KO-II

MANUAL

4

www.

eaeelectric

.com

www.

eaeelectric

.com

General

N

N

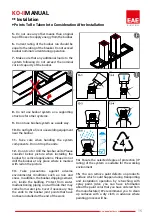

BUSBARS SHOULD

NOT BE IN TOUCH WITH

ANY LIQUID MATERIAL

Dry

Envoirement

Rain

Drops

Please use canopy

for outdoor

applications.

Please use porch

for outdoor.

Please use porch

for outdoor.

Please use canopy

for building expension

points.

Chemicals

Urine

Water

CLOSE

INDIRECT or DIRECT

WATERWAYS

BUSBARS THAT ARE NOT

ASSEMBLED COMPLETELY

HAVE NO PROTECTION

AGAINST TO WATER

Summary of Contents for E-Lineko-II

Page 1: ...E LINEKO II MANUAL www eaeelectric com ...

Page 2: ...E LINEKO II ...