- 9 -

5. Maintenance and Troubleshooting

TURN OFF MACHINE AND DISCONNECT IT FROM THE POWER

SOURCE PRIOR TO PERFORMING ANY MAINTENANCE OR SERVICE

5.1 Regular Maintenance & Cleaning

1. Check all bolts and screws regularly to ensure smooth, malfunction-free operation of the

machine.

2. Lubricate moving parts of the machine on a regular basis.

3. Clean the machine surfaces.

4. Clean off any tape residue from the cutting blade daily.

5. If the machine is to be stored for an extended period of time, the cutting blade should be oiled

prior to being placed in storage.

5.2 Lubrication

1. The driving chain should be lubricated once a month.

2. The bearings should be lubricated once a month.

3. The transmission axle, driving chain and bearing should be lubricated once a week.

4. All other moving parts should be lubricated on a regular basis.

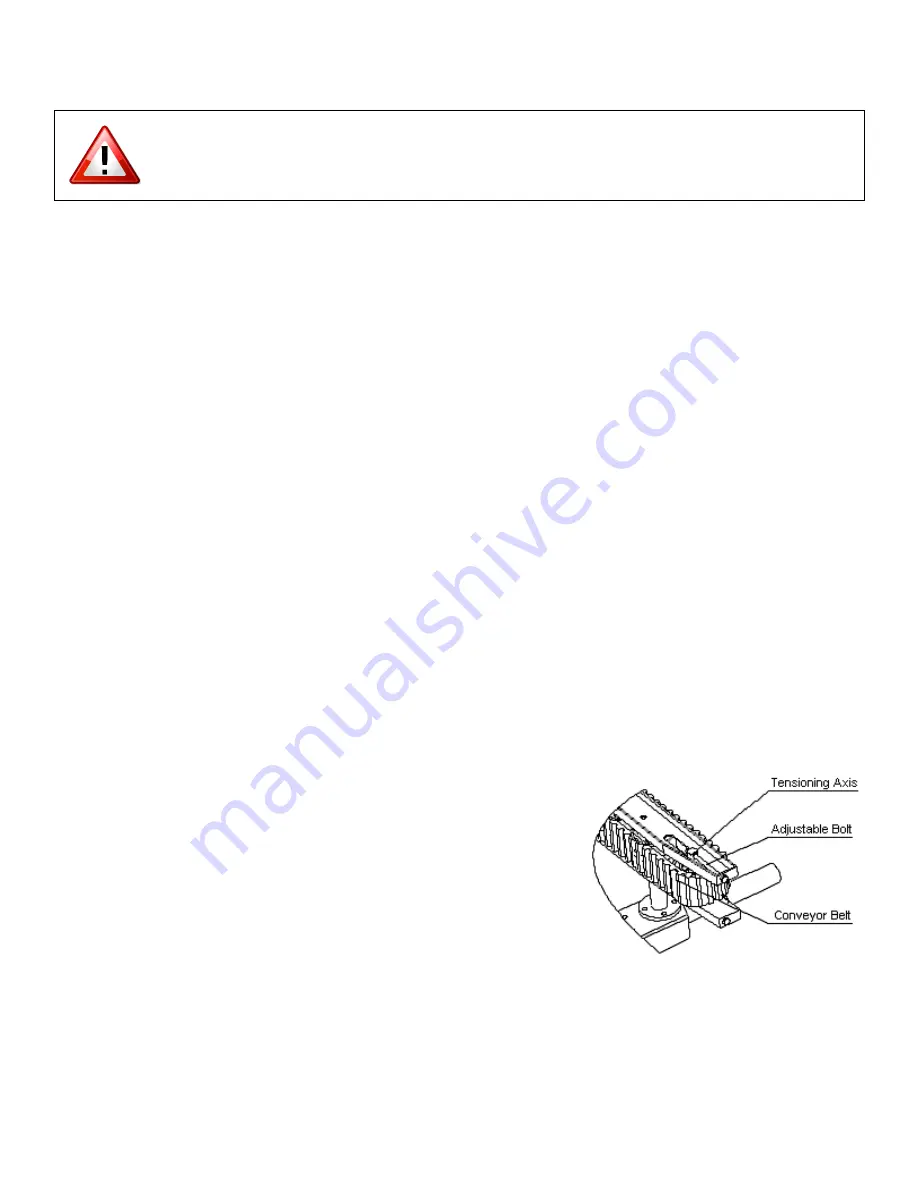

5.3 Conveyor Belt Adjustment

Adjustments are made using the adjustable bolt located at the

end of the side conveyer system.

Summary of Contents for T100

Page 16: ...16 6 Illustrations Parts List 6 5 Side Conveyor System...

Page 26: ...7 Electrical Schematics 26...

Page 27: ...27 7 Electrical Schematics...

Page 28: ...28 7 Electrical Schematics...