54

07/10

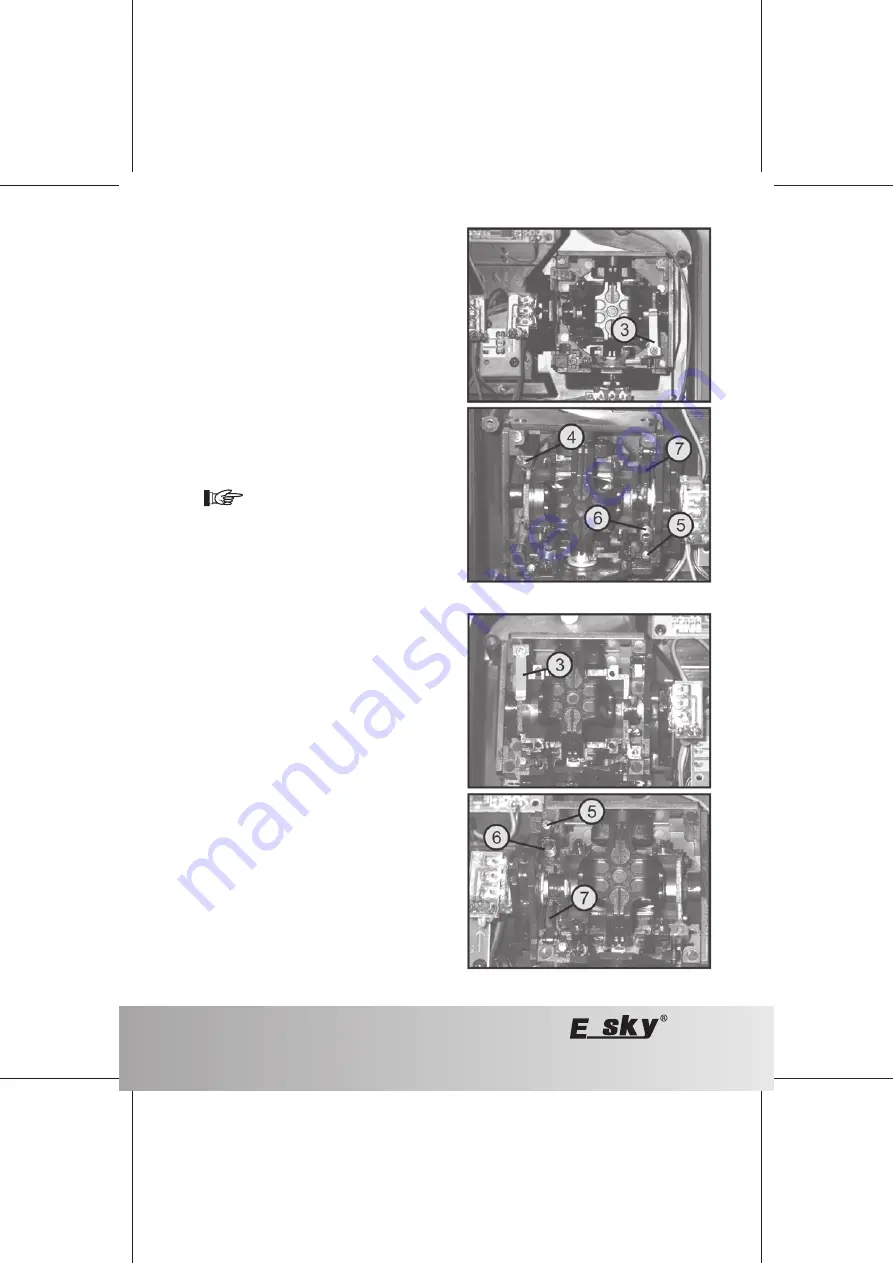

Figure 16

Figure 17

Mechanical conversion (only when switching the pitch

and nod functions)

Seen from the rear, loosen the stop spring (3) from the right

control lever aggregate and screw it on mirror-inverted to

the left control lever aggregate (seen from the rear) to the

attachment (4) (also see figure 17, top).

Loosen the adjuster screw (5) at the left control lever

aggregate (seen from the rear) for the restoring force of the

nod control stick so far that the traction spring (6) is as slack

as possible.

Now you can easily lift the screw together with the adjustment

mechanics upwards, disconnect the traction spring (4). Then

the complete setting mechanics can be easily lifted from

the guide.

Finally, lift out the return lever (7) together with the tension

spring (6).

Before you insert the release lever together with

the tension spring (seen from the rear) on the

right control stick aggregate, it makes sense to

fix the spring on the release lever with some in-

stant adhesive. This way, it remains at an exact

90° angle to the lever and only needs to be

inserted at the upper end.

Slide the return lever (7) below the horizontal shaft of the

right control stick lever with the glued-on spring (6) to the

front.

Then slide the screw (5) with the setting mechanics into the

prepared guide.

You best fix the tension spring in place with a thin wire or a

needle with a small catch on the tip.

When the spring was inserted, you can adjust the desired

control lever return force with the setting screw (5) and then

reattach the transmitter rear.

Finally, perform a function control of the entire system.