Operator's Manual

Rolling String Trimmer 600050V, 600050B

Check for parts online at

www.getearthquake.com

or call 800-345-6007 M-F 8-5

14

Operator's Manual

Rolling String Trimmer 600050V, 600050B

Check for parts online at

www.getearthquake.com

or call 800-345-6007 M-F 8-5

SERViCE And AdJuStmEnt

how to Replace the trimmer Line

For the best performance, use a heavy gauge (0.155”

diameter) trimmer line. Cut the length of the trimmer

line to 1.5 inches. Use the length guide, located on

the shield, to make sure the trimmer line is the correct

length.

Do not allow the length of the lines to vary more than

one inch. This is important to make sure the trimmer

head is balanced and does not vibrate.

IMPORTANT: To extend the life of the trimmer line,

keep the trimmer line moist. If not kept moist, the

nylon trimmer line will become dry and brittle.

Keep extra trimmer line in a can of water. The

line will then stay flexible and easy to change. A

flexible line will also last much longer.

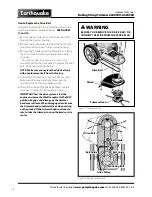

waRning

bEfoRE You inSPECt, CLEAn oR SERViCE

thE tRimmER, StoP thE EnginE. mAkE SuRE

thAt ALL moVing PARtS hAVE StoPPEd.

diSConnECt thE WiRE fRom thE SPARk

PLug.

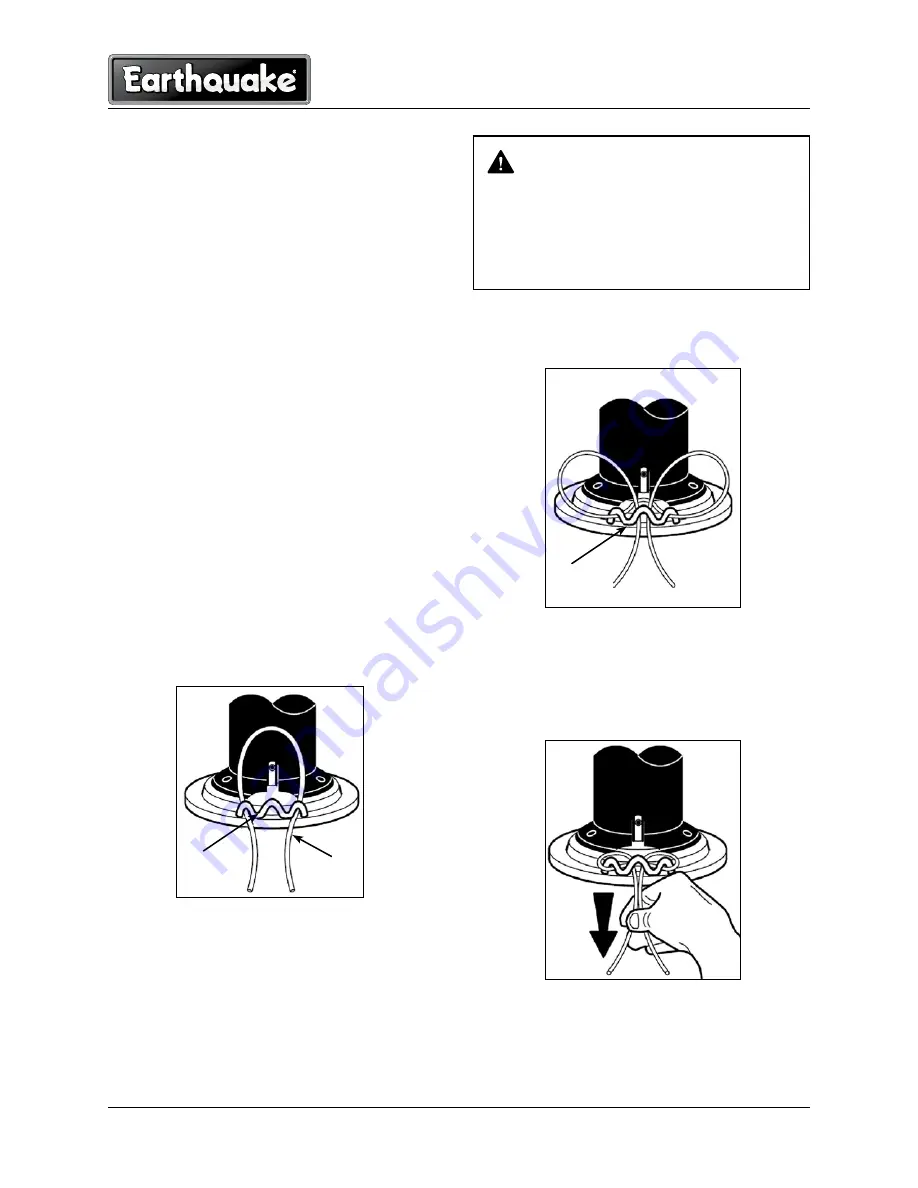

how to Change trimmer Lines

When the trimmer line becomes worn to half of the

original length, replace the trimmer line as follows;

1. Stop the engine. Wait for all moving parts to stop.

. Remove the worn trimmer line from the line retainer.

3. First, thread the ends of the new trimmer line

through the outside loops.

SEE figuRE 12.

4. Next, take the ends of the line, cross over the line

retainer, and thread the ends through the center

hold.

SEE figuRE 13.

5. Then, check to make sure that the ends of the line

are event.

SEE figuRE 14.

Figure 14: Check ends of line

Figure 13: Threading trimmer line

through center hold.

Line

Retainer

Figure 12: Threading the new trimmer

line.

Line

Retainer

trimmer

Line