25

4.3 Load outputs – Current limitation, inrush handling and soft start

In order to be able to switch loads with a high current rating, it is possible to connect load outputs of the SCS1000 and SCS3000

modules in parallel on the software side. Several outputs can be declared as a »team« via the configuration software.

All load outputs of the SCS1000 and SCS3000 are internally short circuit and thermally protected and have additional SMD fuses

on the PCB.

Besides the configurable, active current limitation, the SCS modules support a multilevel control of inrush currents. This behaviour

can be adjusted via the software.

Additionally, the SCS1000 and SCS3000 provide a diagnosis output with related reset input, which can also be configured via the

PDUsetup software. The output is then used to connect an LED to ground.

Compared to the SCS1000, the SCS3000 modules have additional multifunctional outputs, that can be used as high side or low

side outputs or as H-bridges. Furthermore, PWM up to a frequency of 20 kHz is supported.

The SCS3000 modules allow to realise a configurable soft start. This helps reduce high or intermittent cut-in currents, that can occur

during the switching of high electrical loads, e. g. inductive loads, cooling fans, electric motors or coolers. When implementing

start-up characteristics, inductive and resistive loads can be differentiated and the soft start behaviour can be adjusted accordingly.

4.4 Physical inputs

The SCS1000 and SCS3000 modules have inputs that can be used as digital or analogue inputs.

The analogue inputs of the devices cover a voltage range of 0 – 32 VDC. The measured value resolution is determined on 0.2 V by

default. To achieve higher accuracy, a resolution of 0.02 V can also be selected. With this setting, however, only voltage values up

to 5 V can be displayed and sent within a CAN message.

In addition, some inputs have internal 3 kΩ pull-up resistors to 5 V, which can be activated in the software to make the pins usable

as thermistor inputs.

The module reads the voltage applied to the inputs and sends it as a CAN message to other bus devices. Sensors, that are installed

in the proximity of the module, can easily be connected to the CAN bus via analogue inputs.

In addition, the data at the inputs can be further processed within the module, for example, to switch load outputs depending on

analogue inputs, or to control the duty cycle of a PWM output.

All SCS3000 power distributors also have a dedicated wake input that can be used to wake the module from deep sleep mode

on the hardware side. Furthermore, up to four additional inputs can be assigned with a wake-up function. These settings can be

made via the PDUsetup software.

4.5 Communication interfaces

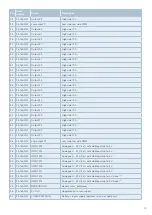

SCS1000-16…

•

1 x CAN 2.0B, J1939 compatible

For control and data transmission, as well as for configuration and firmware updates

SCS3000-…

• 3 x CAN 2.0B, J1939 compatible

For control and data transmission (frames to be sent per CAN channel selectable), as well as for configuration and firmware

updates

• 2 x 100 Mbit/s full duplex Ethernet

For module configuration and firmware updates, as well as live monitoring in the system, can also be used as an Ethernet

switch

• 1 x RS232C Serial interface

For the connection of external accessories

• 1 x LIN Bus

Upon request

Do not apply more than 13 VDC to the RS232C interface of the SCS3000 modules, otherwise the device may be damaged.