Operator's Manual

CRT Models 5040 and 6040E

Check for parts online at

www.getearthquake.com

or call 800-345-6007 M-F 8-5 CST

15

SERViCinG thE RototiLLER

The following information will help you make the

necessary checks and perform the procedures required

to follow the normal care recommendations made for

your rototiller unit.

If you prefer, your local authorized dealer can make these

checks and perform the required procedures for you.

mAintEnAnCE

mAintEnAnCE SChEduLE

Your rototiller has been designed and produced by the industry’s leading manufacturer of outdoor power equipment

to provide you with years of reliable operation.

Keeping your tiller in top running condition will prolong its life, and help you obtain optimum performance.

Please read this normal care schedule, and note the recommended care operating intervals to extend the life of your unit.

maintenance operation

Page

Before

Each use

50 hours or

Every Season

Change forward/reverse belt

16

x

Engine maintenance

17

x

x

Check or fill engine crankcase with oil

17,EM

x

2

Check tiller transmission grease

17

x

Check tire pressure

17

x

Lubrication

18

x

Clean tine axle shaft

18

x

Storage

18

x

Check throttle control adjustment

EM

1

Em

= See engine manual

1

Adjust throttle control after first 3 hours of operation or if engine is hard to start or run-on occurs.

2

Change oil after first 5-8 hours of use, then after every 50 hours or every season. Change oil every 5

hours when operating under heavy load or in high temperatures.

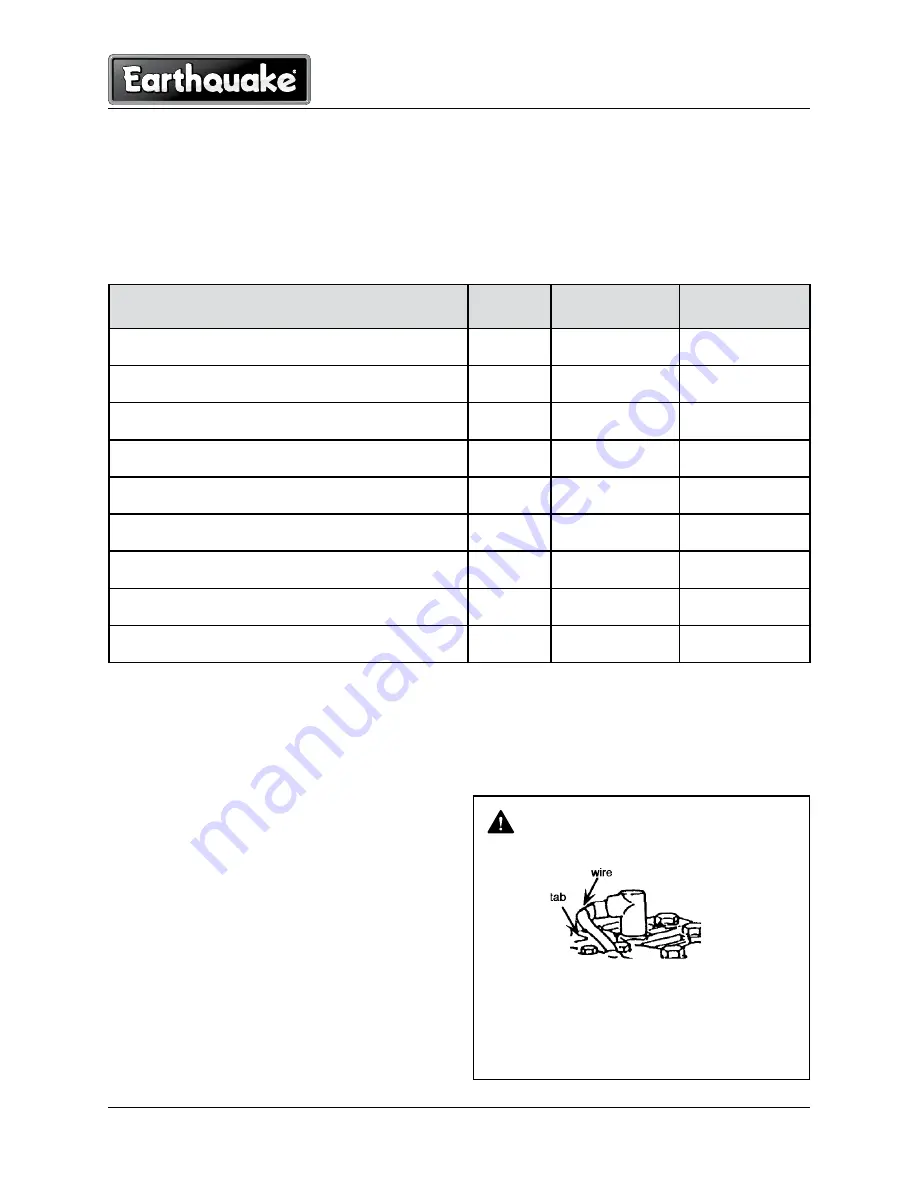

WaRning

to PREVEnt ACCidEntAL StARtinG:

EnGinE muSt BE tuRnEd oFF And CooL,

And SPARk PLuG WiRE muSt BE REmoVEd

And SECuREd FRom SPARk PLuG BEFoRE

ChECkinG And AdjuStinG EnGinE oR

EquiPmEnt.