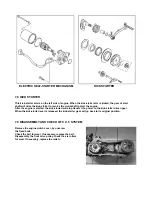

6.2 CYLINDER AND PISTON REMOVAL

Remove the seat and rear fender.

Remove the exhaust pipe.

Remove the spark plug cap.

Disconnect the wire.

Drag out the engine.

Disassembly the air cleaner and carburetor.

Remove the intake pipe mounting bolts.

Remove the cylinder bolt nuts.

Remove the cylinder head.

Remove the cylinder carefully, then you can see

the whole piston.

Remove one piston pin clip.

Remove the piston and piston pin.

Spread each piston ring and remove it by lifting up

at a point just opposite the gap.

Note: Don’t let the clip drop into engine crankcase.

6.3 CYLINDER AND PISTON INSPECTION

Inspect the cylinder bore for wear or damage.

Measure the cylinder inner diameter at three levels

in X and Y-axis.

Taper limit: 0.10 mm

Out of round: 0.10 mm