Eagle Solutions, ©2008, Tracker Operator Manual Page #16

Eagle Solutions, ©2008, Tracker Operator Manual Page #17

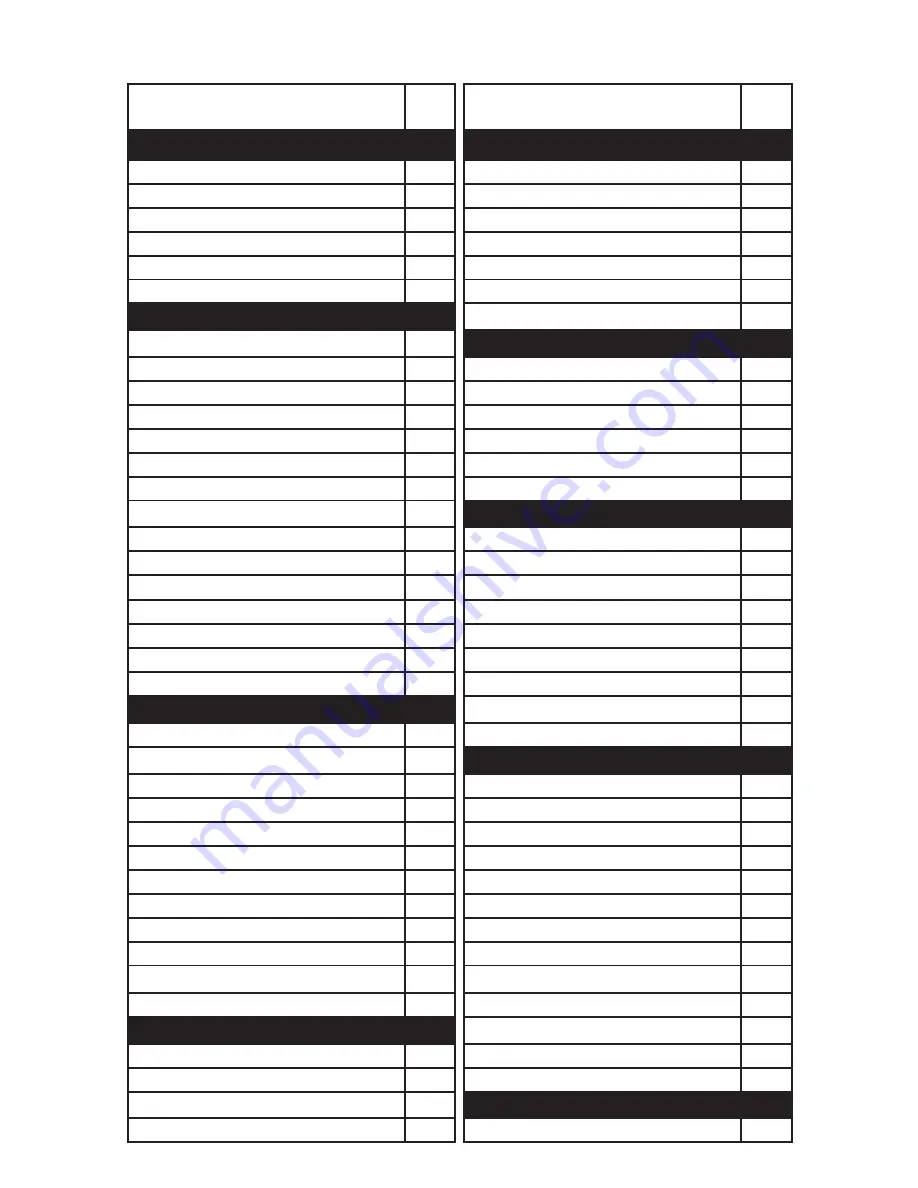

Job Description

Labor

Hours

Allowed

Job Description

Labor

Hours

Allowed

TUNE UP & ADJUSTMENT

PISTON & CRANKSHAFT

COMPRESSION MEASUREMENT (ALL)

0.4

PISTON OR RING SET (1 CYCL)

2.1

VALVE CLEARANCE ADJUSTMENT (ALL)

0.6

PISTON OR RING SETS (ALL)

2.9

VALVE CLEARANCE ADJUSTMENT (1 CYL)

0.3

CRANKSHAFT

3.3

GOVERNOR ADJ

(Includes low idle & high speed adj) (ALL)

0.3

CONNECTING ROD (1CYL)

2.1

LOW IDLE & HIGH SPEED ADJUSTMENT (ALL)

0.2

CONNECTING RODS (ALL)

2.9

CARB CLEANING (ALL)

0.7

CRANK/OR CAMSHAFT OIL SEAL (PTO SIDE)

0.9

CYLINDER HEADS, VALVES & CAMSHAFT

CRANK/CAMSHAFT OIL SEAL

(FLYWHEEL SIDE)

0.8

CYLINDER HEAD COVER OR GASKET (1 CYL)

0.2

RECOIL STARTER & GOVERNOR

CYLINDER HEAD COVERS OR GASKETS (ALL)

0.3

RECOIL STARTER ASSY

0.1

CYLINDER HEAD (1 CYL)

1.7

REEL, SPRING OR ROPE

0.3

CYLINDER HEADS (ALL)

2.2

GOVERNOR ASSY OR SLEEVE

1

CYLINDER HEAD GASKET (1 CYL)

1.3

GOVERNOR SHAFT OR OIL SEAL

0.9

CYLINDER HEAD GASKETS (ALL)

1.8

GOVERNOR ARM

0.3

VALVE AND/OR SPRING (1 VALVE OR SPRING)

1.5

CONTROL PANEL ASSY

0.3

VALVE AND/OR SPRINGS

(2 VALVES OR SPRINGS) (1 CYL)

1.6

CARB, FUEL PUMP AND FUEL TANK

VALVES AND/OR SPRINGS (ALL)

2.2

CARBURETOR

0.5

VALVE LAPPING OR VALVE GUIDE

(1 VALVE, 1 CYL)

1.6

CARB HOLDER OR INTAKE MANIFOLD

0.6

VALVE LAPPING (2 VALVES, 1 CYL)

1.8

CHOKE VALVE(S)/THROTTLE VALVE(S)

(INCLUDES

CARB R&R)

0.6

VALVE LAPPING OR VALVE GUIDES (ALL)

2.6

MAIN JET(S) FLOAT OR VALVE

(INCLUDES CARB R&R)

0.6

CAMSHAFT

1.3

FLOAT CHAMBER GASKET

0.3

ROCKER ARM OR PUSH ROD (1 ARM OR ROD)

0.4

SOLENOID VALVE OR FUEL CUT VALVE

0.3

ROCKER ARMS OR PUSH RODS (ALL)

0.6

FUEL TUBE (TO CARB)

0.2

CYLINDER/CRANKCASE & OIL PUMP

DIAPHRAGM FUEL PUMP

0.2

CYLINDER BORING & HONING (1 CYL)

4.8

FUEL FILTER

0.1

CYLINDER BORING & HONING (ALL)

5.3

IGNITION, COOLING & STARTER MOTOR

CRANKCASE OR MAIN BALL BEARINGS

4.1

ENGINE FLYWHEEL

0.7

BREATHER, BREATHER COVER OR REED VALVES

1

CHARGING COIL OR STARTER

0.9

CRANKCASE COVER

1.2

IGNITION COIL (1)

0.5

CRANKCASE COVER GASKET

0.8

IGNITION COILS (ALL)

0.7

OIL FILTER (CARTRIDGE) OR OIL DRAIN PLUG

0.1

SPARK PLUG (1)

0.1

OIL PUMP

1.1

SPARK PLUGS (ALL)

0.2

OIL PRESSURE RELIEF VALVE

1

VOLTAGE REGULATOR

(REGULATOR/RECTIFIER)

0.2

OIL FILTER SCREEN (INTERNAL)

0.9

COOLING FAN

0.3

OIL DRAIN PLUG OR GASKET, OR OIL FILTER/

OIL LEVEL DIPSTICK TUBE

0.1

COOLING FAN HOUSING

0.2

OIL PRESSURE SWITCH

0.2

UPPER ENGINE SHROUD

0.2

AIR CLEANER/MUFFLER

LOWER ENGINE SHROUD

0.2

AIR CLEANER CASE

0.2

STARTER MOTOR ASSY

0.3

AIR CLEANER ELEMENT OR COVER

0.1

STARTER BRUSH(ES)

(INCLUDES STARTER (R&R))

0.5

MUFFLER OR HEAT COVERS

0.2

MISC

EXHAUST PIPE(S) OR GASKET(S)

0.3

DIAGNOSIS

0.5

Engine Warranty Flat Rate Chart

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com