_______________________________________________________________________________________________________________________________

European Safety Systems Ltd.

Impress House, Mansell Road, Acton, London W3 7QH sales@e2s.com Tel: +44 (0)20 8743 8880

www.e2s.com Fax: +44 (0)20 8740 4200

Document No. IS 4601 Issue G 13-01-20

Sheet 2 of 6

Areas. When designing systems for installation outside the

UK, the local Code of Practice should be consulted.

1) The certification marking is as follows:

e

2S

european safety systems ltd.

London W3 7QH UK

www.e2s.com

WARNING:

TO AVOID A POSSIBLE ELECTROSTATIC

CHARGE ONLY CLEAN WITH A DAMP CLOTH

IS-L101L Beacon

II 1G

2813

SIRA 04ATEX2302X

Year / Serial No. 09 / 1000001

IECEx SIR 04.0039X

Ui = 28V Ii = 660mA Pi = 1.2W

Ci = 0 Li = 0

Ex ia IIC T4 Ga (-40ºC <=Ta<= +60°C)

2) The equipment may be used in zones 0, 1 and 2

with flammable gases and vapours with apparatus

groups IIA, IIB & IIC and with temperature classes

T1, T2, T3 and T4.

3) The equipment is only certified for use in ambient

temperatures in the range -40

o

C to +60

o

C and

should not be used outside this range.

4) The certificate number has an ‘X’ suffix, which

indicates that the certificate contains one of more

special conditions for safe use. Those installing or

inspecting the equipment should refer to this section

of the certificate.

5) The equipment has not been assessed as a safety-

related device (as referred to by Directive 94/9/EC

Annex II, clause 1.5).

6) Installation of this equipment shall be carried out by

suitably-trained personnel in accordance with the

applicable code of practice.

7) Repair of this equipment shall only be carried out by

the manufacturer or in accordance with the

applicable code of practice.

8) The certification of this equipment relies on the

following materials used in its construction:

Enclosure:

ABS Plastic

Lens:

Polycarbonate

If the equipment is likely to come into contact with

aggressive substances, then it is the responsibility of

the user to take suitable precautions that prevent it

from being adversely affected, thus ensuring that the

type of protection is not compromised.

“Aggressive substances” - e.g. acidic liquids or

gases that may attack metals, or solvents that may

affect polymeric materials.

“Suitable precautions” - e.g. regular checks as part

of routine inspections or establishing from the

material’s data sheet that it is resistant to specific

chemicals.

SPECIAL CONDITIONS FOR SAFE USE (as stated on the

IS-L101L EC Type Examination Certificate SIRA

04ATEX2302X)

The enclosure is non-conducting and may generate an

ignition-capable level of electrosatic charges under certain

extreme conditions. The user should ensure that the

equipment is not installed in a location where it may be

subjected to external conditions that might cause a build-

up of electrostatic charges on non-conducting surfaces,

additionally, cleaning of the equipment should be done

only with a damp cloth.

The equipment has an ingress protection rating of IP 66.

However, if it has been supplied without cable entry devices,

then the user shall ensure that the devices that are fitted will

provide an ingress protection that is appropriate to the

environment in which it is installed i.e. IP20 or better. If only

one of the two cable entries are used, then the unused entry

shall be fitted with a blanking device that ensures ingress

protection appropriate to the environment in which it is

installed i.e. IP20 or better.

SPECIAL CONDITIONS FOR SAFE USE (as stated on the

IS-A105N sounder EC Type Examination Certificate SIRA

04ATEX2301X)

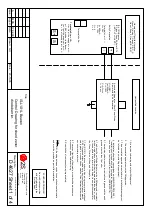

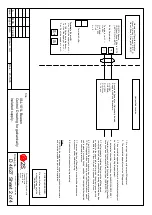

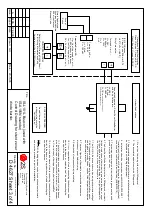

The equipment shall only be supplied via Terminals + w.r.t.

Terminals - from a barrier having a maximum open circuit

voltage Uo that is < 28 V and a maximum short circuit current

Io that is < 93 mA, where Io is resistively limited. The barrier

shall be ATEX certified by a notified body.

The total capacitance connected to ter wrt – (i.e. the

capacitance of the cable plus any other capacitance) shall

not exceed 83nF.

4.2 Zones, Gas Groups and T Rating

The IS-L101L beacon has been certified Ex ia IIC T4 Ga.

When connected to an approved system it may be installed

in:

Zone 0

explosive gas air mixture

continuously present.

Zone 1

explosive gas air mixture likely to occur in

normal operation.

Zone 2

explosive gas air mixture not likely to occur,

and if it does, it will only exist for a short time.

Be used with gases in groups:

Group

A

propane

Group

B

ethylene

Group

C

hydrogen

Having a temperature classification of:

T1

450ºC

T2

300ºC

T3

200ºC

T4

135ºC

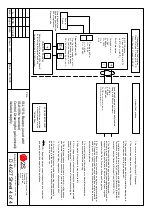

4.3 Ter and - power supply

Power is supplied to the beacon via ter and - which

have maximum input safety parameters of:

Ui

=

28V

Ii

=

660mA

Pi

=

1.2W

Ci = 0

Li = 0

IS-L101L beacons may be powered from ATEX certified

Zener barriers or galvanic isolators certified by an EC

Approved Body with output parameter equal to or less than

28V and 1.2W.

Up to three IS-L101L-IS beacons can be connected in

parallel and be powered from a common barrier or isolator.

Parallel connection of beacons will significantly reduce the