Installation, Operation and Parts Manual

EE-6215EKZ

19

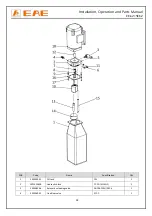

Step

10:

Install

lifting

arms.

Connect

the

lifting

arm

and

the

carriage.

The

arm

pin

shafts

(No.

2)

must

be

greased

at

the

installation

Install

the

lifting

arms

onto

the

carriages

and

ensure

the

arm

lock

could

work.

Attention:

Install

Lifting

arms

and

fix

feet

protection

bars

ONLY

after

the

complete

assembly

has

been

erected

and

anchored.

Step

11:

Fill

with

hydraulic

oil.

CLEAN

AND

FRESH

OIL

ONLY.

DON’T

FILL

THE

TANK

COMPLETELY

FULL.

Lift

must

be

fully

lowered

before

changing

or

adding

hydraulic

oil.

Prepare

13

liters

of

hydraulic

oil.

Firstly,

fill

about

10

liters

into

the

oil

tank

and

run

the

lift

up

and

down

for

2

or

3

times.

After

running

the

lift

for

several

cycles,

add

more

oil

if

necessary

to

raise

lift

to

full

height.

Note

:

It

is

suggested

to

use

NO.46

hydraulic

oil

when

average

temperature

of

the

location

is

above

18

degree

Celsius

and

using

NO.32

hydraulic

oil

when

temperature

is

below

18

degree

Celsius.

Change

the

oil

6

months

after

initial

use

and

change

once

per

year

thereafter.

Step

12:

Trial

running.

Get

familiar

with

lift

controls

by

running

the

lift

through

a

few

cycles

before

loading

vehicle

on

lift.

This

step

is

of

particular

importance

for

it

can

check

if

the

oil

hoses

are

well

connected.

The

connection

is

qualified

when

there

is

no

abnormal

sound

or

leakage

after

having

been

tested

for

5

‐

6

times.

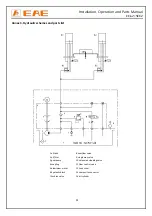

Bleeding

the

hydraulic

system

Unscrew

but

don't

remove

the

nut

on

top

of

the

oil

cylinder

and

slightly

press

the

UP

button

until

oil

gets

out.

Screw

the

nut

tight

thereafter.

After

bleeding,

oil

level

in

power

unit

reservoir

may

be

down.

Raise

and

lower

lift

several

cycles.

Add

more

oil

if

necessary

to

raise

lift

to

full

height.

It

is

only

necessary

to

add

oil

to

raise

lift

to

full

height.

Check

the

mechanical

safety

locking

unit.

Check

if

its

safety

locking

plates

can

be

effectively

engaged

or

released

in

the

running

process.

Check

the

synchronization

of

both

lifting

carriages.

Ensure

the

synchronization

by

adjusting

the

balance

steel

cables

at

both

sides.

Make

both

cables

be

of

the

same

tightness.

This

could

be

judged

by

the

sound

emitted

by

the

safety

locking

unit

during

lifting

process.

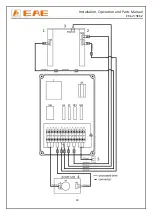

If

the

lift

doesn't

raise,

the

motor

may

turn

in

the

wrong

direction.

In

such

event,

interchange

wires

U,

V

in

the

connection

box.

1.Carriage

2.Arm

pin

shaft

3.Arm

4.Handle

of

arm

lock

5.Arm

lock

unit

Vent

air

remained

in

the

cylinder