OPERATION AND SERVICE INFORMATION

3-35

Read all of manual to become thoroughly familiar with this vehicle. Pay particular attention to all Notes, Cautions and Warnings

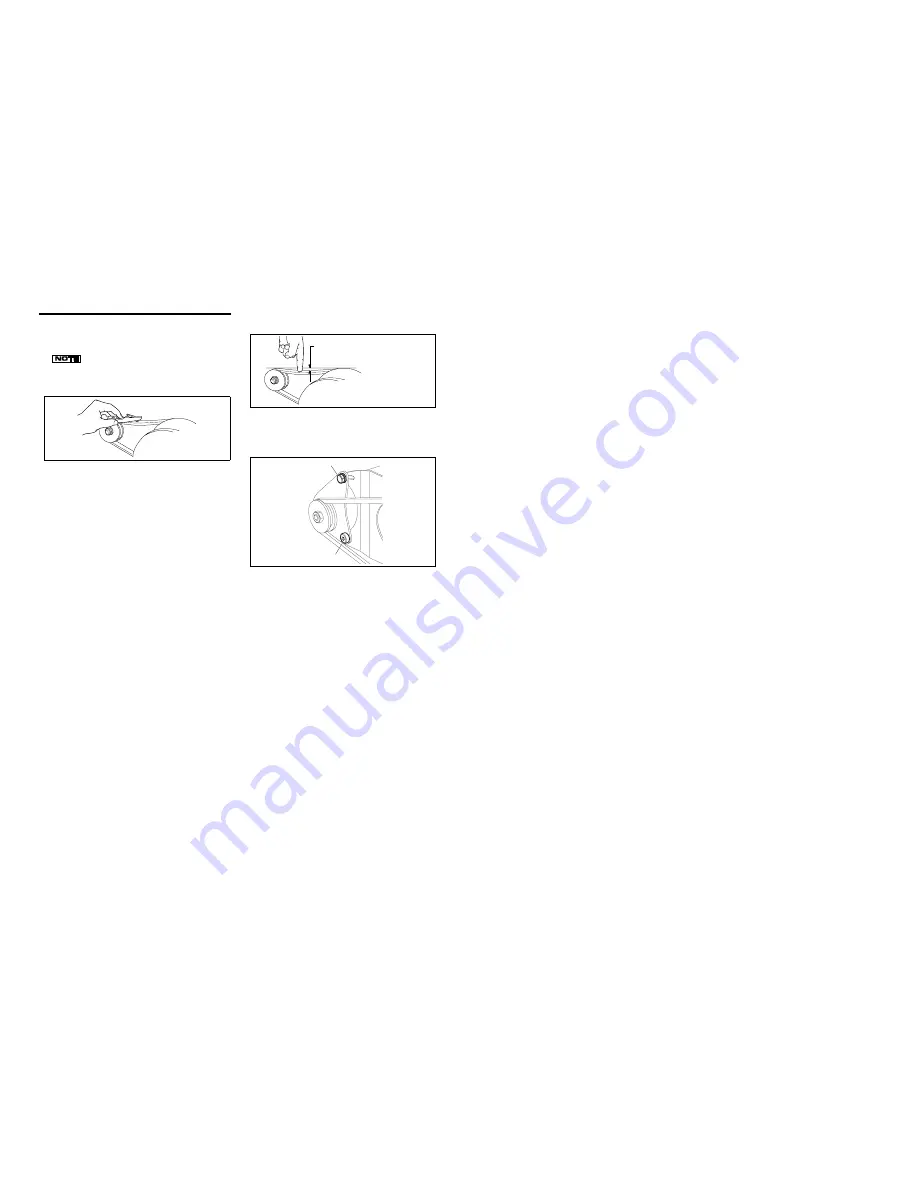

The starter/generator belt tension should be checked after the first 15-

20 hours of operation and set to 75 - 80 lbs. (34 - 36 kg).

A loose belt can cause audible vibration and

squeal.

Tighten a new starter/generator belt to 90 - 110 lbs. (41 - 50 kg) tension

when a gauge is applied half way between the two pulleys (Ref Fig. 32

on page 3-35).

Although not as accurate, the belt may be depressed with a finger. A

maximum deflection of 3/8" (1 cm) is acceptable for a new belt (Ref

Fig. 33 on page 3-35).

Tighten an existing belt to 75 - 80 lbs. (34 - 36 kg) tension using the

same technique and inspect for cracking or wear. A maximum deflec-

tion of 1/2" (13 mm) is acceptable.

Adjusting the Belt

Loosen front and back pivot bolts of starter/generator (Ref Fig. 34 on

page 3-35).

Loosen adjusting bolt. Use pry bar to force starter/generator towards

front of vehicle until proper belt tension is achieved. Hold starter/gener-

ator in place and tighten adjusting bolt.

Tighten pivot bolts to 25 ft. lbs. (35 Nm) torque.

Fig. 32 Check Belt Tension with Gauge

Fig. 33 Check Belt Tension with Finger

Fig. 34 Adjust Belt Tension

3/8" (1 cm) Max. Deflection for New Belt

1/2" (1.3 cm) Max. Deflection for Existing Belt

Pivot Bolt

Adjusting Bolt

Summary of Contents for ST 480

Page 1: ...A Textron Company...

Page 54: ...5 2 LIMITED WARRANTY Notes...

Page 55: ...6 1 DECLARATION OF CONFORMITY NOT AVAILABLE AT TIME OF PUBLICATION...

Page 56: ...6 2 DECLARATION OF CONFORMITY Notes...

Page 65: ......