CHECKING THE TRANSMISSION

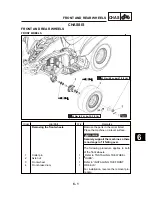

1. Measure:

counter shaft runout

(with a centering device and dial gauge )

Out of specification

Replace the counter

shaft.

Counter shaft runout limit

0.08 mm (0.0031 in)

2. Measure:

drive shaft runout

(with a centering device and dial gauge )

Out of specification

Replace the drive

shaft.

Dirve shaft runout limit

0.08 mm (0.0031 in)

3. Measure:

final shaft runout

(with a centering device and dial gauge )

Out of specification

Replace the final

shaft.

Final shaft runout limit

0.08 mm (0.0031 in)

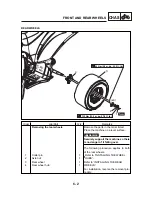

4. Check:

transmission gears

Blue discoloration/pitting/wear

Replace

the defective gear(s).

5. Check:

transmission gear engagement

(each pinion gear to its respective wheel

gear)

Incorrect

Reassemble the transmission

shaft assemblies.

6. Check:

transmission gear movement

Rough movement

Replace the defec-

tive part(s).

•

•

•

•

•

•

ENG

4 - 56

TRANSMISSION