OPERATION AND SERVICE INFORMATION

Page 17

Owner’s Manual and Service Guide

Read all of manual to become thoroughly familiar with this vehicle. Pay particular attention to all Notes, Cautions and Warnings

TIRE INSPECTION

Tire condition should be inspected per the Periodic Ser-

vice Schedule (Ref. Fig. 21 on page 16). Inflation pres-

sures should be checked when the tires are cool. Be sure

to install the valve dust cap after checking or inflating.

BRAKES

To reduce the possibility

of severe injury or death,

always evaluate pedal

travel before operating a vehicle to verify some brak-

ing function is present.

All driving brake tests must be done in a safe location

with regard for the safety of all personnel.

Over time, a subtle loss of performance may

take place; therefore, it is important to establish

the standard with a new vehicle.

The Periodic Brake Performance Test should be per-

formed regularly (Ref. Fig. 21 on page 16) as an evalua-

tion of braking system performance. It is useful as a

method of identifying subtle loss of performance over

time.

Periodic Brake Test for Mechanical Brakes

The purpose of this test is to compare the braking perfor-

mance of the vehicle to the braking performance of new

or ‘known to be good’ vehicles or to an established

acceptable stopping distance. Actual stopping distances

will be influenced by weather conditions, terrain, road

surface condition, actual vehicle weight (accessories

installed) and vehicle speed. No specific braking distance

can be reliably specified. The test is conducted by latch-

ing the parking brake to eliminate different pedal pres-

sures and to include the affects of linkage mis-

adjustment.

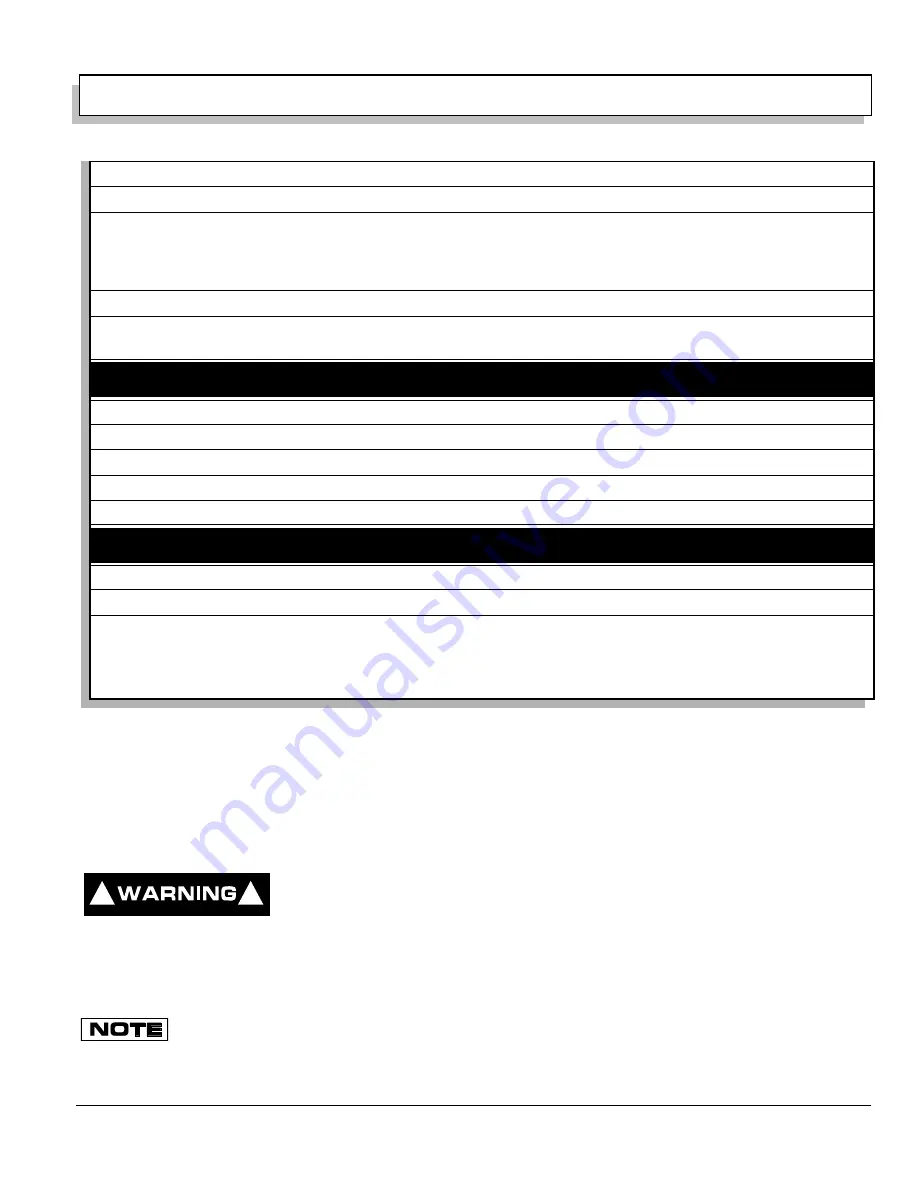

FRONT SPRINGS

✓

Check for loose hardware, cracks at attachments

FRONT WHEEL ALIGNMENT

✓

Check for unusual tire wear, align if required

PARK BRAKE

✓

Check for bent/binding linkage rod

✓

Check for damage or wear to latch arm or catch bracket

♦

Lubricate as required, use light oil. DO NOT LUBRICATE CABLES OR BRAKE

LATCH

REAR SHOCK ABSORBERS

✓

Check for oil leakage, loose mounting hardware

HARDWARE AND FASTENERS

✓

Check for loose or missing hardware and components

♦

Tighten or replace missing hardware

SEMI-ANNUAL - 125 HOURS

(includes items listed in previous tables & the following)

DIRECTION SELECTOR

✓

Check for wear and smooth movement (lubricate shaft with light oil if required)

KING PINS

✓

Check for excessive play and tightness of retaining nuts

STEERING ASSEMBLY

✓

Check bellows and pinion seal for damage or grease leakage

RACK END BALL JOINT

♦

Lubricate, use wheel bearing grease

REAR AXLE

✓

Check for unusual noise and loose or missing mounting hardware

ANNUAL - 250-300 HOURS

(includes items listed in previous tables & the following)

FRONT WHEEL BEARINGS

✓

Check and adjust as required, see Technician’s Repair and Service Manual

REAR AXLE

✓

Check lubricant, add lubricant (SAE 30 oil) as required

SERVICE BRAKES

(HYDRAULIC BRAKES)

♦

Clean and adjust, see Technician’s Repair and Service Manual

✓

Check brake shoe linings, see Technician’s Repair and Service Manual

✓

Check brake fluid

Fig. 21 Periodic Service Schedule

!

!

Summary of Contents for MPT 800

Page 1: ...ELECTRIC POWERED UTILITY VEHICLES ISSUED APRIL 2005 OWNER S MANUAL AND SERVICE GUIDE 28803 G01...

Page 8: ...Page vi TABLE OF CONTENTS Owner s Manual and Service Guide...

Page 12: ...Owner s Manual and Service Guide SAFETY INFORMATION Page x Notes...

Page 43: ...Page 27 GENERAL SPECIFICATIONS Owner s Manual and Service Guide GENERAL SPECIFICATIONS...

Page 50: ...Page 34 Owner s Manual and Service Guide GENERAL SPECIFICATIONS Notes...

Page 51: ...Page 35 Owner s Manual and Service Guide WARRANTY LIMITED WARRANTIES...

Page 54: ...Page 38 Owner s Manual and Service Guide WARRANTY Notes...

Page 56: ...Page 40 Owner s Manual and Service Guide DECLARATION OF CONFORMITY...

Page 58: ...Page 42 Owner s Manual and Service Guide DECLARATION OF CONFORMITY Notes...

Page 59: ...Appendix A 1 LABELS AND PICTOGRAMS Owner s Manual and Service Guide LABELS AND PICTOGRAMS...