b. If out of specification, rebore or replace the

cylinder, and replace the piston and piston

rings as a set.

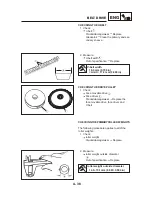

c. Measure piston skirt diameter “P” with the

micrometer.

5 mm (0.20 in) from the bottom edge of the pis-

ton

d. If out of specification, replace the piston and

piston rings as a set.

e. Calculate the piston-to-cylinder clearance

with the following formula.

f. If out of specification, rebore or replace the

cylinder, and replace the piston and piston

rings as a set.

Cylinder bore “C”

47.00 ~ 47.01 mm

(1.8504 ~ 1.8508 in)

Taper limit “T”

0.05 mm (0.002 in)

Out-of-round “R”

0.01 mm (0.0004 in)

“C” = maximum of D

1

~ D

2

“T” = maximum of D

1

or D

2

–

maximum of D

5

or D

6

“R” = maximum of D

1

, D

3

or D

5

–

minimum of D

2

, D

4

or D

6

Piston size “P”

Standard

46.97 ~ 46.99 mm

(1.8492 ~ 1.8500 in)

Piston-to-cylinder clearance =

Cylinder bore “C” –

Piston skirt diameter “P”

Piston-to-cylinder clearance

0.010 ~ 0.040 mm

(0.0004 ~ 0.0016 in)

<Limit>: 0.10 mm (0.0039 in)

a

ENG

4 - 23

CYLINDER AND PISTON