Page G-1

Repair and Service Manual

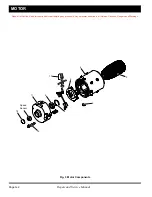

MOTOR

Read all of Section B and this section before attempting any procedure. Pay particular attention to all Notices, Cautions, Dangers and Warnings.

GENERAL

Do not hold vehicle on hill by using accelerator and

motor. Leaving the motor in a stalled condition for more

than 3-4 seconds will raise the commutator bars result-

ing in unacceptable noise and accelerated brush wear

and cause permanent damage to motor.

Disassembly of the motor is not recommended except to

replace a worn or noisy bearing. If the motor is disas-

sembled, it should be cleaned of any dirt buildup and the

brush length checked. Replace brushes if required.

Neither the motor housing nor armature is available as

service items, therefore in the unlikely event of a failure

in either of these components, the entire motor must be

replaced.

Motor Removal

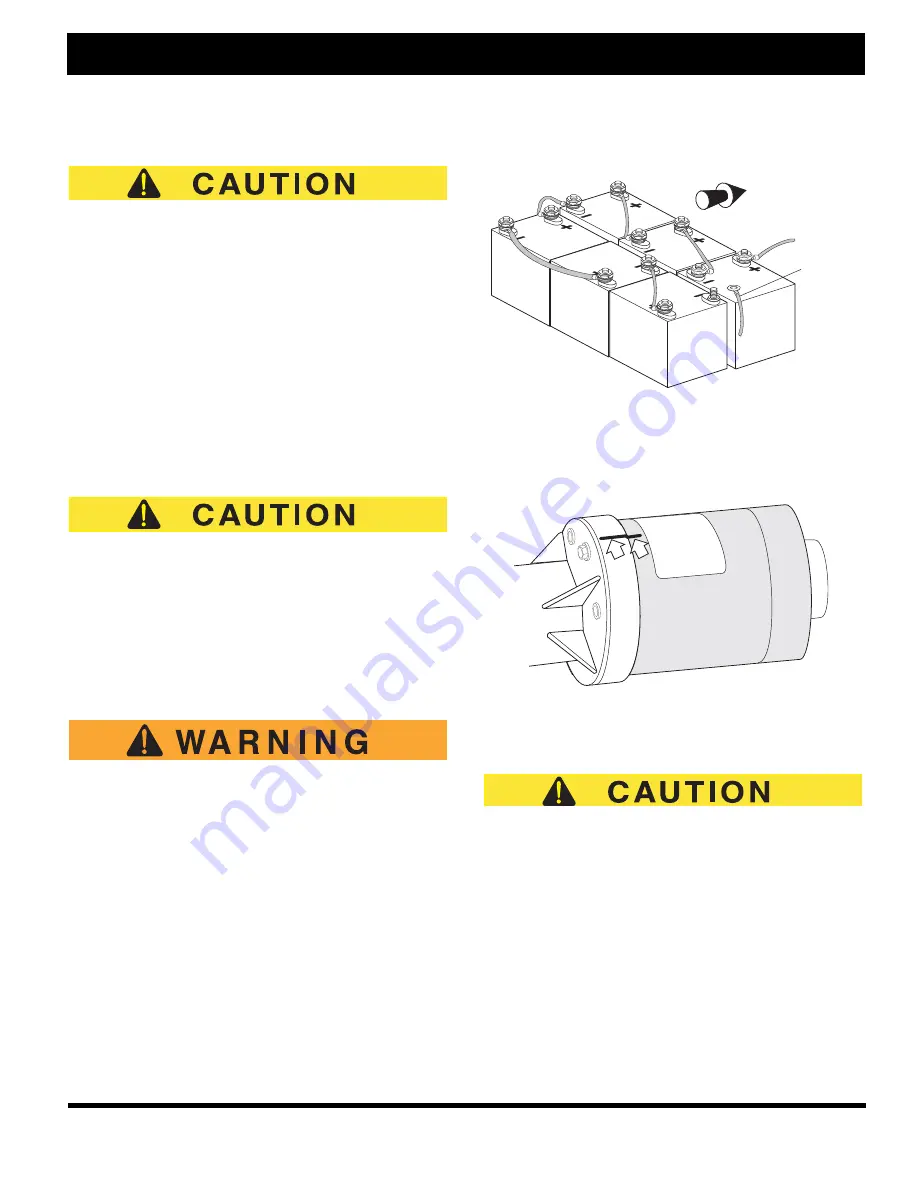

Before any electrical service is performed on TCT model

vehicles, the Run-Tow/Maintenance switch must be

placed in the ‘Tow/Maintenance’ position.

If a power wire (battery, motor or controller) is discon-

nected for any reason on the TCT model vehicle, the

Run-Tow/Maintenance switch must be left in the ‘Tow/

Maintenance’ position for at least 30 seconds after the

circuit is restored.

Disconnect the negative (BL-) battery cable

with an insulated wrench before attempting to

remove wires from the motor (see safety pro-

cedures in SAFETY section of this manual).

The shorting of motor wires could cause an

explosion.

Tool List

Qty. Required

Insulated wrench, 9/16"............................................... 1

Chalk or paint pen ....................................................... 1

Socket, 7/16", 3/8" drive .............................................. 1

Ratchet, 3/8" drive ....................................................... 1

Internal snap ring pliers ............................................... 1

Using an insulated wrench, disconnect the negative (-)

battery cable from the battery (Ref. Fig. 1 on Page G-1).

Remove all wires from motor.

Fig. 1 Disconnect Battery Cable

Mark both the axle and motor housings to permit realign-

ment during reassembly of motor to rear axle (Ref. Fig.

2 on Page G-1).

Fig. 2 Mark Axle and Motor

On TCT motors, remove the snap ring and remove the

speed sensor from the motor end cover.

Take care not to damage the splines when removing

and reassembling the motor to the rear axle housing.

Remove the three bolts that secure the motor to the axle

housing and carefully slide the motor straight out from

the axle splines.

Motor Disassembly

Tool List

Qty. Required

Straight blade screwdriver ...........................................1

Ratchet, 3/8" drive .......................................................1

Socket, 3/8", 3/8" drive ................................................1

Plastic faced hammer ..................................................1

Remove BL-

Front of Vehicle