41

Earthcore Industries

08/2017

BVETTO B-Vent Gas Fireplace

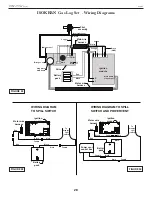

ECODAMPER System - Wiring Diagram

MECHANICAL DRAFT SYSTEM FOR A GAS-

FIRED FIREPLACE WITH DAMPER AND

SAFETY SYSTEM PER NFPA 54/IFGC

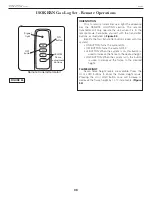

APPLICATION

This installation shows a combination fireplace and

damper system. The ADC100 control monitors fan and

damper operation and the safety system. No adjust-

ments are necessary after the system is installed and

commissioned. The ADC100 does not have to be vis-

ible and can be installed in the attic.

Proven Draft Switch is part of ADC100 control.

SEQUENCE OF OPERATION

1. During commissioning, the fan speed is set using

the potentiometer located on the ADC100

control board.

2. When the gas igniter is activated, the fan speed

increases and the damper begins to open. Once

the damper is fully open and the proven draft

switch closes, the fan returns to the speed setting

of the potentiometer and the ADC100 releases

the gas valve.

3. If proper draft is not maintained, the ADC100 will

increase fan speed gradually until the PDS closes.

If the PDS has not closed 10 seconds after the

fan reaches 100% speed, the ADC100 will shut

off the gas valve and go into alarm mode. If

the PDS closes while in alarm mode, the fan will

resume the original speed setting.

4. Once the fireplace is turned off, the fan will

continue to operate for a set post-purge time

(adjustable between 0-10 minutes) to remove any

remaining products of combustion before shutting

down. The damper closes 10 seconds after the

fan is shut off.

5. In case of a mechanical or electrical failure the

ADC100 will shut off the gas valve.

RED

ORANGE

WHIT

E

BLAC

K

GREEN

FAN

MOTOR

120/1/60

NOTES:

THE DISCONNECT MEANS AND CIRCUIT PROTECTION ARE TO

BE PROVIDED BY THE INSTALLER OF THIS DEVICE

1

All wiring must be in

flexible or rigid metal

conduit

LEGEND:

24 VAC

120 VAC

N

L

FAN CONTROL UNIT

7 8 9 10 1

1 12 13 14 15 16 17 18 19

1 2 3 4 5 6

WEATHERPROOF BOX

MAIN CONTROL UNI

T

6 5 4 3 2 1

All wiring must be in

metal conduit or

shielded cable

Note:

The diagram is for

reference only. Job specific

wiring diagrams can be

provided by ENERVEX.

FIGURE 58