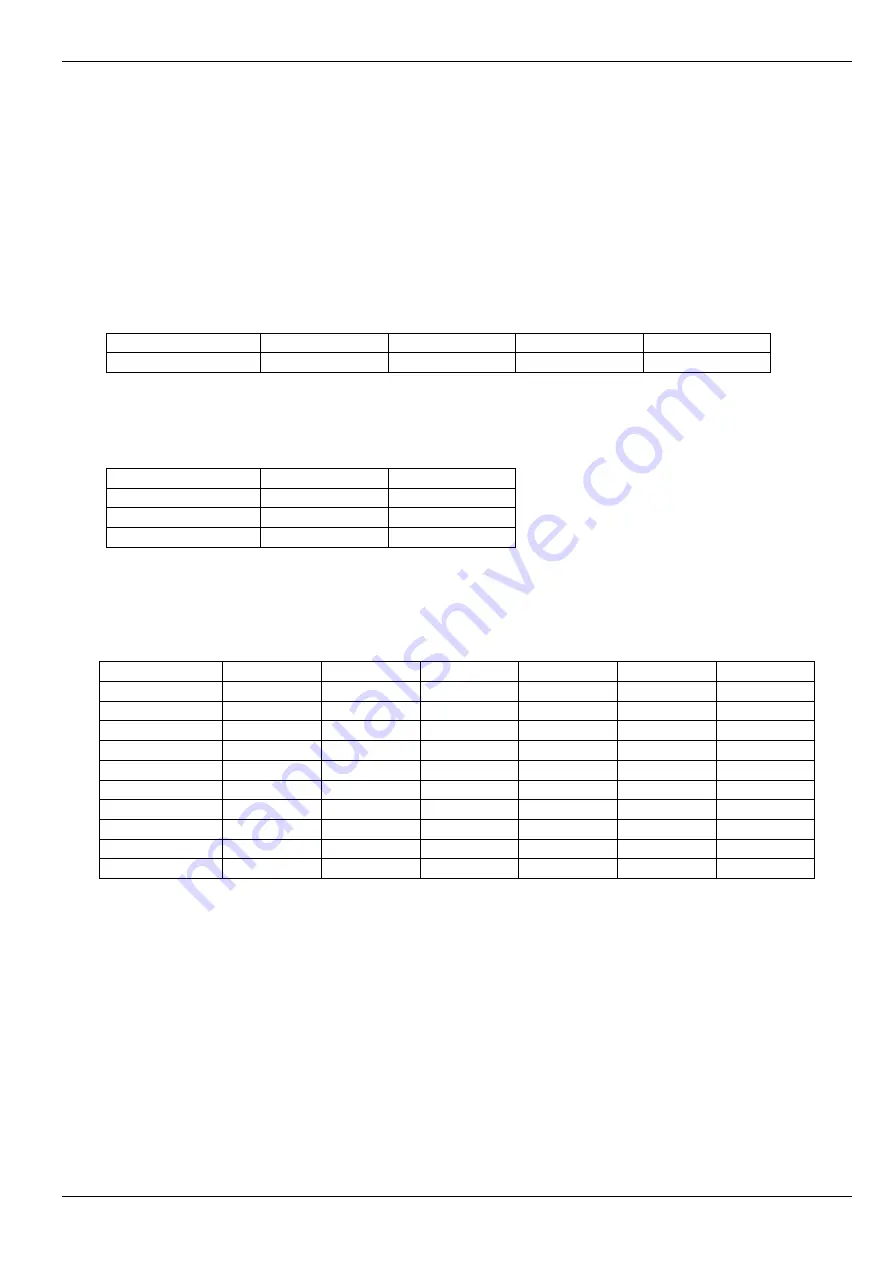

6.1. Selection of Operating mode (Jumper 1 - 4)

Operating mode

J1

J2

J3

J4

Encoder feedback

*

--

--

--

Other operating modes than encoder feedback are described in the manual SCA-SS-30-06

6.2. Selection of Input for Set Value (Jumper 5 – 6)

J5

J6

Via Offset Pot

*

*

Via Ext. Pot

*

--

Via Set Value

--

--

6.3. Selection of maximum input frequency of encoder module(Jumper 7 – 12)

n_max * resolution

frequency_max =

--------------------------

60

frequency_max

J12

J11

J10

J9

J8

J7

600kHz

--

--

--

--

*

--

300kHz

--

--

--

--

*

*

150kHz

--

--

--

--

--

--

75kHz

*

--

--

--

--

*

60kHz

*

--

--

*

*

--

30kHz

*

--

*

*

*

*

15kHz

*

--

--

*

--

--

7,5kHz

*

--

*

*

--

*

6kHz

*

*

--

*

*

*

1,5kHz

*

*

--

*

--

*

J12 is responsible for the filtering of the output signal of the encoder/tacho conversion module. If it is

set, the quality of the signal is better but the dynamic range is reduced due to the lowpass response.

Example:

resolution 500 counts per revolution (cpr)

nmax = 2520 round per minute (rpm)

maximum frequency: (2520 rpm * 500cpr) / 60 = 21000 Hz = 21 kHz

jumpers 7,8,9 and 10 have to be placed to get the desired signal