7

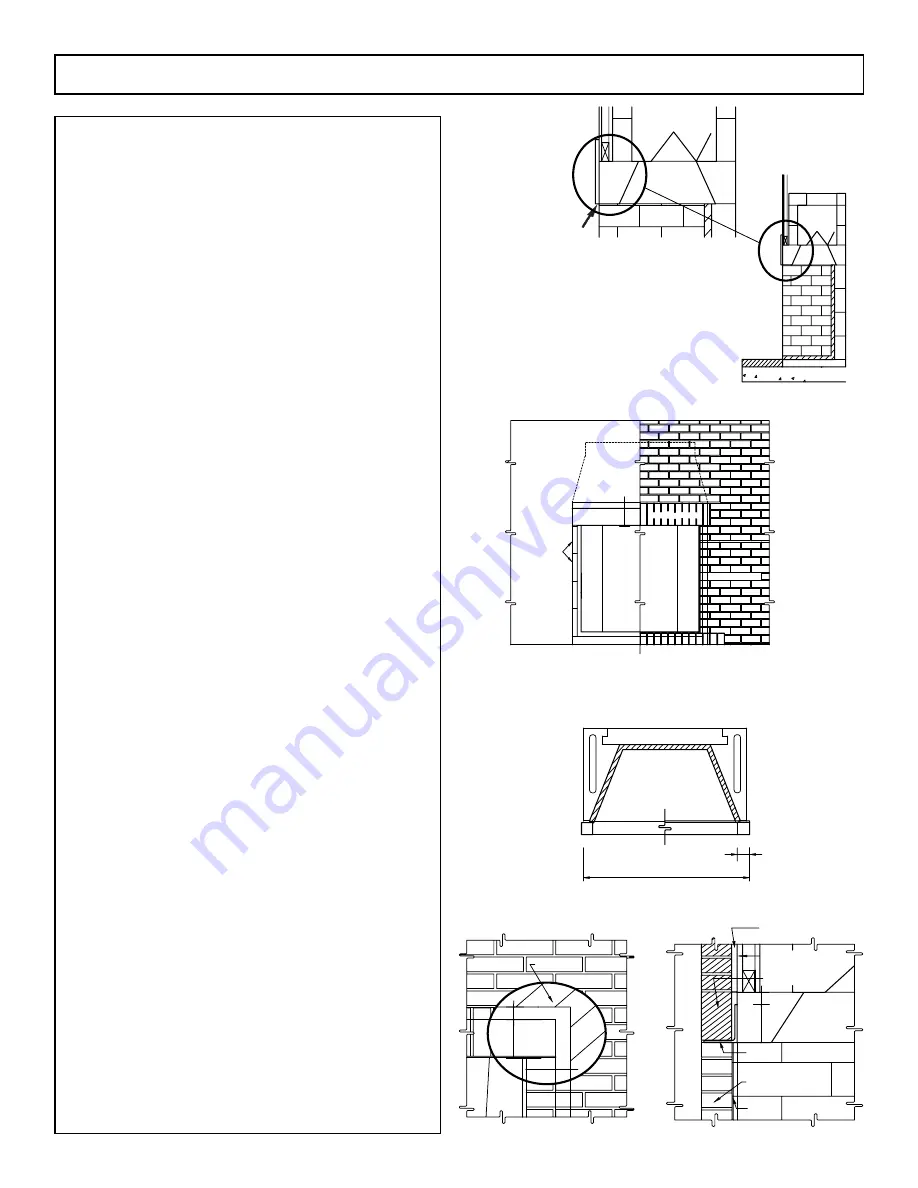

Cladding

The material that makes up the Isokern fireplaces

has a porous surface which allows most facing material to

be applied directly to the Isokern firebox without additional

framing. It is recommended that when applying veneers to

the Isokern material directly, it is best to attach lathe to the

firebox, scratch coat and apply plaster, brick, stone or stucco

as the finish.

When facing material is installed directly to the

surface of the Isokern fireplace unit, be sure that when

the required noncombustible finished facing materials are

applied that no gaps or voids are left. This would create a

“false chimney” which must be avoided. Completely seal

all gaps and voids in the noncombustible finished facing

materials directly to the Isokern unit with Earthcore mortar

or other noncombustible grout.

Brick, stone or other masonry veneer finished

fronts to Outdoor fireplaces are possible. Special attention is

required with regards to:

(1) the placement of the proposed masonry veneer facing and

its interface with the Outdoor fire brick lining, and

(2) Clearance to combustible framing (if any) and sheathing

from any steel “L” support used in the masonry veneer around

the front of the unit behind the veneer facing.

Any proposed brick, stone or other masonry veneer

facing must have sufficient foundation to support the full

weight of the veneer work. This may require review by a

local structural engineer prior to construction.

The veneer facing, when installed, must present a tight seal

with the leading edge of the fire brick lining at the sides of

the firebox opening. A steel “L” will need to span the top of

the finished fireplace opening to carry the masonry veneer as

it spans over the firebox opening.

By code requirement this steel “L” must have a minimum

four inch (4”) end bearing. This bearing surface area shall be

provided in the veneer work. It is important that the steel “L”

is set tight against the damper beam front and set in a mud

joint to avoid creating a “false chimney” between the back of

the steel “L” and the damper beam front.

Avoid “False Chimneys”

Seal all gaps completely.

4

"

2"

6"

BEARING

4x6 STEEL L

ISOKERN UNIT WIDTH DIM'N.

EXTENT OF STEEL L

MIN.

4x6 STEEL L

MASONRY VENEER

ENDS OF ISOKERN

STEEL L ALIGN

FIREBOX UNIT AND

2"

6"

4"

2"

BEARING

2"

6"

WOOD (FLAMMABLE)

SHEATHING

MIN. CLEARANCE

MIN. CLEARANCE

BRICK

VENEER

WOOD (FLAMMABLE)

SHEATHING

MASONRY VENEER

4x6 STEEL L

MASONRY BEYOND

AIR SPACE

MORTAR JOINT

MASONRY VENEER

IF APPLICABLE