Page 14

OPERATION AND SERVICE INFORMATION

Owner’s Guide

Read all of this manual to become thoroughly familiar with this vehicle. Pay particular attention to all Notes, Cautions and Warnings.

B

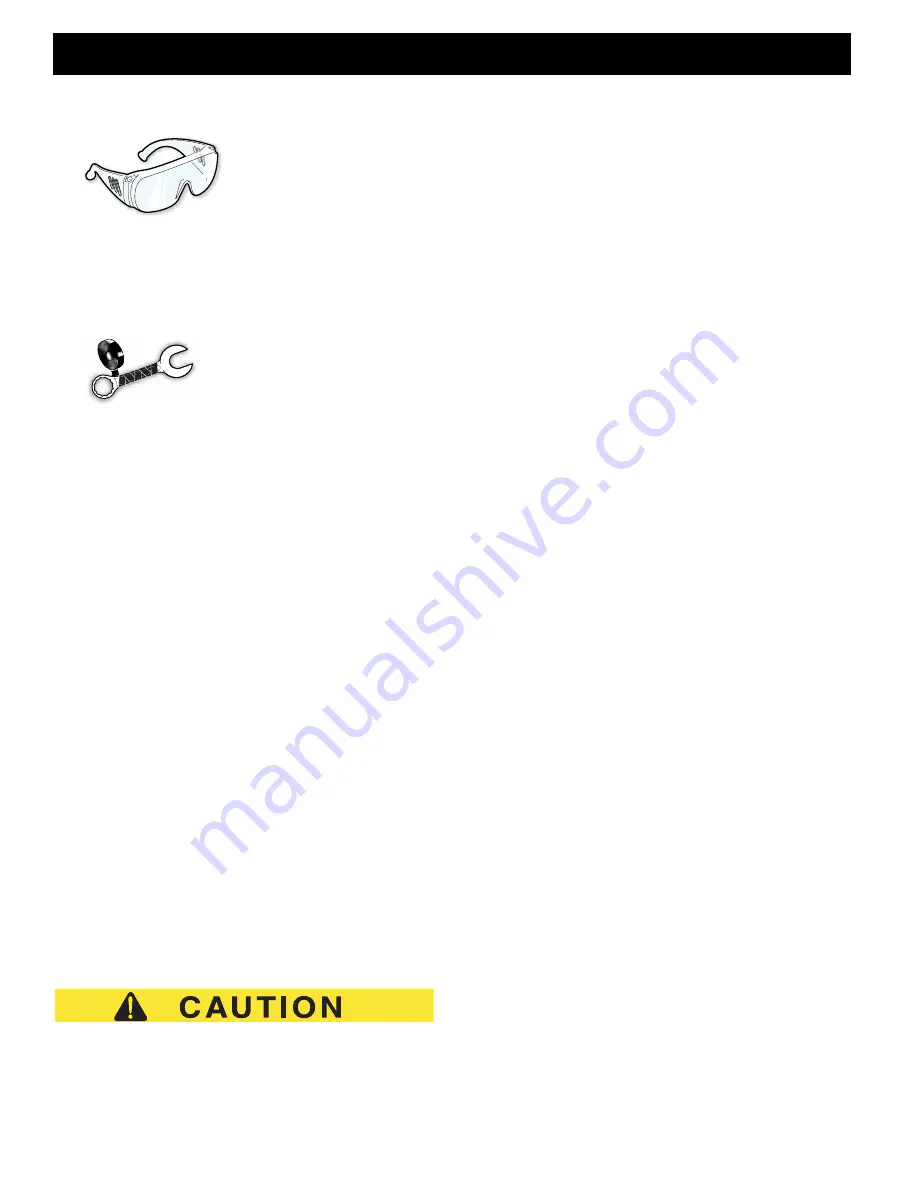

Wear eye protection

when working on the

vehicle. Use extra care

when working around

batteries, or using sol-

vents or compressed air.

To reduce the possibility of causing an

electrical arc, which could result in a battery

explosion, turn off all electrical loads from

the battery before removing battery wires.

Wrap wrenches with vinyl

tape to reduce the possibil-

ity of a dropped wrench

‘shorting out’ a battery,

which could result in an

explosion.

The electrolyte in a battery is an acid solu-

tion which can cause severe burns to the

skin and eyes. Treat all electrolyte spills to

the body and eyes with extended flushing

with clear water. Contact a physician imme-

diately.

Any electrolyte spills should be neutralized

with a solution of 2 teaspoons (10 ml) sodi-

um bicarbonate (baking soda) dissolved in

1 quart (1 liters) of water and flushed with

water.

Aerosol containers of battery terminal pro-

tectant must be used with extreme care.

Insulate metal container to reduce the pos-

sibility of can contacting battery terminals

which could result in an explosion.

It is in the best interest of both vehicle owner and ser-

vice technician to carefully follow the procedures recom-

mended in this manual. Preventative maintenance, ap-

plied at recommended intervals, is the best guarantee

for keeping the vehicle both dependable and economi-

cal.

This vehicle will give years of satisfactory service, pro-

viding it receives regular maintenance. Refer to the

Periodic Service Schedule for appropriate service inter-

vals (Ref. Fig. 19).

ROUTINE MAINTENANCE

To prolong vehicle life, some maintenance items must

be serviced more frequently on vehicles used under

severe driving conditions such as extreme tempera-

tures, extreme dust/debris conditions, frequent use

with maximum load.

To access the powertrain for routine maintenance, lift or

remove the seat and remove the rear access panel. For

major repair, refer to the appropriate Technician’s Repair

and Service Manual.

Some service procedures may require the vehicle to be

lifted. Refer to LIFTING THE VEHICLE for proper lifting

procedure and safety information.

TIRE INSPECTION

Tire condition should be inspected per the Periodic Ser-

vice Schedule. Inflation pressures should be checked

when the tires are cool. Be sure to install the valve dust

cap after checking or inflating.

REAR AXLE

The only maintenance required for the first five years is

the periodic inspection of the rear axle for lubricant leak-

age. Unless leakage is evident, the lubricant need only

be replaced after five years. Refer to the Service &

Repair Manual p/n 605975 for the fluid replacement pro-

cedure.

HARDWARE

Periodically, the vehicle should be inspected for loose

fasteners. Fasteners should be tightened in accordance

with the Torque Specifications table (Ref. Fig. 18).

Use care when tightening fasteners and refer to the

Technician’s Repair and Service Manual for specific

torque values.

Generally, three classes of standard hardware and two

classes of metric hardware are used in the vehicle.

Grade 5 hardware can be identified by the three marks

on the hexagonal head and grade 8 hardware is identi-

fied by 6 marks on the head. Metric hardware is marked

on the head with 8.8 or 10.9. Unmarked hardware is

Grade 2.

Summary of Contents for RXV Fleet Freedom Shuttle 2+2

Page 47: ...Page 27 Owner s Guide GENERAL SPECIFICATIONS GENERAL SPECIFICATIONS...

Page 55: ...Page 35 Owner s Guide WARRANTY LIMITED WARRANTIES...

Page 57: ...Page 37 Owner s Guide DECLARATION OF CONFORMITY DECLARATION OF CONFORMITY EUROPE ONLY...

Page 60: ...Page 40 Owner s Guide DECLARATION OF CONFORMITY...

Page 107: ...Seite 27 ALLGEMEINE TECHNISCHE DATEN ALLGEMEINE TECHNISCHE DATEN Betriebsanleitung...

Page 115: ...Seite 35 GARANTIE Betriebsanleitung BEGRENZTE GEW HRLEISTUNG...

Page 117: ...Seite 37 KONFORMIT TSERKL RUNG Betriebsanleitung KONFORMIT TSERKL RUNG NUR EUROPA...

Page 120: ...Seite 40 KONFORMIT TSERKL RUNG Betriebsanleitung...