4810 Clover Road • Greensboro, NC 27450 • 1-800-336-2776 • www.eagleequip.com • © Eagle Equipment 2018.01 • page 10

POSITION AND INSTALLATION

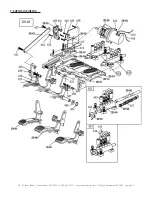

PARTS OF THE BALANCER

1. Rotation Pedal

2. Rise-fall Pedal

3. Bead Breaker Pedal

4. Bead breaker buffer

5. Bead Breaker shovel

6. Auxiliary rotating rod

7. Column

8. Demount/mount head

9. Tire pressing roller

10. Raise-fall control valve

1. Unscrew the nuts at the bottom, position the machine and

calibrate it with the horizontal rule. Mount the machine with

all the screws and to ensure the machine is stable. Make sure

the system is equipped with a good grounding circuit for

prevent electric leakage and have operation range of ground

for skid prevention.

2. Unscrew the nut A on the machine body B as shown in Figure 4. Lift the column C; mount it on the

machine body B by using the nut A through the bolt located on the machine body B. If the column

becomes loose, tighten it immediately. Otherwise this may damage the tire.

3. Attach the tire lifting device on the side of machine body with bolt set A, shown as Figure 5; after

fixing all the bolts, connect the air hose B&C.

4. Attach the left assist arm on the post and cabinet with 10pcs M10 bolts. Put the 8MM pipe into the

cabinet from the right reservation hole (2) of the machine and plug on the three-way connection,

as shown in Figure 6.

5. Attach the cylinder T1 on the swing arm with 2 bolts T2. Attach the tire pressing roller on the

piston rod and tighten with the hex screws T3. Make sure that the tire pressing roller can rotate

freely; connecting the air hose (Figure 7).

Figure 3

Figure 7

Figure 6

Figure 5

Figure 4

11. Vertical arm

12. Adjust handle

13. Inflating gun

14. Quick release nut

15. Cone

16. Rubber protection washer

17. Tire installation base assembly

18. Tire lifting device

19. Tire lifting support