European Safety Systems Ltd.

Impress House, Mansell Road, Acton, London W3 7QH

www.e2s.com Tel: +44 (0)208 743 8880

Document D154-00-151-IS Issue 8 12-09-2022

Sheet 2 of 3

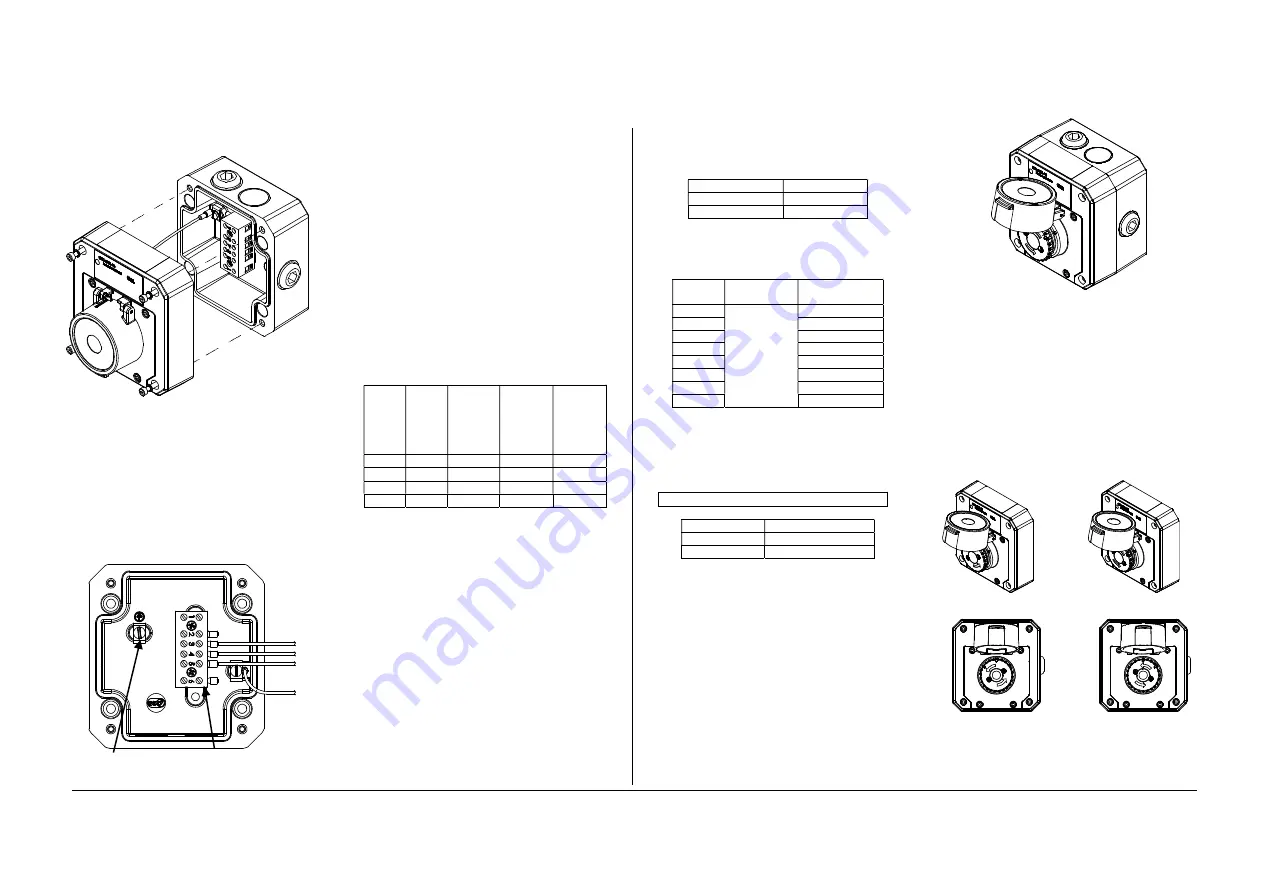

This is achieved by removing the 4 off M4 cap

head bolts holding on the cover.

Once the screws are removed the cover will hang

down out of the way to gain access to the Ex e

terminal block, the internal earth terminal and

mounting hole recesses.

6)

Earthing

The unit has an internal earth terminal.

It is recommended that a cable crimp lug is used

on the earth wires.

The internal earth wire is placed under an earth

clamp which will stop the cable twisting. This is

secured by an M4 screw and spring washer.

Internal Earth

Ex e terminal block

terminal

Note: Depending on options chosen an 8-Way DIN

Rail or 6-Way terminal block may be selected.

7)

Cable connections

There are 3 off cable entries for M20x1.5 Ex e

approved cable glands or stopping plugs with a

minimum ingress protection of IP66

The unit can be wired in a number of different ways

depending on the device combination selected.

EOL (End of line) device;

resistor – ExxxR / diode – ED1 / zener – ExxxZ

Series (In line) device;

resistor – SxxxR / diode – SD1 / zener – SxxxZ /

LED

Microswitch 1 = M/S 1

Microswitch 2 = M/S 2

The unit can be wired with a maximum of 2 module

devices – refer to wiring schematic D154-06-051

Voltage

option

Max

Voltage

Min

resistor

value

allowable

in module

Type B

unit

(2.0W)

Min

resistor

value

allowable

in module

Type D

unit

(1.0W)

Min

resistor

value

allowable

in module

Type E

unit

(1.75W)

6 V dc

9 V dc

47 ohms

91 ohms

51 ohms

12V dc

15 V dc

120 ohms

240 ohms

150 ohms

24V dc

28 V dc

470 ohms

820 ohms

510 ohms

48V dc

56 V dc

1K8 ohms

3K3 ohms

2K0 ohms

When wiring to Increased Safety terminal

enclosures, you are only permitted to connect one

wire into each way on the terminal block unless a

pair of wires are crimped into a suitable ferrule.

For the six-way terminal block wire sizes allowable

are 0.5mm² to 4.0mm². For the 8-way DIN rail wire

sizes allowable are 0.5mm² to 2.5mm².

Leads connected to the terminals shall be insulated

for the appropriate voltage and this insulation shall

extend to within 1mm of the metal of the terminal

throat. They shall only be installed and wired with

cable in an ambient temperature of -10°C to +80°C

All terminal screws, used or unused, shall be

tightened down to between 0.5 Nm and 0.7 Nm

7.1) Fitted LED, Diode or Zener Diode

If a diode module is pre-fitted as either an EOL or

series device, the following current limitation

applies:

Unit Voltage

Max. Current

48V DC

0.75A

6, 12 & 24V DC

2.0A

If a Zener diode module is pre-fitted as either EOL

or Series device, the following current limitation

applies:

Zener

Voltage

Max. Input

Voltage

Max. Current

3.3V

56V DC

230mA

4.7V

162mA

5.1V

149mA

5.6V

136mA

6.2V

122mA

6.8V

112mA

10V

76mA

12V

63mA

If an LED indicator is pre-fitted (optional on

GNExCP6B Units only), the LED is protected by

the LED current-limiting resistor. See value of this

resistor in table below. This only applies to units

with LED option code ‘L’.

GNExCP6B-PBXXXXXXXXX

L

-XX-ExxxR-SxxxR

LED Resistor

Max. Input Voltage

3K3 (3300Ω)

56V DC

1K5 (1500Ω)

28V DC

In any scenario, the lowest value of maximum

current should be used. For example, if the unit has

both a diode and a Zener diode, the Zener diode

would determine the maximum input current of the

unit, since its max. current is lowest.

8)

Testing unit operation

The push button unit can be tested without the

need to replace any element.

To test, lift the cover lift flap to reveal the push

button. The button should be pressed into the body

to activate the unit and place it into the operated

condition.

The call point switch will now change over its

contacts to operate the alarm.

Once testing is complete the unit needs to be reset

from the operated condition.

Rotate the push button anticlockwise by an angle

of 55°, see guide alignment marks on the button

and cover, shown below (1). The push button

should pop back up to its original position.

Ensure that the push button has also twisted back

clockwise by 55° to its original position see guide

marks on button and cover, shown below (2). The

unit is now reset

1. On operated unit

2. Button should pop

twist push button

up and twist back to

anticlockwise 55°

original position

to reset