4810 Clover Road • Greensboro, NC 27450 • 1-800-336-2776 • www.eagleequip.com • © Eagle Equipment 2017.12 • page 22

11. IMBALANCE OPTIMIZATION

If the wheel imbalance value is over 30 grams (1 ounce), the system will display “OPT”.

There are two methods for imbalance optimization:

11.1 THE DISPLAY SHOWS THE BALANCE VALUE

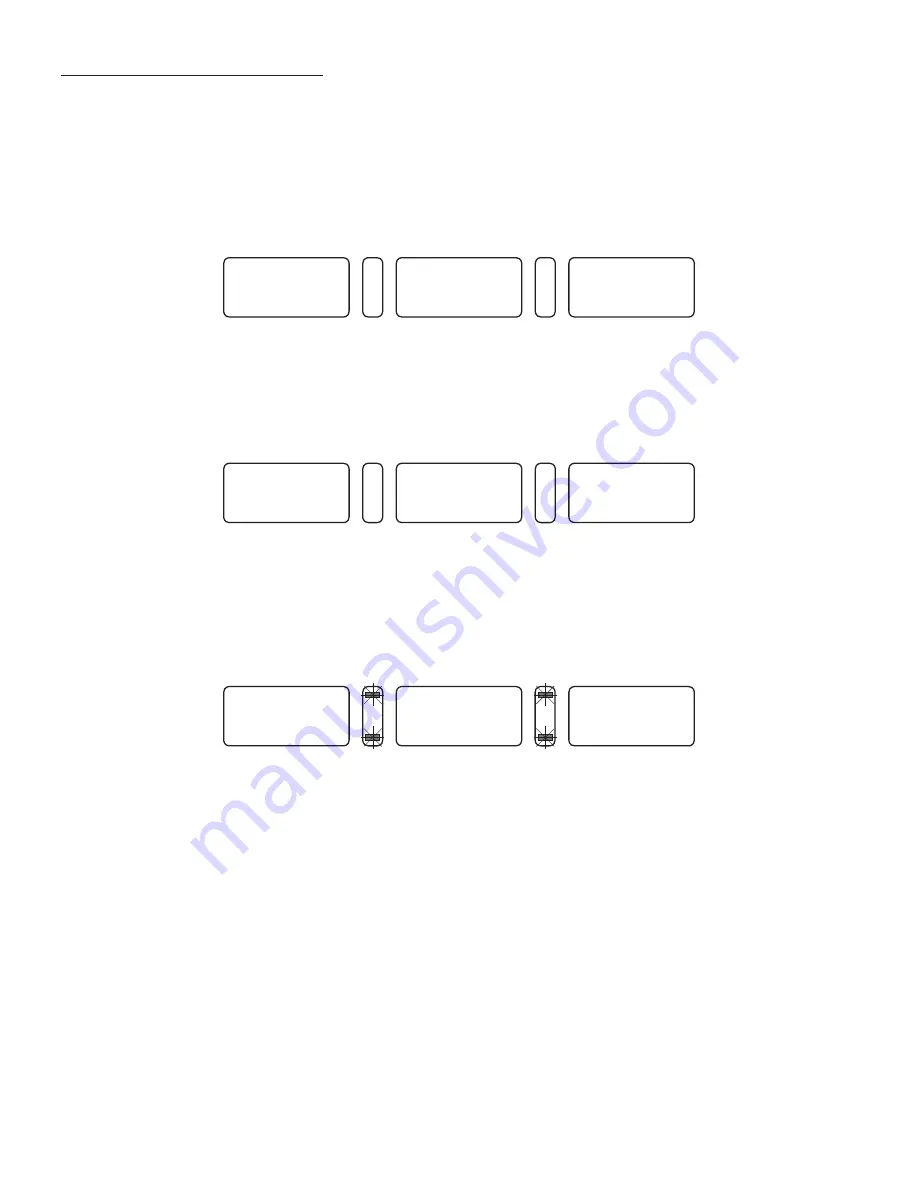

If you have already finished the balance test, you will need to process imbalance optimization. Press

the OPT key. The display will show (Figure 11-1).

Use a chalk mark to make a reference point on the flange plane and rim and tire. Use the tire changer to

exchange the rim and tire 180°. Reinstall the wheel on the balancer and make sure to mark the reference

point between the flange plane and rim in the same position. Press START key, display (Figure 11-2).

(Figure 11-2) The left LED display is a percent of optimization, if before optimize static value is 40

gram (1.5 ounce), optimization is 85%. After optimization, only 6 gram should remain of the static

value (15%×40gram=6gram). Slowly spin the wheel by hand. When both sides of the two position

indicator lights are flashing (Figure 11-3), use a chalk mark or pen to make a mark on the tire.

Remove the wheel from the balancer, use tire changer to remove the tire from the rim. Make tire and

rim marks together. Use the tire changer to fit the tire on the rim. Optimization is complete.

11.2 PROCESS IMBALANCE OPTIMIZATION DIRECTLY

Before turning the power on, process the imbalance optimization directly. Turn on the power, install

the wheel, press OPT key. The left side will display OPT, press START key, display will show (Figure 11-1).

Follow 11.1 section to operation. Press STOP key to stop operation.

OOO

180

Figure 11-1

852

40

Figure 11-2

852

40

Figure 11-3