- 5 -

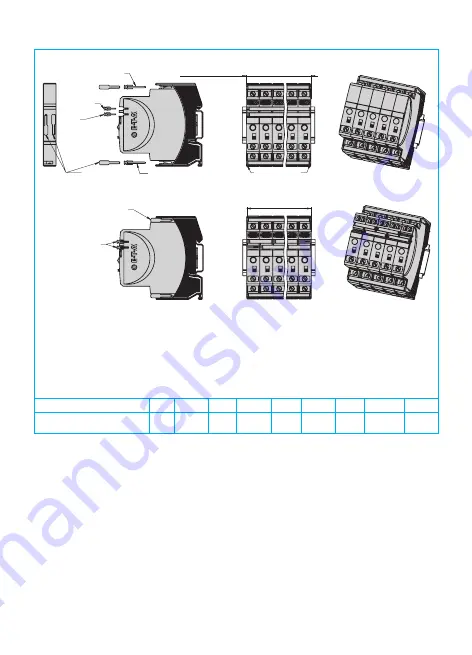

Mounting examples for ESX10-T

5 ESX10-TA

with busbars

5 ESX10-TB

with busbars

and jumpers

12.5 x n = width of protector block

e. g. 12.5 x 5 = 62.5

insert busbars

and protection slides

to be flush with housing sides

insert signal bars to

be flush with housing

and place them centrally

over the contacts

LINE+ busbar

X22261102 grey

or X222611xx

0 V busbar

X22261102 grey

or X222611xx

signal bar

X22200503 grey

or X222005xx

or

jumper

X22200513 grey

remove protection

against brush contact

from bottom side

(12.5 x n)-3 = length of busbars ± 0.5

e. g. (12.5 x 5)-3 = 59.5 ± 0.5

insert protection

against

brush contact

continuous busbar

500 mm length, cut

Mounting procedure:

Before wiring insert busbars into protector block.

Max. 10 insertion/removal cycles for busbars.

Recommendation:

After 10 units the busbars and signal busbars should be interrupted and receive a new entry live

Table of lengths for busbars

(X 222 611 02 / X 222 005 03 or cut off, see accessories)

No. of units

2

3

4

5

6

7

8

9

10

Length of busbar (mm) ± 0.5 mm

22

34.5

47

59.5

72

84.5

97

109.5

122

Summary of Contents for ESX10-TA-DC 24 V

Page 7: ...7...