SV-407-KIT (01/12)

Page 4

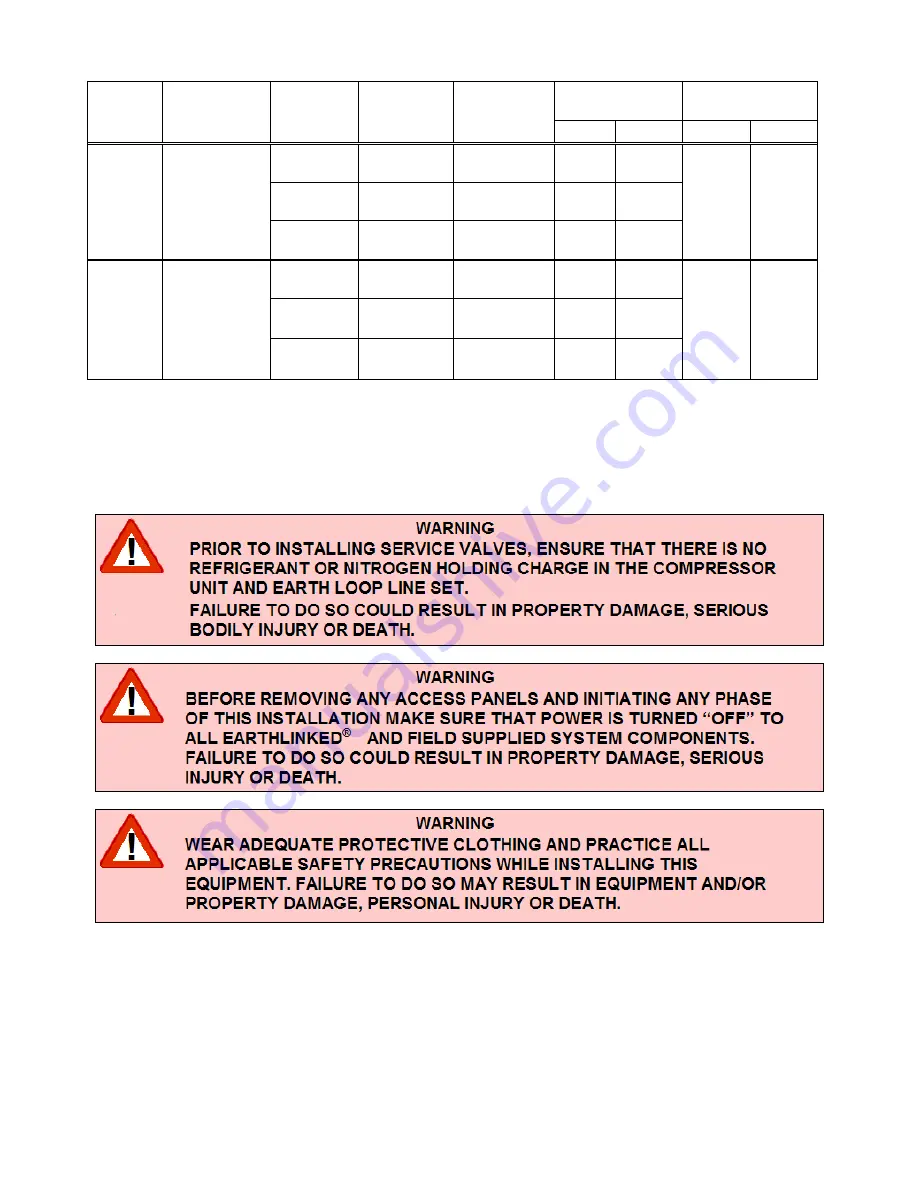

COMP.

UNIT

SIZE

SVC. VALVE

KIT MODEL

COMPR

UNIT

SERIES

ADAPTER

KIT

MODEL

ADAPTER

SIZES*

SVC. VALVE

SIZES*

LINE SET

SIZES*

LIQUID

VAPOR

LIQUID

VAPOR

-060

SV-4260

SC, SD

SCW, SW

AKS-60

1/2 x 1/2

1-1/8 x 7/8

1/2

7/8

1/2

1-1/8

HC, HCW

AKHC-60

1/2 x 1/2

7/8 x 7/8

1/2

7/8

HW, HWW

AKHW-60

1/2 x 1/2

1-1/8 x 7/8

1/2

7/8

-072

SV-7200

SC, SD

SCW, SW

AKS-72

1/2 x 1/2

1-1/8 x 7/8

1/2

7/8

1/2

1-1/8

HC, HCW

AKHC-72

1/2 x 1/2

1-1/8 x 7/8

1/2

1-1/8

HW, HWW

AKHW-72

1/2 x 1/2

1-1/8 x 7/8

1/2

1-1/8

*All sizes are inches, OD.

CONTINUED FROM PREVIOUS PAGE

Figure 1. Service Valve/Compressor Unit/Line Set Match, continued

Service valves are installed on the EarthLinked

®

heating and cooling system earth loop line set near

the compressor unit, to enhance serviceability of the compressor unit and earth loops.