FUEL SYSTEM

Read all of Section B and this section before attempting any procedure. Pay particular attention to all Notes, Cautions and Warnings

As the pistons move down in the cylinders, a positive

pressure is formed in the crankcase which causes the

diaphragm to move in the opposite direction (away from

the engine). This action forces the inlet valve to close

and the outlet valve to open and supply fuel to the carbu

retor float bowl.

Fuel Pump Replacement

Tool List

Qty. Required

Socket, 7/16", 3/8" drive .............................................. 1

Ratchet, 3/8" drive ....................................................... 1

Needle nose pliers ....................................................... 1

Straight blade screwdriver ........................................... 1

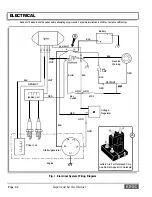

Observe and identify the supply and pulse hoses.

Remove the hoses, plug the fuel lines and remove the

pump by removing the two mounting screws (1) and

removing the pump (Ref Fig. 7 on page H-6).

Installation is in the reverse order of disassembly. Be

sure to connect the pulse line to the correct location on

the pump (Ref Fig. 7 on page H-6).

Fig. 7 Fuel Pump Installation

I

NOTE

I

The length of the pulse hose from the fuel

._ ___ _,

pump is important for efficient pump operation.

If the hose is to be replaced, be sure to replace with a hose of

the same length and approved material.

CAUTION

Do not confuse pulse and fuel lines.

Attempting to operate engine with lines

reversed will result in fuel entering the crankcase and diluting

the oil and possible engine damage.

FUEL LINES AND FILTER

Tool List

Qty. Required

Needle nose pliers ....................................................... 1

Straight blade screwdriver ........................................... 1

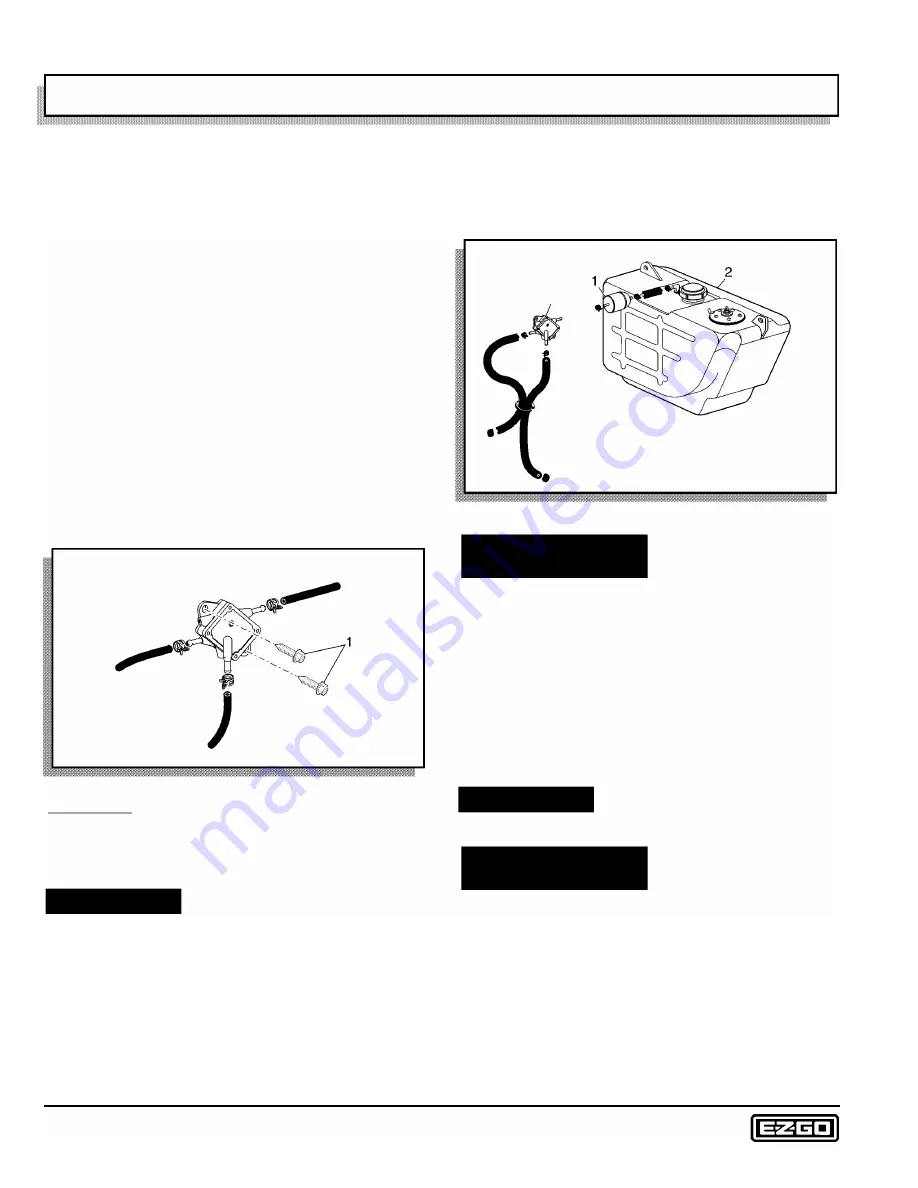

Fuel is supplied to the fuel pump and carburetor through

flexible fuel hoses. An in-line filter (1) is installed in the

hose between the fuel tank (2) and the fuel pump (3) (Ref

Fig. 8 on page H-6).

3

.-

Fig. 8 Fuel Lines and Filter

A

WARNING.A.

Tests that involve fuel

flow should be avoided if

at all possible. If a test to

determine fuel/vapor presence or flow is required, the

ignition system must be disabled. Remove the input

wires to the coil in order to prevent an ignition spark

that could ignite the fuel/vapor. Never permit smoking

or an open flame in an area that contains fuel/vapor.

Clean up all fuel spills immediately.

The fuel filter, tank, hoses and cap should be checked

frequently for leaks, or signs that the cap vent or filter

have become clogged. The filter should be replaced as

required. See Periodic Service Schedule in Section A.

CAUTION

towards the fuel pump .

The filter is marked with a flow direction

arrow. Be sure that the arrow points

A

WARNING.A.

Never attempt to repair a

damaged or leaking fuel

tank. It must be replaced.

FUEL AND STORAGE

Fuel should be fresh, clean unleaded 87 (minimum)

octane.

Methanol and other alcohol based fuels are hygroscopic

fuels which attract and retain moisture. These types of

fuels can attack the aluminum fuel pump and carburetor,

and should be avoided.

Page H-6

Repair and Service Manual

Summary of Contents for 4 CADDY 1999

Page 6: ...TABLE OF CONTENTS Notes __________________________ _ Page iv Repair and Service Manual...

Page 10: ...SAFETY INFORMATION Notes _________________________ _ Page viii Repair and Service Manual...

Page 26: ...SAFETY Notes _ _ ___________________________ _ Page B ii Repair and Service Manual...

Page 48: ...BODY Notes _ _ ___________________________ _ Page C ii Repair and Service Manual...

Page 56: ...WHEELS AND TIRES Notes __________________________ _ Page D ii Repair and Service Manual...

Page 72: ...SPEED CONTROL Notes _ _ ________________________ _ Page F ii Repair and Service Manual...

Page 80: ...ENGINE Notes _ _ __________________________ _ Page G ii Repair and Service Manual...

Page 94: ...FUEL SYSTEM Notes _ _ _________________________ _ Page H ii Repair and Service Manual...

Page 110: ...ELECTRICAL Notes _ _ _________________________ _ Page K ii Repair and Service Manual...

Page 120: ...ACCESSORY WIRING Notes __________________________ _ Page L ii Repair and Service Manual...

Page 148: ...REAR SUSPENSION Notes __________________________ _ Page N ii Repair and Service Manual...

Page 154: ...REAR AXLE Notes _ _ ___________________________ _ Page P ii Repair and Service Manual...

Page 158: ...PAINT Notes _ _ ___________________________ _ Page Q ii Repair and Service Manual...

Page 162: ...TROUBLESHOOTING Notes _ _ ________________________ _ Page R ii Repair and Service Manual...

Page 170: ...LIMITED WARRANTY Notes __________________________ _ Page S ii Repair and Service Manual...

Page 176: ...LIMITED WARRANTY Notes __________________________ _ Page S 6 Repair and Service Manual...

Page 178: ...GENERAL SPECIFICATIONS Notes _________________________ _ Page T ii Repair and Service Manual...