8. V-BELT DRIVING SYSTEM/KICK STARTER ARM E-TON

8-8

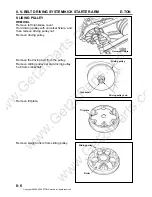

Apply with grease 4~5 g to inside of driving

shaft hole, and install driving pulley hub.

Caution

Install siding pulley assembly onto crankshaft.

Driving pulley install

Press driving belt into pulley groove, and

then press down the up & down sides of the

driving belt to separate it away from the

driving pulley hub.

Caution

Install driving pulley, washer and nut.

Caution

Hold driving pulley with universal fixture.

Tighten nut to specified torque.

Torque value: 5.0~6.0 kgf-m

Install left crankcase cover.

The pulley surface has to be free of

grease. Clean it with cleaning solvent.

Make sure that two sides of pulley

surfaces have to be free of grease.

Clean it with cleaning solvent.

To press down the up & down sides of

the driving belt can avoid to pressing and

damaging the belt when installing the

driving pulley, and also can make sure

that the driving pulley can be tighten.

Pulley surface

Crankshaft

Pulley hub

Sliding pulley

Driving belt

Press down

Universal fixture

Copyright ©2008-2009 ETON America, all rights reserved.

www.Get2itParts.com

www.Get2itParts.com

www.Get2itParts.com