ELECTRICAL

Read all of Section B and this section before attempting any procedure. Pay particular attention to all Notes, Cautions and Warnings

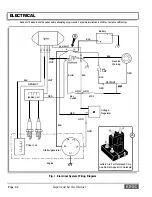

The charging circuit consists of a starter/generator, volt

age regulator and battery (Ref Fig. 1 on page K-2). The

solenoid must be functional in order to start the vehicle,

but is not considered part of the charging circuit.

1. If the battery charge is inadequate (less than 11

VDC), proceed as follows:

a) Check the battery voltage and inspect for loose or

corroded terminal posts and connections. Check

electrolyte level.

b) Check charging circuit component terminals for

proper, clean, tight connections.

c) Check for charging voltage as follows:

1) Raise the vehicle (see procedure in Section

B) so that both rear wheels are free to rotate.

2) With the engine off, measure the voltage at

the battery's terminals by placing the nega

tive(-) probe on the negative(-) post and the

positive ( +) probe on the positive ( +) post of

the battery. Note the reading.

3) Attach the DC voltmeter across the regula

tor's red and black leads.

4) Start the engine and accelerate to governed

speed.

5) The meter should read higher than before

starting the engine. In a reasonable amount

of time, the reading should settle between 14

and 15 volts, indicating the regulator is func

tioning properly.

6) If no increase over battery voltage is

observed, there is a malfunction in the

charging circuit.

7) If the reading is

above

15 volts, check to

assure the wiring harness and generator

field winding (green lead) is not grounded. If

it is not, replace the regulator.

8) If the reading is

below

14 volts, disconnect

the regulator's green field wire from the sys

tem harness. Temporarily connect the green

field wire to ground. If the voltage rises

above its prior reading, replace the regulator.

9) If the above procedures do not correct the

problem, check for faults in the vehicles wir

ing harness and/or generator.

STARTER/GENERATOR

Starter/Generator Removal

See ENGINE section.

Starter/Generator Disassembly

Tool List

Qty. Required

DVOM .......................................................................... 1

Wrench, 24 mm ........................................................... 1

Wrench, 10 mm ........................................................... 1

Wrench, 6 mm ............................................................. 1

Wrench, 5 mm ............................................................. 1

Socket, 10 mm, 3/8" drive ............................................ 1

Phillips screwdriver, 3/8" drive ..................................... 1

Two jaw puller ............................................................. 1

Straight blade screwdriver, ......................................... 1

Ratchet, 3/8" drive ....................................................... 1

I

NOTE

I

In general, start�r/generator servi�� is best

�-

---�-

performed by framed motor technicians who

have the knowledge and equipment to overhaul the unit. Some

checks and repairs however, can be accomplished by a skilled

mechanic. Make your own evaluation of the equipment and

skills available before starting disassembly.

Hold the pulley (1) and remove the pulley nut (2).

Remove the pulley, screws (4) and front cover (3) (Ref

Fig. 5 on page K-7).

Remove the brush covers (6) by prying out with a screw

driver. Pull up on the brush springs and move to the side

of brushes, slide the brushes out approximately 1/4" (6

mm) (Ref Fig. 6 on page K-7). Remove the through bolts

(7) and the rear cover (8). Remove the frame and field

coils (9). Remove the 5 mm screws from the brush holder

and 6 mm nuts from A 1 and A2 terminals. Remove the

brush holder. If the bearing needs to be replaced, use an

automotive style two jaw puller to remove the bearing

from armature (Ref Fig. 7 on page K-7).

Starter/Generator Inspection

1. Inspect the commutator for wear or damage.

2. Inspect the brush assembly for wear and damage to

the brush holder insulators. Check the brushes for

length, approximately 11/16" (17 mm) or to the line

marked on the brush and signs of carbonization.

3. Inspect the armature for distortion or broken wires.

4. Inspect the field coil insulators and lead wire.

5. Check the bearings for free rotation and lack of end

play on shaft. Replace if necessary.

Page K-6

Repair and Service Manual

Summary of Contents for 4 CADDY 1999

Page 6: ...TABLE OF CONTENTS Notes __________________________ _ Page iv Repair and Service Manual...

Page 10: ...SAFETY INFORMATION Notes _________________________ _ Page viii Repair and Service Manual...

Page 26: ...SAFETY Notes _ _ ___________________________ _ Page B ii Repair and Service Manual...

Page 48: ...BODY Notes _ _ ___________________________ _ Page C ii Repair and Service Manual...

Page 56: ...WHEELS AND TIRES Notes __________________________ _ Page D ii Repair and Service Manual...

Page 72: ...SPEED CONTROL Notes _ _ ________________________ _ Page F ii Repair and Service Manual...

Page 80: ...ENGINE Notes _ _ __________________________ _ Page G ii Repair and Service Manual...

Page 94: ...FUEL SYSTEM Notes _ _ _________________________ _ Page H ii Repair and Service Manual...

Page 110: ...ELECTRICAL Notes _ _ _________________________ _ Page K ii Repair and Service Manual...

Page 120: ...ACCESSORY WIRING Notes __________________________ _ Page L ii Repair and Service Manual...

Page 148: ...REAR SUSPENSION Notes __________________________ _ Page N ii Repair and Service Manual...

Page 154: ...REAR AXLE Notes _ _ ___________________________ _ Page P ii Repair and Service Manual...

Page 158: ...PAINT Notes _ _ ___________________________ _ Page Q ii Repair and Service Manual...

Page 162: ...TROUBLESHOOTING Notes _ _ ________________________ _ Page R ii Repair and Service Manual...

Page 170: ...LIMITED WARRANTY Notes __________________________ _ Page S ii Repair and Service Manual...

Page 176: ...LIMITED WARRANTY Notes __________________________ _ Page S 6 Repair and Service Manual...

Page 178: ...GENERAL SPECIFICATIONS Notes _________________________ _ Page T ii Repair and Service Manual...